Video Friday is your weekly selection of awesome robotics videos, collected by your friends at IEEE Spectrum robotics. We’ll also be posting a weekly calendar of upcoming robotics events for the next few months; here's what we have so far (send us your events!):

ICRA 2022: 23–27 May 2022, Philadelphia

ERF 2022: 28–30 June 2022, Rotterdam, the Netherlands

CLAWAR 2022: 12–14 September 2022, Açores, Portugal

Let us know if you have suggestions for next week, and enjoy today's videos.

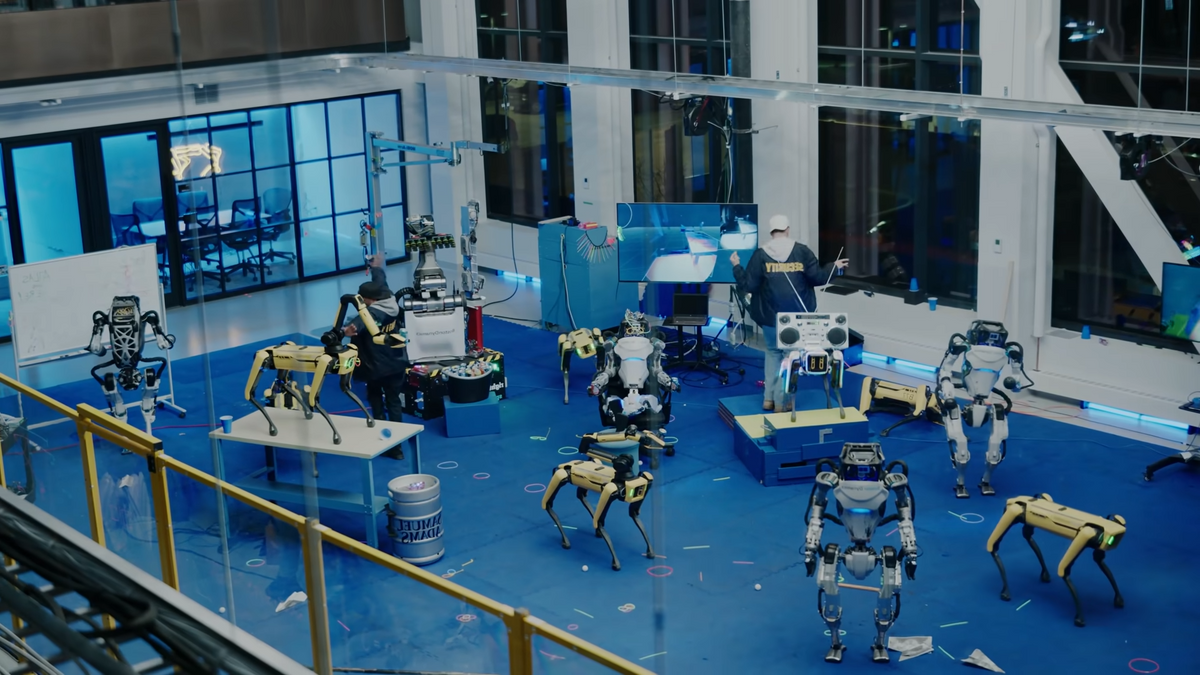

Boston Dynamics put together a behind-the-scenes video of sorts about the Super Bowl commercial they did in collaboration with some beer company or other.

One thing that low-key bugged me about this is how in the behind-the-footage scenes, it's obvious how much separation exists between the actors and the Atlas robots, while in the actual commercial, it looks like the humans and robots spend a lot of time right next to each other.

[ Boston Dynamics ]

Power-line perching could be an easy way for urban drones to keep their batteries topped up, but landing on power lines can be tricky. Watch this video until the end to see a drone fly a trajectory to end up in a perching pose underneath a demo line and upside-down!

[ GRVC ]

This finger motion pleases me.

The two chambers of the soft, pneumatic finger are actuated manually, using two large syringes filled with air. Flicking not a result of fast actuation but of the natural compliance and springiness of the actuator. The compliance inherent to the finger effectively compensates for the inaccuracies in human actuation, leading to robust behavior.

[ TU Berlin ]

Happy Valentine's Day from RightHand Robotics!

Once upon a time two Spots embarked on a mission to find true love. After valiantly overcoming many obstacles, they finally met each other. Sparks were bound to fly in this meeting of the purest hearts. Legend has it that they lived happily ever after.

Sparks flying would be bad, no?

[ Energy Robotics ]

The "new" ASIMO was announced in November of 2011. For a decade-old platform, this performance is still pretty good.

[ YouTube ]

The Apellix Opus X8 Softwash (SW) system cleaning the University of Florida Shands Hospital building in Jacksonville, Florida. The portion of the hospital shown in the video is inaccessible by lifts, impractical to scaffold, and rope access would have been expensive and time-consuming.

[ Apellix ]

NeuroVis is a neural dynamic visualizer that connects to the Robot Operating System (ROS). It acts as a ROS node named “NeuroVis” that receives six topics as inputs: neuron name, connection, updated weight, neuron activity, normalization gain, and bias. In addition, the program can be employed along with a simulation and operates in parallel to the real robot.

[ Brain Lab ]

Thanks, Poramate!

We present the design of a robotic leg that can seamlessly switch between a spring-suspended and unsuspended configuration. Switching is realized by a lightweight mechanism that exploits the alternative configuration of the two-link leg. This allows us to embed additional functionality in the leg to increase the performance in relation to the locomotion task.

Aerial robots can enhance their safe and agile navigation in complex and cluttered environments by efficiently exploiting the information collected during a given task. In this paper, we address the learning model predictive control problem for quadrotors. We show the effectiveness of the proposed approach in learning a minimum time control task, respecting dynamics, actuators, and environment constraints.

[ ARPL ]

Meet the team that may be least likely to achieve the fastest time at the Self Racing Cars competition at Thunderhill Raceway.

I'm a fan anyway, though!

[ Monarch ] via [ Self Racing Cars ]

AeroVironment’s team of innovative engineers discuss our collaboration with NASA/JPL to design and develop the Ingenuity Mars Helicopter.

[ AeroVironment ]

We are excited to announce the availability of Skydio 2+, our newest drone, which adds important battery-, range-, controller-, and autonomy-software improvements. Ready for Skydio 3D Scan and Skydio Cloud, Skydio 2+ provides the smartest and most efficient solution for accurate asset inspections, small-area mapping, and accident-scene reconstruction.

[ Skydio ]

A large dust storm on Mars, nearly twice the size of the United States, covered the southern hemisphere of the Red Planet in early January 2022, leading to some of NASA’s explorers on the surface hitting pause on their normal activities. NASA’s Insight lander put itself in a "safe mode" to conserve battery power after dust prevented sunlight from reaching the solar panels. NASA's Ingenuity Mars Helicopter also had to postpone flights until conditions improved.

[ NASA ]

This GRASP on Robotics talk is by Ankur Mehta at the University of California, on "Towards $1 Robots."

Robots are pretty great—they can make some hard tasks easy, some dangerous tasks safe, or some unthinkable tasks possible. And they’re just plain fun to boot. But how many robots have you interacted with recently? And where do you think that puts you compared to the rest of the world’s people? In contrast to computation, automating physical interactions continues to be limited in scope and breadth. I’d like to change that. But in particular, I’d like to do so in a way that’s accessible to everyone, everywhere. In our lab, we work to lower barriers to robotics design, creation, and operation through material and mechanism design, computational tools, and mathematical analysis. We hope that with our efforts, everyone will be soon able to enjoy the benefits of robotics to work, to learn, and to play.

[ UPenn ]

This week's CMU RI Seminar is by Jessica Burgner-Kahrs from University of Toronto, Mississauga, on continuum robots.

[ CMU RI ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.