Three Steps to a Moon Base

Space agencies and private companies are working on rockets, landers, and other tech for lunar settlement

In 1968, NASA astronaut Jim Lovell gazed out of a porthole from lunar orbit and remarked on the “vast loneliness” of the moon. It may not be lonely place for much longer. Today, a new rush of enthusiasm for lunar exploration has swept up government space agencies, commercial space companies funded by billionaires, and startups that want in on the action. Here’s the tech they’re building that may enable humanity’s return to the moon, and the building of the first permanent moon base.

-

1. Getting to the Moon

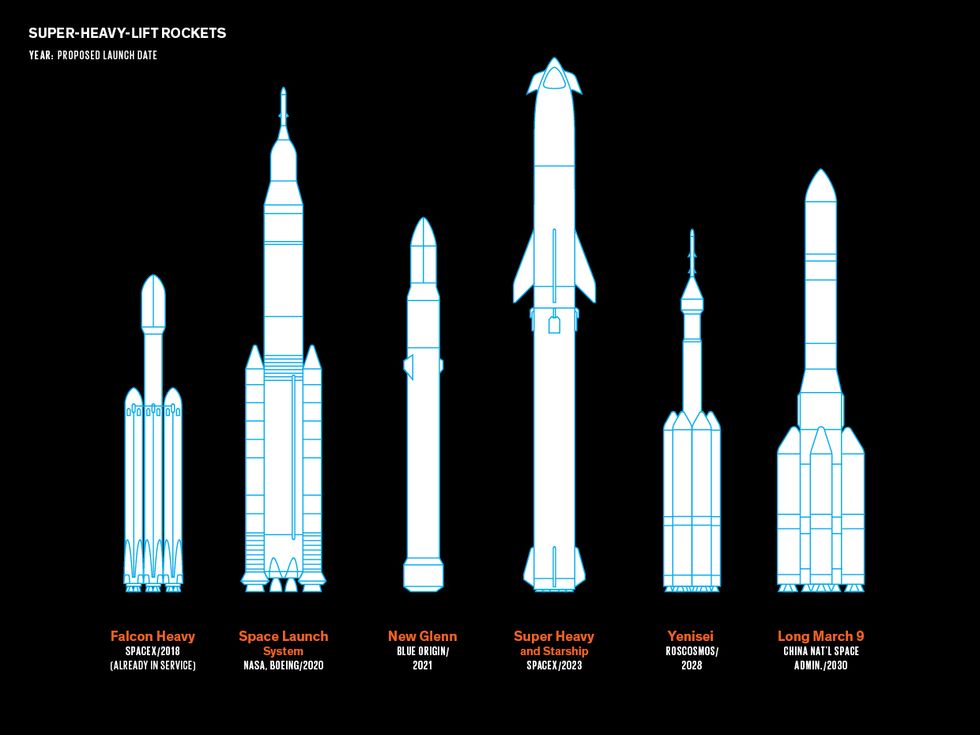

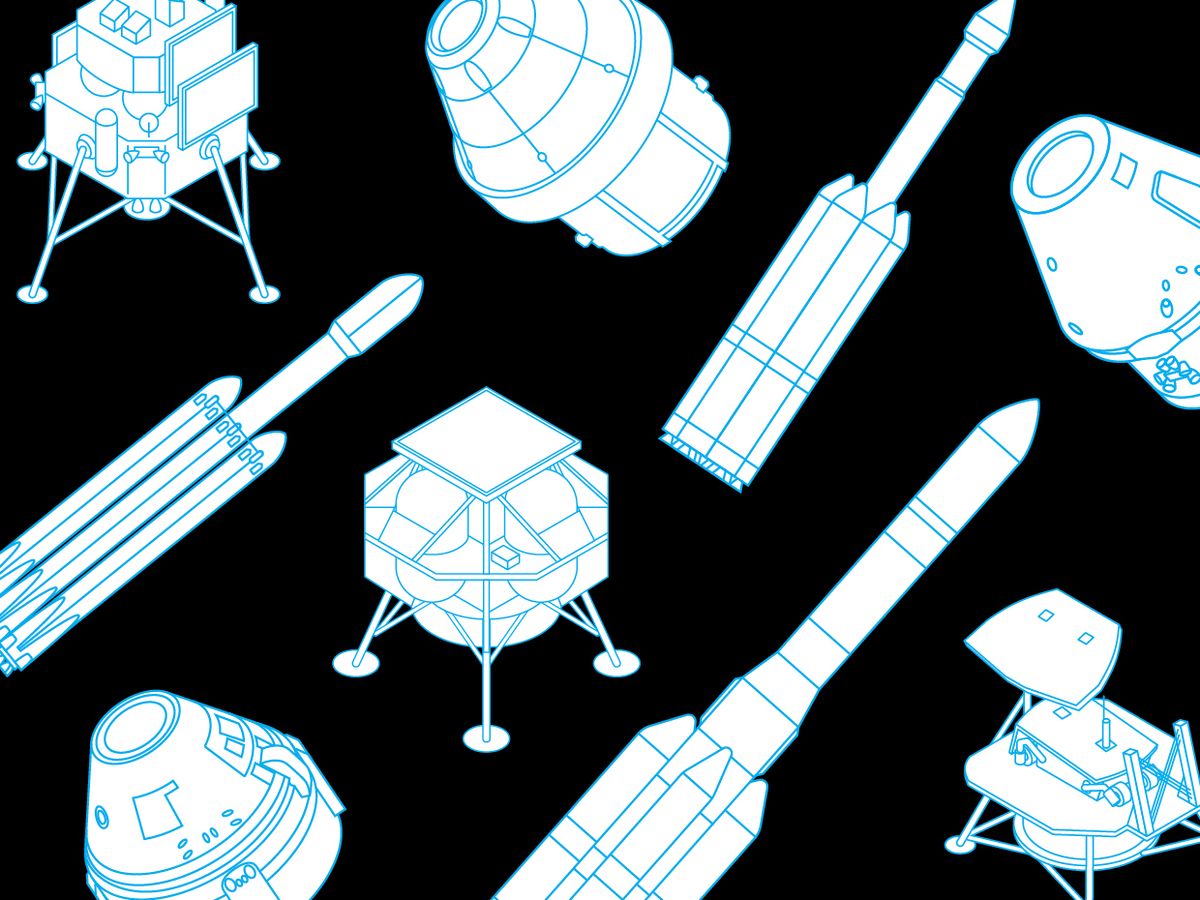

Super-Heavy-Lift Rockets: NASA is relying on the Space Launch System (SLS) for its 2024 lunar return plan—although the rocket is over budget and behind schedule. China is working to upgrade its current Long March 5 rocket (which failed in its second flight) to the Long March 9. Russia says it has finalized the design for its Yenisei rocket, but experts wonder if it will actually get built. Blue Origin and SpaceX’s rockets use reusable stages, which could make them much more economical. SpaceX’s Starship is the most futuristic of the lot, comprised of reusable stages and a built-in crew capsule.

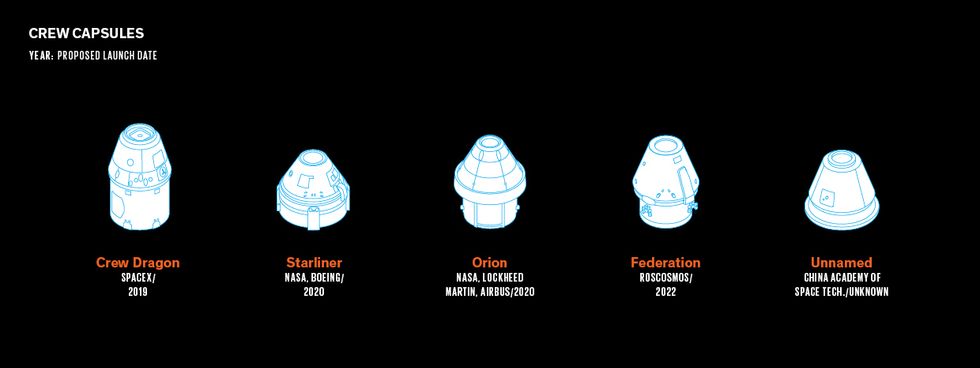

Illustration: James Provost Crew Capsules: The Crew Dragon and Starliner are scheduled to begin crewed flights to the International Space Station this year and next.

Illustration: James Provost -

2. Landing on the Moon

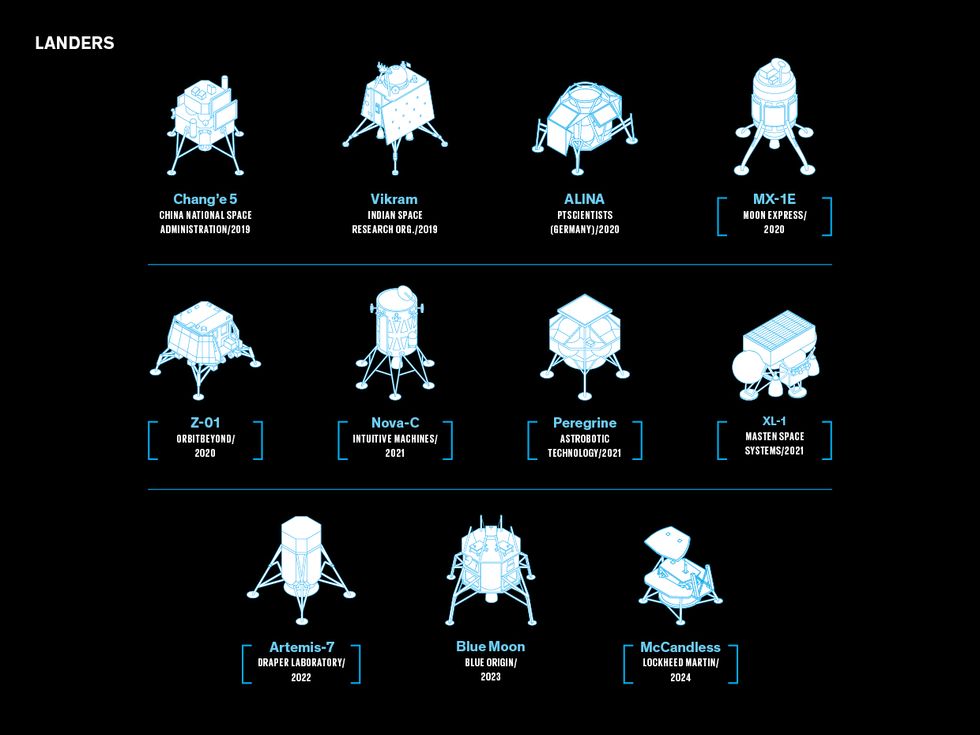

Landers: NASA has pushed for lunar cargo landers by working with companies [in blue brackets] in its Commercial Lunar Payload Services program. In May, its first contracts went to Astrobotic Technology, Intuitive Machines, and OrbitBeyond. But NASA’s work with companies developing crewed landers has only just begun. China’s Chang’e 5 is scheduled to blast off on a sample return mission in December. Blue Origin’s lander could be converted to a crewed vehicle.

Illustration: James Provost -

3. Building on the Moon

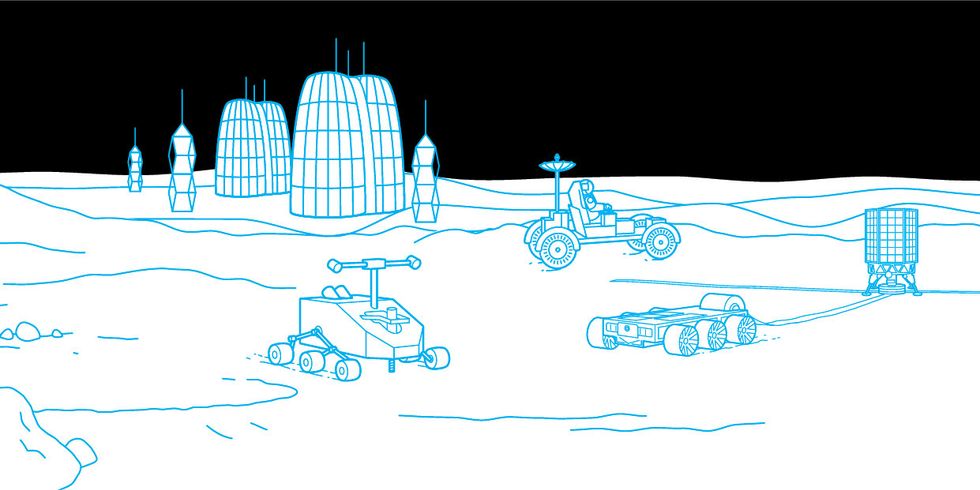

Illustrations: James Provost Once we manage to get humans and their gear to the lunar surface, what happens next? Many companies and researchers are actively pursuing technology projects that will enable a permanent settlement on the moon. Here are a few that we find particularly interesting.

Habitats: The European Space Agency is funding architectural and engineering work for the Moon Village, its proposed cooperative international settlement. See: “Engineers and Architects Are Already Designing Lunar Habitats.”

Mining: Researchers at the Colorado School of Mines and Honeybee Robotics have proposed schemes to mine water ice for the components of rocket fuel. See: “Squeezing Rocket Fuel From Moon Rocks.”

Science: Astrophysicists at the NASA-funded Network for Exploration and Space Science have a plan for a radio observatory on the moon’s far side. See: “Rovers Will Unroll a Telescope on the Moon's Far Side.”

Communications: NASA and MIT’s Lincoln Lab have developed laser systems for high-bandwidth communications between a moon base and Earth. See: “Lunar Pioneers Will Use Lasers to Phone Home.”

Navigation: For precision landings and safe exploration, Astrobotic Technology and Draper Labs have both devised cutting-edge mapping software. See: “Robots Will Navigate the Moon With Maps They Make Themselves.”