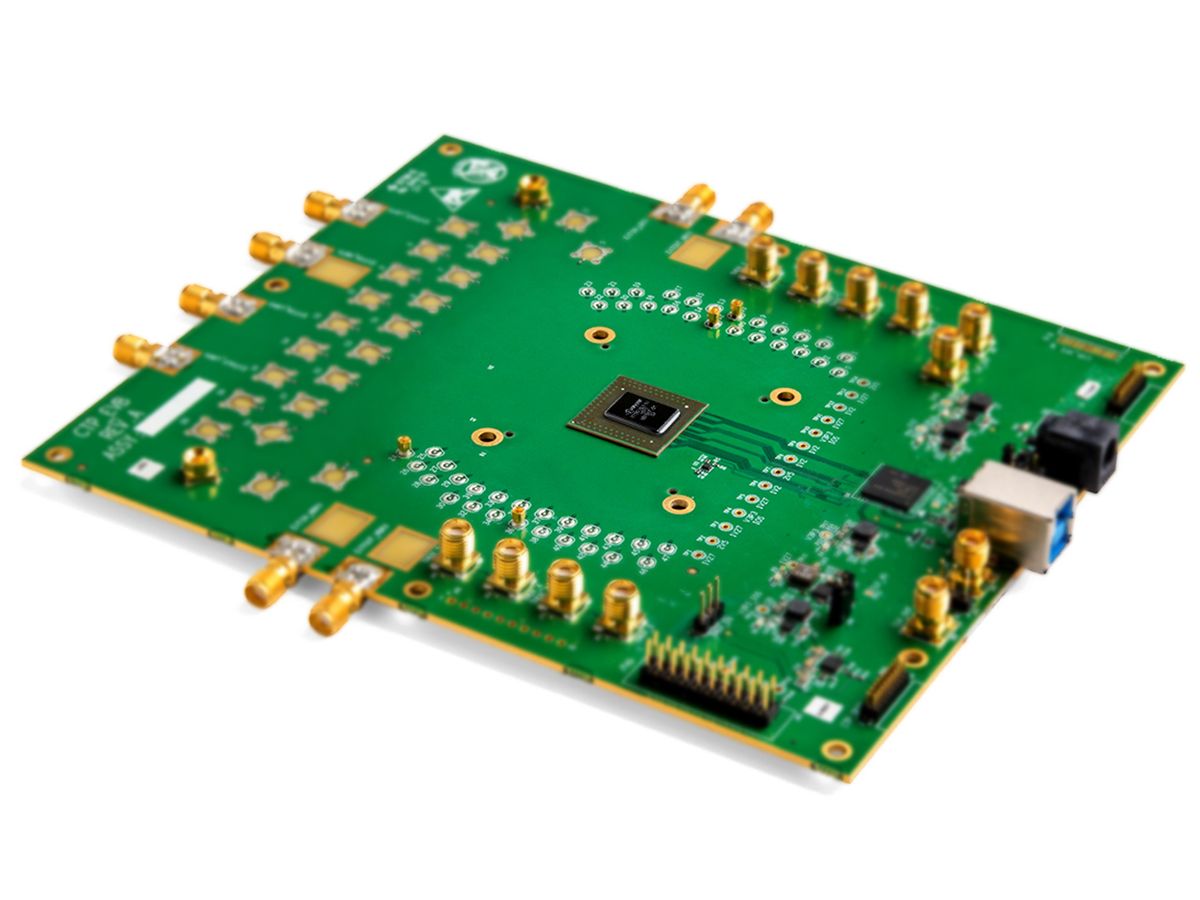

Last week, Israeli radar chip startup Vayyar Imaging released a new, higher resolution 3D imaging radar chip it expects will appear in applications as broad as home security, infotainment, and elder care. The resolution is higher, because it packs an unprecedented 72 transceivers on a chip that has its own digital signal processing circuitry. But the image it creates is nothing like a visible light camera’s, and that’s the key, according the company’s CEO and cofounder Raviv Melamed.

“One of the biggest problems, if you want to monitor people in their home, is privacy,” says Melamed. “Obviously, the best thing to have is a camera, but nobody really wants a camera in the house, especially when people can hack in.” He thinks Vayyar’s chip, which forms images at radar frequencies between 3 GHz to 81 GHz, can provide all the information needed for a home security system without any of the identifying data that impinges on people’s privacy.

Because some of these wavelengths let it see through walls, a single chip can cover a whole apartment. The 72-transceiver system can tell people and pets from everything else in an apartment, but it can’t identify them as individuals. It can determine their rough location and body position (standing, sitting, prone) but not the details of what they’re doing.

“If you have a sensor able to monitor movements—say if somebody fell down, or breathing rates—without putting anything on you, and without compromising your privacy, then you have a very interesting device,” Melamed says. “It’s just like a camera, but without the privacy issues.”

The number of transmitters and receivers—72 each—was a trade-off between chip size, and therefore cost, and capability, the company says. But it would be possible to make even higher resolution chips. And some applications would require multiple chips, Melamed says. One example would be a system to detect non-metal weapons on people at airports, because the chip’s radiation can penetrate clothing to find such items.

The chip also includes a built-in digital signal processing system. The aim here is to preprocess some of the image data, so the amount that has to be transmitted from an IoT device to the cloud is reduced.

Samuel K. Moore is the senior editor at IEEE Spectrum in charge of semiconductors coverage. An IEEE member, he has a bachelor's degree in biomedical engineering from Brown University and a master's degree in journalism from New York University.