It’s become somewhat of a rite of passage: Any new nanomaterial is eventually offered as an alternative to indium tin oxide (ITO) in displays. We’ve seen the standard offerings of carbon nanotubes and graphene trotted out fairly regularly, and we’ve even seen some pretty exotic offerings like those based on inorganic materials patterned by man-made viruses.

This effort to replace ITO makes sense because it is a relatively scarce resource. And with the explosion of handheld electronic devices, the demand for ITO as a transparent conductor for controlling display pixels has become increasingly acute.

Now there’s a new pretender to ITO’s throne: correlated metals. Researchers at the Penn State Materials Research Institute believe that by using 10-nanometer-thick films of these materials, it’s possible to make large screen displays, touch screens, and even photovoltaics more affordable and efficient.

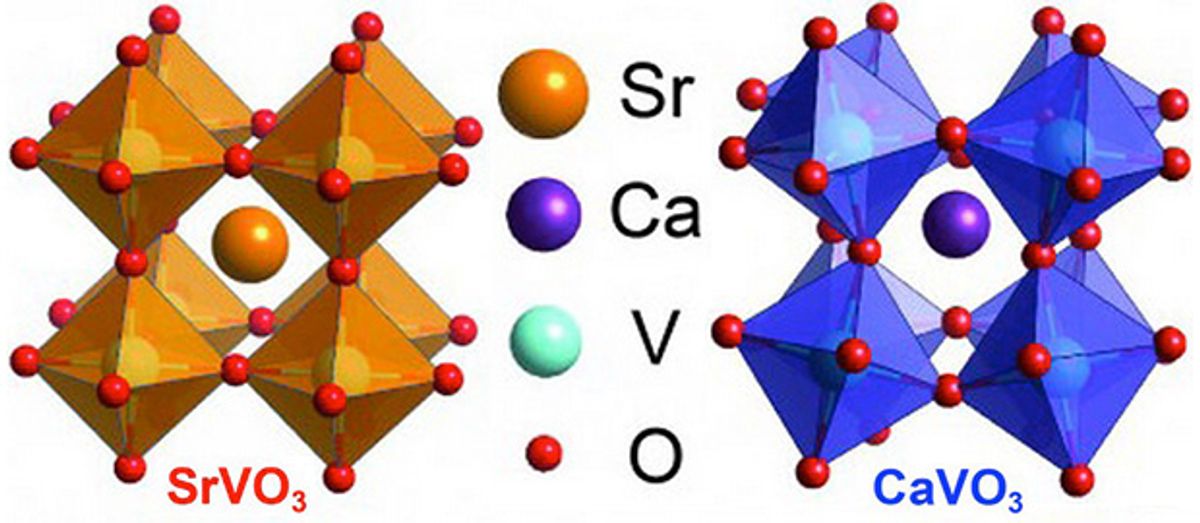

In this new class of materials, which includes strontium vanadate and calcium vanadate, electrons flow like a liquid rather than like a gas as they do in conventional metals. The Penn State researchers wanted to see if they could make these correlated metals demonstrate a high optical transparency despite possessing metal-like conductivity.

“We are trying to make metals transparent by changing the effective mass of their electrons,” said Roman Engel-Herbert, assistant professor at Penn State, in a press release. Engel-Herbert explains that the team has chosen materials in which the electrostatic interaction between electrons is very large compared with their kinetic energy. The result, he says, is that:

Electrons ‘feel’ each other and behave like a liquid rather than a gas of non-interacting particles. This electron liquid is still highly conductive, but when you shine light on it, it becomes less reflective, thus much more transparent.”

Even while they were conducting the correlated metals research—which is explained in a paper published in the journal Nature Materials—Lei Zhang, the paper’s lead of author, knew that the team had struck upon something significant.

“I came from Silicon Valley, where I worked for two years as an engineer before I joined the group,” said Zhang, who is a graduate student in Engel-Herbert’s group. “I was aware that there were many companies trying hard to optimize those ITO materials and looking for other possible replacements, but they had been studied for many decades and there just wasn’t much room for improvement,” said Zhang in the press release. “When we made the electrical measurements on our correlated metals, I knew we had something that looked really good compared to standard ITO.”

With ITO selling for about $750 per kilogram, while vanadium goes for only around $25/kg (and strontium for even less), it’s pretty clear that the correlated metals will make for much cheaper transparent conductors. The question is whether it will be possible to integrate these materials into existing large-scale manufacturing processes for displays.

Engel-Herbert added: “Our correlated metals work really well compared to ITO...From what we understand right now, there is no reason that strontium vanadate could not replace ITO in the same equipment currently used in industry.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.