The Secret Art Of Chip Graffiti

Chip designers have often etched whimsical imagery onto their creations, but as automated tools improved and design cycles shrank, so did companies’ tolerance for the improvised extras

Mike Davidson knows art when he sees it. But he didn’t expect to see it on a microchip. One day about six years ago, the senior research engineer was quietly working away in his lab at the National High Magnetic Field Laboratory at Florida State University, in Tallahassee, taking photographs for his annual chip-shot calendar, which features microscopic images of microchips. To fit as much of a MIPS R4000 chip as possible into a single photograph, he set his high-powered Nikon FX/L optical microscope at a relatively low magnification, between 25X and 100X. Then, to make the circuitry "pop" for a more richly detailed photo, he lit large areas of the chip with a tungsten-halogen light and increased the magnification to 600X. Suddenly, he saw a face [see photo, above].

To Davidson’s eye, the preternaturally long mug, round spectacles, lumberjack hat, and flyaway hair looked just like Waldo, the then-ubiquitous cartoon character of “Where’s Waldo?” fame. “I realized it wasn’t part of the integrated circuitry,” Davidson said, “but I thought it might be something the engineers had put on the chip to thwart anybody trying to reverse-engineer it.”

Intrigued, he posted photographs of Waldo on his Molecular Expressions Web site, home to microscopic images of everything from beer bottle labels to DNA. Soon after, he was contacted by the image’s creator, chip designer Kevin Kuhn, who worked at MIPS Technologies Inc., Mountain View, Calif.

“He told me it wasn’t really Waldo [but] another designer at MIPS,” Davidson told IEEE Spectrum. “He said it was just artwork that he had put on the chip because he had spent such a lot of his life working on the chip.” Kuhn called it a sort of signature and told Davidson to look for other images on the chip, including a license plate containing the chip number and its version [see photo, above].

What started out as a serendipitous discovery became a passion for Davidson. He began looking for and collecting images he found on other chips and putting them on what he now calls the Silicon Zoo portion of the Molecular Expressions Web site (https://micro.magnet.fsu.edu/creatures/index.html). As word about the site got around, design engineers from all over sent Davidson chips and wafers, hoping to preserve their silicon creatures for posterity. Now the Zoo features the ersatz Waldo along with 300 other pieces of what is variously termed chip art, artifacts, or graffiti.

The images include everything from chip designers’ names, renderings of favorite pets, cartoon characters like Dilbert, and planes, trains, and automobiles. These images are fabricated along with the transistors and interconnects on one or more metal layers overlying a silicon wafer. First, the image is drawn on a mask used to make a pattern in photoresist overlying a metal layer, usually the first. Through the gaps in the mask ultraviolet light is shone onto the photoresist, hardening what it exposes. A solvent washes away the soft remainder, exposing areas of aluminum to etching in their turn. Lastly, the hardened photoresist is washed off with acid, leaving an image in metal.

Many of the creatures housed in the Silicon Zoo Davidson found on small-run video and graphics chips dating from the late 1970s and early 1980s. Back then chip graffiti was more abundant, in part because it thwarted illegal copying, said Louis Scheffer, a former chip designer with Hewlett-Packard Co. and now a fellow at Cadence Design Systems Inc., San Jose, Calif. If someone stole the chip design by simply copying the masks, the graffiti would be copied, too, and give the thief away.

But in 1984, the U.S. Congress passed the Semiconductor Chip Protection Act. Pre-1984, graffiti was the only way to prove copying; the fact that the rest of the mask was identical was not sufficient proof. After 1984, an identical copy of a mask’s working parts was an automatic copyright violation, and graffiti served no useful purpose.

In a sense, then, the Silicon Zoo is more like a museum displaying relics of a bygone era. In contrast, the silicon art gallery (https://www.chipworks.com/art/silicon_art.htm) maintained by Chipworks Inc., a reverse-engineering company based in Ottawa, features graffiti from recent chips. The cartoon character Hagar, for one, who resembles a Viking warrior, was taken from a Nokia cell phone whose die markings date the chip to 1999. According to Julia Elvidge, vice president of marketing and sales, the company’s engineers find such art on 1 in 10 of the chips they reverse-engineer and don’t believe there has been a significant drop-off.

Elvidge agrees that at certain chip-makers graffiti is now harder to pull off. She attributes the trend to the unfortunate destruction of chips by wayward doodles, accidents that soured many companies on extracurricular artifacts. Others believe that chip art has fallen victim to advances in circuit design automation and compressed product cycle times.

“Kilroy Was Here”

What motivates those who create chip art? “Certainly marking your territory the way wolves do is part of the motivation,” said Larry D. Johnson, a one-time MIPS designer who went on to manage the Crusoe chip project for Transmeta Corp., Santa Clara, Calif. “People are saying, ‘Look! I’m here.’”

Announcing your existence with images visible only through a microscope may seem an obscure route to fame. In fact, though, according to several chip graffiti artists, enlarged images are often displayed on the walls of people’s offices and cubicles as portions of huge printed plots of the IC. They are also visible to the designers who work on revisions of the IC, markers of those who blazed the buses first.

Many of the images are insider jokes that only other designers or engineers would get, like puns on the names of chips or their functions. The first one that former HP chip designer Willy McAllister did was a visual pun on the adder logic circuits on an arithmetic chip around 1980. “We did full adders and half adders, little snakes with full tummies and little snakes cut in half—it’s pretty juvenile humor,” he admitted [see sidebar].

McAllister, now manager of the microanalytical technology department in the Life Science Technologies Laboratory at Agilent Laboratories, Palo Alto, Calif., considers his masterpiece to be an image he and his designers created for a memory controller in 1988. Part of an early microprocessor chip set used in the HP-9000 series computers, the controller’s code name was Cheetah. So right from the start, McAllister was on the lookout for an etchable image of the fast cat.

“The best of all the cheetah images that we’d found” was the September 1986 cover of IEEE Computer magazine, he remembered [see photo]. The cheetah was on the run, but the legs were blurred, so McAllister asked his wife, Monica, a graphical artist, to redraw the picture.

Taking her pencil drawing with him to work, he blew it up on a copier to about a third of a meter long and then digitized it, taking turns with his colleagues at hand-tracing it on an electronic tablet connected to the computer. Such a step would have been impossible just two years earlier, when HP designers still used pencil and paper to architect even 100 000-transistor ICs. The cheetah tracing marked the first time McAllister’s team wielded computer tools to render a piece of graffiti [again, see p. 55].

The tools certainly helped. Pencil and straight-edge tools had confined them to drawing only the most primitive images, such as block letters or stick figures. But for their next design, McAllister’s group gave a leopard a three-dimensional aspect by putting parts of the drawing on two layers of the chip. The animal’s outline went on the first metal layer; its spots on the contact layer (which is used to connect two metal layers vertically).

The innovative 3-D style elicited the desired oohs and aahs from colleagues, along with a bit of unwanted attention.

In the 1980s, when the design team had finished with a chip, they would write the chip artwork patterns onto magnetic tape and send it to the photomask shop, a momentous occasion still known as “tape release” or “tape out.” The photomask shop would then fabricate the dozen or more 40-cm2 glass photomasks containing each chip layer image.

Before the mask shop made the glass plates, technicians imported the data from the magnetic tape into a computer to view the chip mask images. They looked for patterns caused by data-processing errors, by bugs in the designer’s output software, or by damage to the magnetic tape. They also scanned for design goofs such as crossed wires or missing connections. A technician inspecting McAllister’s masks overlooked the leopard outline on the metal mask, but noticed the cat’s spots on a seemingly random part of the contact mask and so mistook them for a flaw. She called McAllister, who said, “‘That’s OK, those are leopard spots.’ We lost a day there."

In the process, HP managers were alerted to McAllister’s cartoon, but his manager “just rolled his eyes” and let it go. The lost day was irritating but probably insignificant, according to McAllister. "He was not going to give me a dressing down after all our effort. But this was one of a number of episodes that eventually gave rise to ’the memo’ that requested chip designers to ’just do chips please.’ "

The cease-and-desist order to McAllister was far from unique. Chip graffiti eluded surveillance because it flew under the radar of both upper management and the relatively primitive computer-aided design tools of the early 1980s. Sophisticated design rules check (DRC) software would be developed only later that decade and perfected in the early 1990s. Until then, designers had to manually check the mask designs for errors, spending hours hunched over giant paper plots of the chips. After much editing, the error rate would sink to zero, at which point the tape was released. Even with all that meticulous eyeballing, some errors got through—and so did a lot of graffiti.

As for management’s attitude toward chip art, many tolerated at least some graffiti because of the skill and status of chip designers. “They’re hard to find,” Davidson said. “And if the designers want to do that stuff, the company can’t just fire them wholesale.”

Other companies were, and still are, less indulgent. Davidson has found only two scraps of art on chips from Intel Corp., and the company would not sanction an interview with the engineer responsible for them. For a U.S. chip-maker, Intel is unusual, but its attitude is apparently shared by its Japanese counterparts. Neither Davidson nor the engineers at Chipworks have found a single piece of graffiti on a Japanese-made chip.

European designers, in contrast, seem quite fond of chip art. Graffiti graces devices from both Siemens (now Infineon) and SGS Thompson (now STMicroelectronics) that are now displayed in the Silicon Zoo. According to Chipworks’ Elvidge, Siemens seems particularly tolerant, with many chips featuring several versions of the same muscleman [see photo].

Tools erase graffiti

Management’s disapproval is not the only foe faced by chip art at many companies. “People aren’t doing this as much these days for a couple of reasons,” explained McAllister. “One is that [the evolution of] large design teams spread out the spiritual ownership of the chip among many people, so there was less motivation for the individual artists. The other is we were doing chips that represented important product lines. Over time, we made some mistakes with the little cartoons. Delaying one of these chips might cost a week, and a week became extraordinarily valuable as the criticality of these chips went up.”

Nor have shorter design cycles helped. Engineers don’t have the free time to get artistic, said Bob Weppler, now a senior project engineer at Rockwell Automation, Mayfield Heights, Ohio.

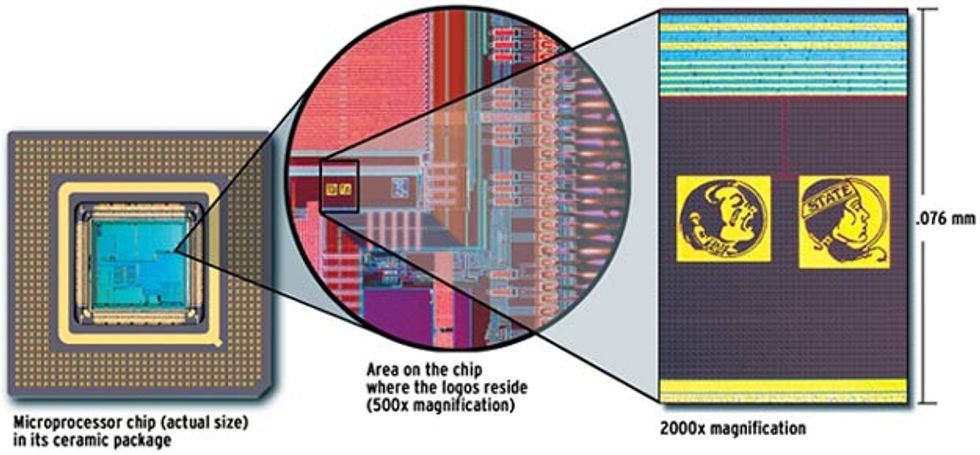

Mike Davidson, whose collection of chip graffiti appears on his Silicon Zoo Web site, starts the hunt for art by removing the protective cover on a packaged chip, here a Silicon Graphics MIPS R12000 microprocessor [actual size, far left]. At 500X magnification, strange artifacts are seen between a large cache and a series of buses. 2000X magnification reveals the Seminole Indian logos of Florida State University.

Click on image for larger view.

Weppler himself has had a hand in several graffiti-filled chips. At Allen-Bradley in 1988, he worked on a node adapter IC with Michael Philippi and others then at Rockwell Semiconductor. The chip features references to Douglas Adams’s novel The Hitchhiker’s Guide to the Galaxy, including the answer to life, the universe, and everything (the number 42); a cricket wicket; and a sperm whale. Now, said Weppler, management’s attitude is: “If you’ve got time to design a sperm whale, why aren’t you off designing something we can sell?” [see photo].

The threat of a fatal design error spurred the development of software tools that could automatically interpret drawings of ICs and search them for errors. DRCs started out as simple checks of chip wiring geometry, such as line width and line spacing. As workstation computers caught up in performance, the software evolved to check for wiring errors, like shorts and opens, by comparing computer-aided design (CAD) layouts against functional schematics of the chip, in the process known as functional checking. At this point, error-checking software started to discover flourishes like McAllister’s leopard spots and one of Philippi’s designs, an ill-fated bowl of petunias. “It couldn’t make it past DRC and [Rockwell] had a policy that even artifacts had to pass DRC,” Weppler said.

“Functional checking or layout-versus-schematic testing finds a lot more graffiti,” Scheffer confirmed. “Even if the graffiti is DRC correct, it does not correspond to anything in the schematic, nor does it follow the usual electrical rules of design. It’s fairly easy to make graffiti that’s DRC correct—making it functionally correct as well is more work than most graffiti artists are willing to take on.”

Another factor contributing to chip art’s decreasing prevalence is that today’s designers are far more removed from the actual mask-manufacturing process than they were during chip graffiti’s heyday. They have gone from the paper and pencil of the 1970s to the stylus and electronic pad of the early 1980s to the polygon editors (so-called because the features drawn were polygonal) of the mid- to late 1980s. Until that point, graffiti artists could freely ply their trade.

Since then, the rule book has been rewritten. Now, chip designers no longer have to plot out lines and spaces for the transistors and interconnections making up each layer of a chip. Standard design elements such as logic cells are sold by application-specific IC (ASIC) vendors and are integrated right into the chips Weppler now creates. Rockwell Automation no longer has to buy updated tools for him to create his own features, though he still has tools to automatically create text artifacts, like the designers’ names or chip number.

Design elements Weppler can’t get off the shelf, he designs in register transfer level (RTL) language, which describes the chip’s clock, data, reset inputs of registers, and the boolean logic that goes between the register stages. These RTL designs are captured in VHSIC (very high-speed IC) hardware design language, or VHDL, where the designer defines the function he wants the chip to perform.

Instead of drawing flip-flops and logic gates by hand, he gets a synthesis tool to automatically convert the equations and definitions that exist in VHDL into logic gates. The gates are automatically placed and routed with another tool. Direct human intervention is not needed. “If we touch the layout at all, it is only to fix errors or add text artifacts like the part number or lists of designers’ names,” said Weppler.

Managers like it that way. “When companies lose money because of this, they turn the screws down on it,” said Johnson. When he became Transmeta’s director of VLSI design, it fell to him to set rules for embellishing Crusoe, the company’s flagship microprocessor, with graffiti. Having been a designer himself, he could sympathize with the engineers’ desire for artistic license, but as a manager, he felt duty bound to be practical. He came up with a compromise solution: let the designers put their initials—and only their initials—on the chip.

“That way all the people can say, ‘I’m there, my mark is on the chip,’ and it’s all much more carefully controlled,” he explained. Despite his best efforts, though, a few outside contractors did manage to carve unauthorized doodles onto Crusoe.

Whatever chip art is going on, it is done the same way as street graffiti—on the sly. Whether they use photolithography or spray paint, tag IC interstices or subway cars, are thwarted by managers and high-tech manufacturing tools or hunted by cops, microchip designers and graffiti writers are not easily discouraged from practicing their craft.

For chip artists, figuring out how to skirt the automated checkers is just part of the challenge. Said McAllister, “If I did another chip, I’d figure out a way to get [a design] in there.”