When Xiang Zhang first invented an invisibility cloak that worked at optical wavelengths, his son complained that it wouldn’t allow him to easily stroll around unseen, like Harry Potter sneaking through the library.

“My son always joked that, ‘Daddy, if I want to make myself disappear I have to carry a huge cylinder around myself,’” says Zhang, a professor of mechanical engineering at the University of California, Berkeley. The boy wondered why he couldn’t have something more like a sunblock, a spray-on material that rendered him invisible. That may not be such a far-fetched vision, Zhang says.

He and his colleagues have created an extremely thin cloak that works in visible light, made of a metasurface, a special type of metamaterial that is thin enough to be considered two-dimensional. They described the device in last week’s Science.

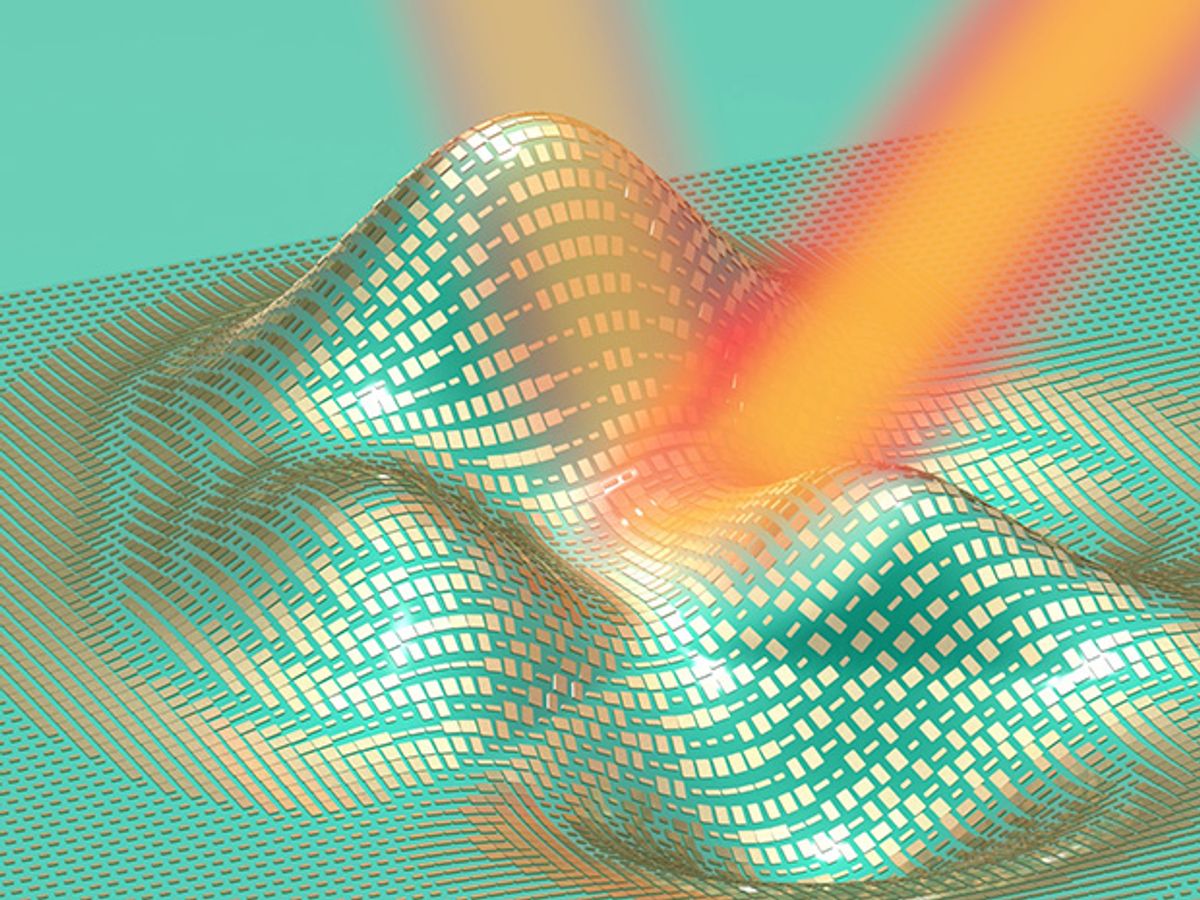

The metasurface is a thin layer of silicon dioxide, on top of which the team inscribed gold blocks, surrounded by the dielectric material magnesium fluoride, that act as nanoantennas. The blocks are approximately 80 nm thick, but they vary in size by as much as 30 percent, so that the metasurface contains six different sizes of nanoantenna.

The antennas resonate at particular wavelengths, absorbing the incoming light and re-emitting it to make it seem as if it’s coming off a flat surface. Because they vary in size, they can cancel out local variations in the phase of the light, a type of interference that would render the hidden object visible.

The cloak worked at wavelengths from 710 to 730 nm, but Zhang says it’s theoretically possible to make materials that can span 300 nm of the spectrum, enough to cover the visible wavelength range.

And while this cloak can only hide stationary objects, it might be possible to use a current to tune the antennas and change their resonance to cope with changes in the object underneath. “That’s our next task, how you make things more adaptive, how you change the shape of something,” Zhang says.

So how long until there’s a practical cloaking device that can effectively cover a boy wizard as he moves about? Zhang says he wouldn’t be surprised to see—or not see—something like that within the next decade. “I think we are getting close to that.”

Neil Savage is a freelance science and technology writer based in Lowell, Mass., and a frequent contributor to IEEE Spectrum. His topics of interest include photonics, physics, computing, materials science, and semiconductors. His most recent article, “Tiny Satellites Could Distribute Quantum Keys,” describes an experiment in which cryptographic keys were distributed from satellites released from the International Space Station. He serves on the steering committee of New England Science Writers.