Through a Lens Sharply

Tiny shape-shifting lenses that mimic the lens of the human eye could transform the multibillion-dollar camera-phone market

The Camera Phone is one of the hottest-selling items in all of consumer electronics, with anticipated sales this year of 170 million units. The little gadgets have become so ubiquitous that hardly anyone finds it odd anymore to see tourists squinting with one eye while pointing their cellphones at a Buddhist temple, a Greek statue, or a New York City skyscraper. It's easy to see why analysts expect that this year camera phones will outsell conventional digital cameras and traditional film cameras combined.

But as anyone who has ever seen them can attest, the images that come out of camera phones leave plenty to be desired. Part of the problem is their CMOS imaging chips, which typically have a sensor array of only about 300 kilopixels--a quarter or less of the number in a low-end digital camera. Of course, semiconductor industry fundamentals ensure that 1-megapixel camera phones will soon be the norm. When they are, however, the only thing we may see more clearly is the other weakness of these cameras: their tiny, fixed-focus lenses, which have poor light-gathering and resolving power.

We have a solution. It's modeled on the human eye, with its remarkable optical capabilities. We call it the FluidFocus lens. Like the lens of the eye, this lens, which we built at Philips Research Laboratories, in Eindhoven, the Netherlands, varies its focus by changing shape rather than by changing the relative positions of multiple lenses, as high-quality camera lenses do. Our tests of a prototype FluidFocus lens showed that it can be made nearly as small as a fixed-focus lens. Fixed-focus lenses use a small aperture and short focal length to keep most things in focus, but at the sacrifice of light-gathering power and therefore of picture quality.

At the same time, our prototype lens delivered sharpness that is easily on a par with that of variable-focus lenses. In fact, the optical quality of a liquid lens combined with a megapixel imaging chip could soon give cellphone snapshots quality that rivals images from conventional--and much bulkier--digital cameras.

The superior capabilities of FluidFocus lenses should make them ideal not only in camera phones but also in products whose design constraints demand a tiny but capable optical system. Just a few examples are pocket-size conventional digital cameras, PDA cameras, webcams, hidden security cameras, DVD recorders, and endoscopes. And with extensive bioengineering, it's even possible to imagine these lenses being a key component of a future implantable artificial eye--long a dream of ophthalmologists and science-fiction writers. The superhuman, zooming vision first popularized by the hero of the 1970s U.S. TV series "The Six Million Dollar Man" is still far off, but now, at least, we have an idea of how it might be achieved.

Conventional Autofocus Systems are not practical in today's camera phones and other portables, because they use motors and gears to shift the position of the lenses. Those assemblies are difficult to miniaturize and are vulnerable to wear. But our liquid-based lens has no moving parts or mechanical actuation, which makes it more efficient and potentially much longer-lived. Such features are a big plus in security cameras, for example, which are constantly refocusing.

The human eye focuses on objects at different distances by contracting and expanding muscles attached to the lens. The muscles change the shape of the lens and alter its focal length.

Our FluidFocus lens, on the other hand, uses electrostatic forces to alter the shape of a drop of slightly salty water inside a glass cylinder 3 millimeters in diameter and 2.2 mm long. One end of the cylinder points toward the image plane; the other is directed at the subject being imaged [see diagram, Shape Shifter].

Shape Shifter:

The FluidFocus lens comprises a volume of water [blue] covered by a volume of oil [tan] inside a glass cylinder [light blue]. At the inner surface of the glass are cylindrical layers of an electrode, an insulator, and, on the very inside, a water-repellent material.

With no voltage on the electrode, the water surface is convex [top]. And because the refractive index of oil is greater than that of water, parallel light rays passing through the meniscus--the interface between the water and the oil spread out.

A voltage on the electrode attracts water molecules toward the cylinder's surface, making it act lessrepellent, and the water surface becomes concave [next diagram]. Here, parallel light rays passing throughthe meniscus converge at a focal point.

The cylinder containing the water drop is filled with oil. Around the inside walls of the cylinder is a water-repellent Teflon-like coating, and behind this coating is an electrode. Basically, the water and the oil make up the lens, and the shape of the interface between the two--the meniscus--determines its focal length. Changing the voltage on the electrode changes the shape of the interface and alters the focal length of the lens.

The lens exploits surface-tension characteristics of fluids. The surface of a column of water in a clean glass cylinder forms a bowl-shaped meniscus. Because the molecules in the glass attract water molecules, the liquid surface curves upward near the clean cylinder wall. If the glass is greasy, the water surface curves downward near the wall, because grease repels water.

At the center of the meniscus, the water surface is nearly flat because of gravity. Without gravity the water surface would be spherical--the ideal shape for a focusing lens. In our lens, we cancel the effect of gravity by keeping the drop small and covering it with oil, which doesn't mix with the water. To completely cancel the effect of gravity, the oil must have the same density as the water, because only then does gravity attract the oil and the water with equal force. In our lenses, we use a mixture of special silicone oils (phenylmethylsiloxanes) with that identical density. The result is a water-to-oil interface whose shape will hold with any orientation of the cylinder but can be changed by a voltage on the surrounding electrode.

The optical power of the lens that forms at the surface between the oil and the water depends on two things: the curvature of the meniscus and the difference between the refractive indices of the oil and water. The refractive index--the ratio of the speed of light in a vacuum to its speed in the medium--characterizes the amount by which light bends when it passes from one medium to another. The curvature of the meniscus depends on the diameter of the cylinder and on how strongly the cylinder wall repels or attracts the water. That attraction or repulsion changes with the voltage on the electrode.

Within the next year or two our FluidFocus lenses may be enhancing the resolution of pictures from cellphone and PDA cameras

In our lens, the coating on the inside walls of the cylinder repels water so strongly that the water does not even touch it: there is a very thin oil layer between the coating and the water. So the water touches the cylinder only at the flat surface on one end, which has no water-repellent coating. With no voltage on the electrode, the meniscus is hemispherical, with the center bulging outward beyond the ring where the water comes closest to the cylinder. However, a voltage on the electrode attracts the water and produces a concave meniscus, forcing the edges beyond the center.

If liquid-filled lenses are such a great idea, why weren't they perfected long ago? There are three main reasons: the difficulties of counteracting the effects of gravity, of containing the fluid so its shape can be precisely controlled, and of then deforming the fluid in a controlled way.

In the 17th century, the English scientist Stephen Gray built microscopes using water drops, creating water-drop lenses with a diameter so small--about 0.3 millimeters--that their curvature was not strongly influenced by gravity. Gray found that the images these lenses created were quite good, thanks to the smooth surface of the drop. He kept the drops from moving around by placing them in holes drilled in a plate. Different hole diameters led to different drop curvatures and different magnification factors.

In 1940, Robert Graham, working at Ohio State University, in Columbus, attempted to make a humanlike lens by changing the amount of liquid between two flexible membranes. He was not successful. The liquid leaked out of the membranes, and worse, elastic tension in the membranes made it impossible to control the lens shapes with enough precision to produce undistorted images. Moreover, the effects of gravity made the lens's shape dependent on its orientation. (For the human eye, these problems are not severe, because the lens is surrounded by fluid. Since the membrane that surrounds the lens is very thin, distortions due to elastic tension are small.)

Our approach in designing the prototype lens starts with Gray's 17th-century idea of keeping the drop centered in a hole. It also borrows from the discoveries of two 20th-century researchers, Aleksandr Froumkine and Christopher Gorman.

In 1936, Froumkine began experimenting with the use of electric fields to change the shape of a water drop sitting on a metal surface. This phenomenon, in which an electric field pulls the drop toward the plate, is called electrowetting: the drop wets, or contacts, the surface better when it is attracted by an electric field.

Using the electrowetting technique, Gorman and his colleagues at Harvard University, in Cambridge, Mass., made the first variable-focus lens in 1995 by replacing the metal plate with a transparent conducting plate. They believed that these lenses could have applications in adaptive optics for astronomical telescopes, a technique that compensates for atmospheric effects by dynamically changing the shape of a mirror [see "Taking the Twinkle out of Starlight," IEEE Spectrum, December 2003]. An intrinsic problem with such lenses is that they are difficult to sabilize because they do not center themselves about the optical axis--the line that runs through the center of the aperture.

In 2000, Bruno Berge and Jerome Peseux at the Universite Joseph Fourier, in St. Martin d'Heres, France, improved on Gorman's design by covering the transparent electrode with an insulating film, and by adding the means for centering the drop. Berge is currently pursuing commercialization of his liquid lens approach at Varioptic S.A. in Lyon, France, a company founded in 2002.

Our solution to the centering problem combines electrowetting with Gray's old concept of centering the drop in a cylindrical hole--in our case, the glass cylinder--and placing the electrode that creates the electric field around the inside of the cylinder, instead of on the ground plate.

One Important Advantage of our liquid lens is that it can be very small. In fact, as Gray showed us, smallness is inherently advantageous, because it minimizes the effects of gravitational pull on the liquid. In addition, miniaturization makes liquid lenses more powerful, because the electrostatic forces between the liquid and the inner surface of the cylinder become stronger as the lens size shrinks.

This property makes small electrowetting lenses very fast. Our prototype can refocus in 10 milliseconds, much faster than the human eye, which can refocus in about 200 ms. Scaled to the size of a human eye lens, the refocusing time would increase to 50 ms, which would still be four times faster than that of the eye.

So how good are these lenses? The optical power of a lens is specified in diopters, a measure of how much the lens can bend light. The dioptric value of a lens is proportional to the inverse of the radius of curvature of the lens in meters. The closer objects are to a lens, the more the lens must bend the light to bring them into focus. So when an object is far away, a lens needs less optical power to bring it into focus than it does when the object is near. Our liquid lens changes its focus by changing its optical power through the change of the water drop's radius of curvature with voltage on the electrode.

The strength of eyeglasses is also expressed in diopters. So, for example, eyeglasses of +2 increase the optical power of the eye by 2 diopters, allowing the wearer to see things that are close.

The optical power of our lens, with its inner cylinder diameter of 3 mm, can vary over a range of 150 diopters. This is accomplished by changing the meniscus between hemispherical (its radius equal to half the diameter of the cylinder) and concave (its radius approximately equal to the diameter of the cylinder). If it were the same size as a human lens, its optical power range would be about 50 diopters--12 times as large as the optical power of the human eye, which has a range of about 4 diopters.

The main optical elements of the human eye are the cornea, the iris, the lens, and the retina. The cornea is the transparent dome that covers the front of the eye and serves as its outer window. Next comes the iris, the colored part of the eye, which forms the variable aperture of the system--that is, the pupil, which opens or closes to admit more or less light. Behind the iris is the deformable lens, the part of the eye that is analogous to our liquid lens, which focuses the light on the curved retina at the back of the eyeball.

In the human eye, the main optical power of the lens system comes from the cornea and is about 40 diopters. The typical deformable human lens is about 9 mm wide and 4 mm thick. The lens has an optical power of between +20 and +24 diopters to bring into focus objects that are closer or farther away.

Eye Of The Beholder:

In the human eye, the cornea provides the main optical power, and the lens supplies the variable focus. Muscles attached to the lens change its curvature to focus on objects at different distances. The closer an object is, the more rounded the lens must be in order to project a focused image onto the retina at the back of the eye.

The human lens consists of several fine layers of transparent tissue with different indices of refraction ranging in the various layers from 1.406 in the center to about 1.386 in the outer layer. This gradient in the refractive index makes the focal length independent of wavelength--that is, it bends all colors of light equally. It is an important property for creating sharp images.

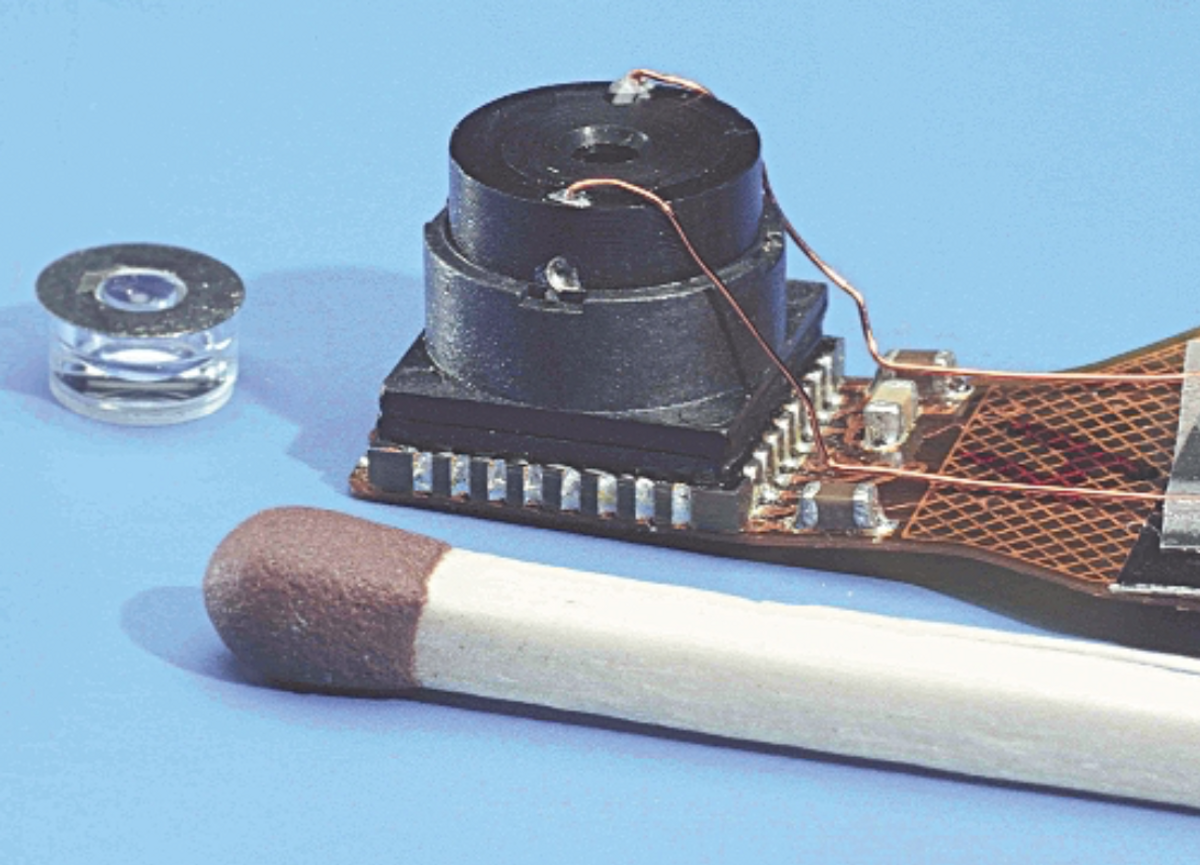

To Demonstrate The Advantages of our liquid lens, we built a digital camera just 5.5 mm high and 4 mm across [see diagram, " All in Focus"]. At the back of the camera is a CMOS imager with a 640-by-480-pixel sensor array. Directly in front of the CMOS imager is a plastic lens, which allows the image to be projected sharply onto the flat CMOS image sensor. The eye does not need such a lens because the image sensor in the eye (the retina) is curved.

In front of this plastic lens is the liquid lens in its cylindrical glass housing, with the cylinder's outer diameter measuring 4 mm and its inner diameter 3 mm. The oil side of the liquid lens is close to the imager. A glass plate seals the liquid lens on the side near the imager, and a truncated glass sphere mounted on a flexible membrane seals it on the opposite side.

The truncated sphere allows the focal length of the camera to be independent of wavelength--as with the human eye. This property is important because it focuses all the wavelengths that make up the image at the same point, leading to a sharp image. The membrane allows the volume of the liquids to expand or contract depending on the temperature. In front of the truncated glass sphere is another plastic lens, which, like the cornea of the eye, provides the main optical power. In front of this plastic lens is the fixed aperture.

By changing the voltage on the electrode of the liquid lens, we were able to focus on objects at distances anywhere from 2 centimeters up to infinity. To do so, we varied the focal length from 2.85 mm to 3.55 mm [see photos, " From Here to Infinity"].

In contrast to the human eye, which is embedded in a temperature-controlled system, our lens must operate over a range of temperatures. For portable applications, the lens must work between -30 degrees C and +60 degrees C and survive temperatures between -40 degrees C and +85 degrees C. Because such a wide range requires special liquids, we added large amounts of salt or antifreeze to the water in our prototype camera lens to lower the freezing point sufficiently without adversely affecting the image quality.

There is, however, one property for which our lens probably can't beat the human body, and that is lifetime. No autofocus camera that we know of can operate all day long, every day, for 80 years or more. We have, however, varied the focus of our liquid lens--from one end of its range to the other--more than a million times without any decrease in performance.

We are now working on a FluidFocus zoom lens. Optical zooming requires at least two lenses--one to change the magnification, the other to refocus the image. In principle, changing the magnification by moving the lens throws the image out of focus. Conventional cameras keep the image in focus through a system of rods that connect the separate lenses.

We are presently designing a zoom lens system that uses two liquid lenses in series. This lens will work by changing the shapes, and therefore the optical power, of the two lenses, rather than by changing their locations. Compared with conventional zoom lenses, liquid lenses will have two advantages: no moving parts and a very small size at, potentially, a very low cost.

It is even possible to apply the liquid lens in high-quality optical recording systems like DVD recorders, because its resolution can be controlled so it is not limited by lens imperfections but only by diffraction, which restricts the resolution of all lens systems.

The lenses have other intriguing possibilities, too. Replacing the electrode that encircles the inner wall of the glass cylinder with multiple vertical electrodes and adjusting their voltages separately allows tilting of the interface between the liquids, offering the ability to image in directions that are at an angle to the lens axis. A lens that can be tilted and focused could let engineers design video cameras and binoculars that would compensate precisely for hand movement and other undesired motions.

We expect that within the next year or two our FluidFocus lenses will be enhancing the resolution of pictures taken with cellphone and PDA cameras.

Because the liquid lens is based on materials that are, at least in theory, biocompatible, and because refocusing the lens requires very little energy, we can envision (pardon the expression!) future applications to replace a malfunctioning human eye lens. With a zooming feature, we might even far surpass it. Imagine being able to read a car license plate from a kilometer away or the menu in a restaurant window without getting out of your car.

We have plenty of work to do before that can happen. But to make this science-fiction dream a reality, what we'll need most of all is vision.

About The Authors

Benno Hendriks joined Philips Research Laboratories, in Eindhoven, the Netherlands, to work on electron optics in 1990. He switched to optical recording six years later and in 2002 joined the FluidFocus project, specializing in the optics of the liquid lens. He received his Ph.D. in quantum optics at Utrecht University, the Netherlands, in 1989.

Stein Kuiper is the project leader of the FluidFocus effort, which he started in 2000. Earlier that same year, he obtained his Ph.D. in physics from the University of Twente, in the Netherlands.

To Probe Further

Bruno Berge and Jerocircme Peseux reported on their liquid lens work in The European Physical Journal E 3 (2000), p. 159.

Technical details of the FluidFocus lens are published in S. Kuiper and B.H.W. Hendriks, Applied Physics Letters 85 (2004), p. 1128.

A clear explanation of how human eyes and camera lenses work is available at https://www.umiacs.umd.edu/~ramani/cmsc828d/lecture3.pdf.