Photovoltaic cells are finding a host of new applications, even powering airplanes. An example is the Solar Impulse 2 plane, which is blanketed by photocells that can keep it airborne indefinitely. Although their conversion efficiency, at 22 percent, is comparatively good, covering 200 square meters with the 130-micrometer-thick cells adds significant weight to the plane.

A team of scientists from the Johannes Kepler University Linz in Austria reported in the 25 August edition of Nature Materials Online that they have created prototype solar cells that are a mere 3 micrometers thick.

“We are interested in developing a solar cell technology that is the most lightweight and has the highest power per weight that is possible in a research lab,” says physicist Martin Kaltenbrunner, the spokesperson for the team. Although the ultrathin cells’ conversion efficiency is 12 percent, they weigh about 100 times less than the lightest solar cells currently available. The researchers reached an interesting milestone: A square meter of solar cell weighing 5.2 grams produced 120 watts. “It is an absolute record in power per weight,” says Kaltenbrunner.

For their light harvesting material, the Austrian researchers used organolead halide perovskite, a hybrid organic material that is now viewed as a promising alternative to silicon. Says Kaltenbrunner:

The neatest thing about the perovskites is that they are direct band gap materials and can be made very thin, but can still absorb a lot of light. So a couple of hundred nanometers are actually enough to collect all the photons in the absorption range that it has and convert them to electron-hole pairs.

For the creation of these thin perovskite layers, the scientists used solution processing to deposit the thin layer on the transparent electrode. “We used that technique but we had come up with a new method to get a nice pinhole film on a very rough substrate,” says Kaltenbrunner. “Our foils are very thin but also very rough, and it is challenging to process nanometer thick layers on them without having too many defects.” The other, non-transparent electrode, which could be either gold, aluminum or chrome, also serves to increase the efficiency of the cell by reflecting back the photons that still passed through. The total thickness of the device, including the two 100-nanometer-thick electrodes, the substrate, and protective layers is 3 micrometers.

The researchers’ processing tools allowed the creation of films only as large as about 10 centimeters, but in the future, roll to roll processing should be possible, says Kaltenbrunner.

At this stage of the research, the device is vulnerable to oxygen and water, but functions at full capacity with artificial sunlight for several days. The team says it made demonstrators that operate in air, and that a half year later, the gadgets are still functional. “We had this little zeppelin and a few days ago we tried it, and [the solar panel] still propels it."

Because these layers are so thin, the film is very flexible and elastic, which results in other interesting advantages besides low weight. By creating the foil on a stretched substrate and then releasing the tension, the deposited foil wrinkles up. “You get this microtexture of tiny valleys that collect more light and, per unit area, we get a higher efficiency,” says Kaltenbrunner. The flexibility provides yet another advantage: “You fabricate on a large scale in a flat geometry a very thin electronically functional foil, and then you laminate it to whatever object you want,” Kaltenbrunner points out. “The car industry is very interested in this.”

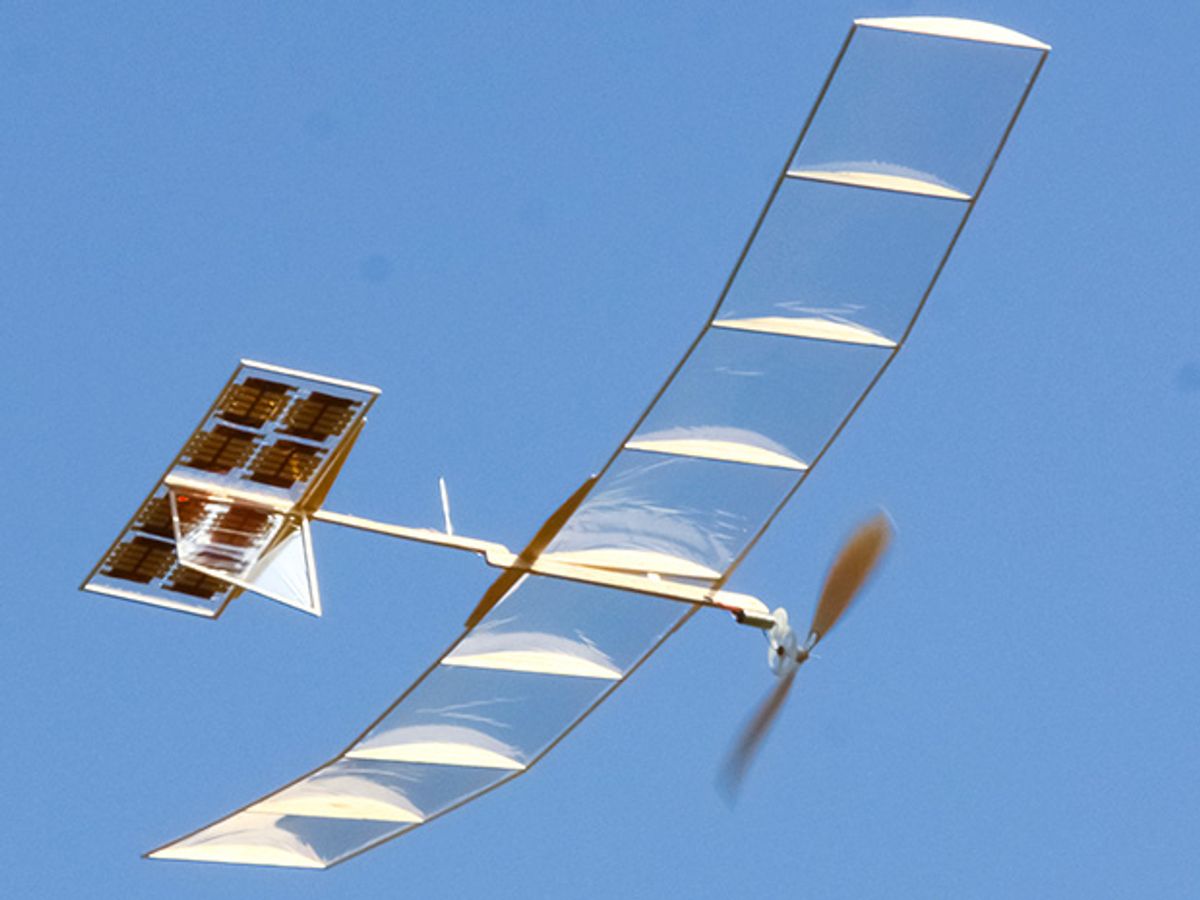

Photovoltaics that are almost weightless may end up in everything that flies, such as weather balloons, small unmanned planes, and even drones, says Kaltenbrunner.

What about applications in space? It is still too early to answer this question because it is not known whether the film could withstand the intense particle radiation. “It would be really exciting to have partners on board that can test this, like ESA or NASA,” says Kaltenbrunner. For example, one could have solar sails that might also be solar cells. “Interestingly, this was the driving force to thin down solar cells and make them lightweight.” Kaltenbrunner explains. “This started in the 1980s; there were papers on silicon solar cells on plastic substrates just for this purpose.”