MIT researchers have made solar panels thinner than human hair that provide 18 times as much power per kilogram as today’s glass and silicon-based solar panels. These solar cells are in fact one-hundredth the weight of conventional photovoltaics.

Should it be possible one day to scale up this technology, the implications could be sizable. Hundreds of thousands of warehouses dot the American landscape. Their large roofs are prime real estate for solar-power installations, but they wouldn’t be able to bear the weight of today’s silicon solar panels, says Vladimir Bulović, a professor of electrical engineering and computer science at MIT. “If we had lighter-weight solar panels, we would be able to get those roofs very quickly electrified.”

We now do, Bulović says. He envisions one day being able to buy a large carpet of solar cells “and simply unroll it on a roof.”

“There’s nothing stopping the scalability of the process.”

—Vladimir Bulović, MIT

The ultrathin solar cells could also be laminated onto boat sails, drone wings, and tents. They could be especially useful for providing power in remote areas and during disaster-relief operations.

The weight of silicon solar panels has kept solar power from being deployed more rapidly than it has so far, Bulović says. Thin-film solar cells, such as the ones made by First Solar, are lighter and also easier and cheaper to make. But they are still deposited on a sheet of glass, so the final modules become just as heavy as conventional ones.

Reducing the weight of solar cells would allow manufacturers to make much larger solar panels and also make installation dramatically cheaper, he says. The few attempts at making superthin solar cells on flexible plastic films so far have yielded very tiny experimental devices—or they’ve been fragile or do not have the best performance for practical use.

The MIT team coated a sheet of plastic with a layer of parylene a few micrometers thick. Parylene is electrically insulating and protects against moisture and chemical corrosion. On top of this, the researchers deposited different solar-cell layers using printable inks made of various materials. The entire solar-cell structure is 2 to 3 micrometers thick. The researchers chose an organic semiconductor for the active light-to-electricity conversion layer, and silver nanowires and a conductive polymer as the transparent electrodes. You could also use perovskites for the light conversion, Bulović says. Those materials would give higher efficiency, but they degrade in moisture and oxygen.

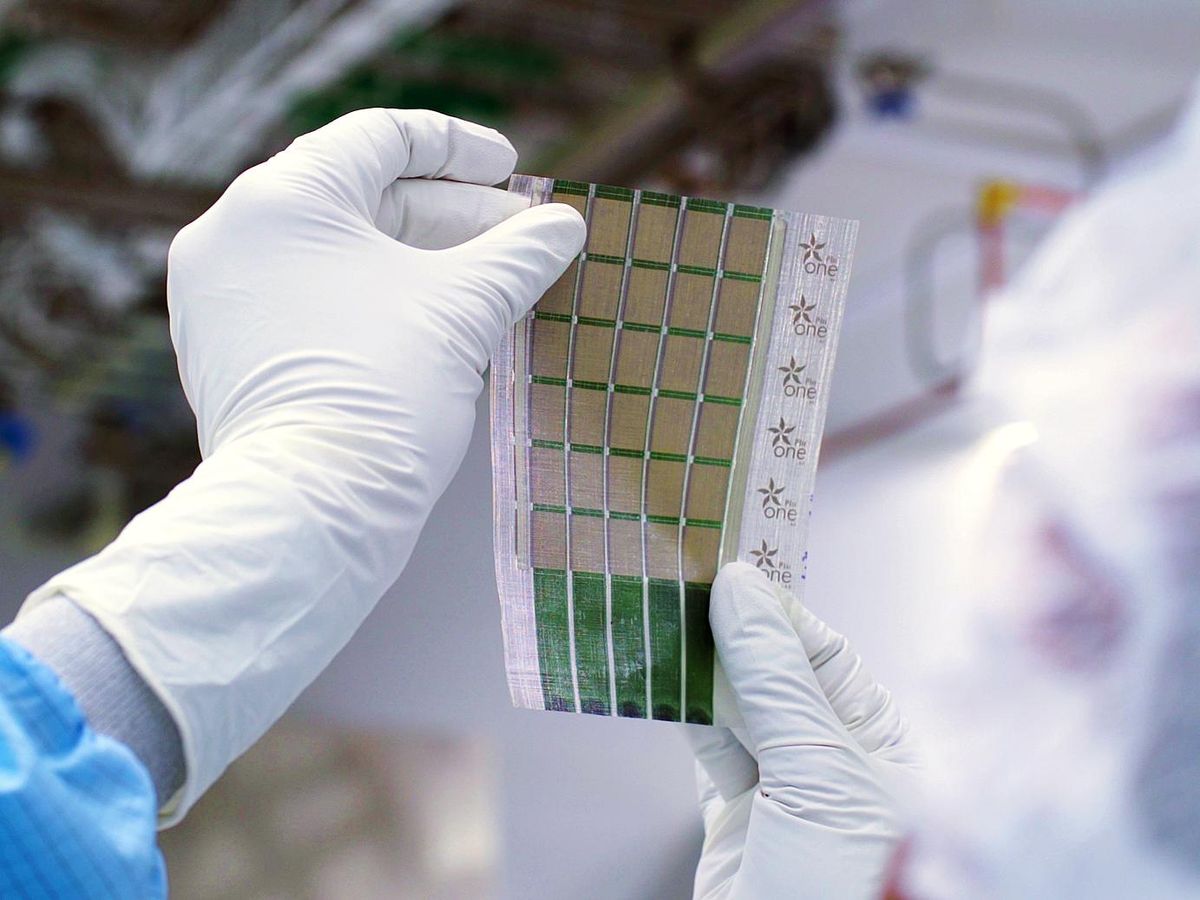

Next, the team put a few micrometers of glue around the edges of the finished solar cells and brought them into contact with a strong, lightweight, commercially available performance fabric. Then they pulled off the fabric, peeling with it the very thin parylene substrate and the solar stack on top of it, which transferred the solar modules to the fabric.

The fabric modules had a power density of 370 watts per kilogram and weighed 0.1 kilogram per square meter. Commercial residential silicon solar panels, by contrast, have a power density of 20 W/kg and weigh 10.7 kg/m2 while cadmium-telluride thin-film solar modules on glass substrates have a specific power of 13 W/kg and weigh 14 kg/m2.

While the laboratory-scale devices Bulović’s team has made are about 10 x 10 centimeters in size, he says that “everything that we’ve demonstrated can be made bigger; there’s nothing stopping the scalability of the process.”

The paper-thin solar cells will need to be stable for use in the real world. The researchers plan to do more extensive testing and to make a lightweight encapsulation layer that can withstand the elements and keep the solar cells safe and working for years. “These cells as they are could last one or two years without packaging,” Bulović says. “With packaging, we could extend that to five to 10 years. And that’s plenty.”

Bulović already has three startups under his belt, including quantum-dot electronics company QD Vision, which was acquired by Samsung, and Ubiquitous Energy, which is making transparent solar cells. He now plans to further develop and commercialize the new ultrathin solar cells through a newly launched startup, Active Surfaces.

The researchers presented their new device in a paper published this month in the journal Small Methods.

- Quantum-Dot Coating Could Pull Solar Energy From Your Windows ›

- Ultrathin Solar Cells for Lightweight and Flexible Applications ›

- 2D Solar Cells Poised to Set Power-Per-Weight Record - IEEE Spectrum ›

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.