Your typical mobile phone user—who may be cursing his or her smart phone because the battery runs out after just a few hours of normal usage—may not be thinking: What this phone really needs is a spectrometer built into it. But if they knew what spectrometers could do, they might change their minds.

How about a smart phone that you could wave over the fruit and vegetables at the grocery store in order to determine whether they are ripe? That’s the kind of Star Trek Tricorder, gee-whiz technology that gets people to buy a smart phone.

Researchers at the Technische Universität Dresden and the Fraunhofer Institute for Electron Beam and Plasma Technology in Germany have developed a technology that could enable exactly that kind of capability. The German researchers have created a novel, miniature spectrometer, enabled by metallic nano-antennas, small enough to fit onto a mobile phone.

In addition to checking on the ripeness of produce, it could also serve in a more critical role as a tool for diabetes patients to monitor their blood-sugar levels. Of course, using nanotechnology to make your mobile phone into a portable medical monitor is not a new concept. But what distinguishes this latest research out of Germany is that the thin-film manufacturing technique employed makes the spectrometer sensor compatible with mass production.

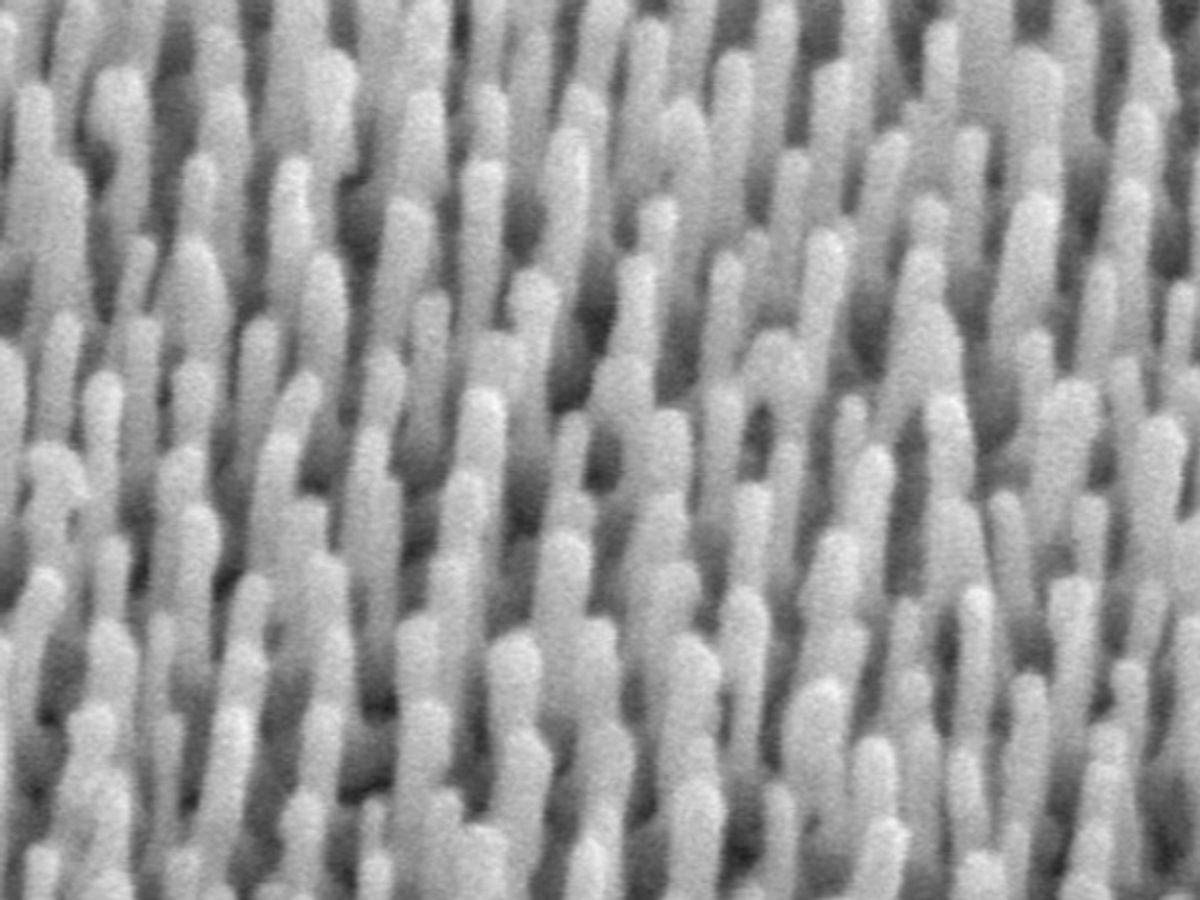

Even if you could shrink a spectrometer—which measures light over a specific portion of the electromagnetic spectrum—to its smallest physical dimensions using conventional techniques and have it still work, it would not fit onto a mobile phone. The trick employed by the German researchers is the use of metallic nanowires that serve as nano-antennas to absorb, amplify and redirect the light onto the light detector—a CCD/CMOS chip that houses the antenna array. This makes it possible to miniaturize the spectrometer to a scale never conceived of before. The only limit to the size of the spectrometer is how small you could make the CCD/CMOS chip.

The three-year-long research project, dubbed "nanoSPECS", began in August of this year. Naturally, it is still at a preliminary stage, but the researchers expect that by the end of the project, they will be able to manufacture the graded antenna-array to the 8”-wafer size.

If the German researchers are successful, at that point you will have a smart phone that you can wave over a plum or canteloupe to pick the best, and you might even have a way to power the phone so that it would last as long as a Tricorder.

Image: Fraunhofer

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.