As soon as the new Dutch government took office in October, it announced an aggressive target—to reduce carbon emissions by 49 percent by 2030. This will ultimately require the Netherlands to sequester 20 million metric tons of carbon dioxide per year—equivalent to the annual emissions produced by 4.5 coal-fired power plants.

Sequestering that much CO2 underground will be difficult, whether it’s captured directly from the flues of power stations and steel mills or extracted from the air. Currently, the Netherlands sequesters less than 10,000 metric tons of CO2 annually.

Gert Jan Kramer, a physicist at Utrecht University, says the government’s aims are “drastic” but possible. “The technology and the industrial capacity for storing underground tens of megatons [1 megaton = 1 million metric tons] of carbon dioxide is ready,” he says.

Underground natural gas reservoirs are already leakproof, and pumping CO2 into them while extracting gas would maintain their internal pressure, which would stabilize underground rock structure and prevent seismic activity. “We have investigated every event and consequence imaginable, and we’ve concluded that underground carbon storage is safe,” says Robert Hack, an engineering geologist at the University of Twente, in the Netherlands.

However, carbon sequestration projects have not fared well in Europe because of public opposition. More than 20 large-scale carbon capture and sequestration projects are now operational worldwide, but only two are based in Europe.

One of Europe’s largest proposed projects, the Rotterdam Capture and Storage Demonstration Project, which was designed to capture, transport, and sequester about one million metric tons of CO2 per year, 20 kilometers offshore, fell through in June when two private investment companies backed out. Storing carbon offshore is usually easier, Hack says, because it’s generally more accepted by the public—but it’s also more expensive.

The Carbon Question

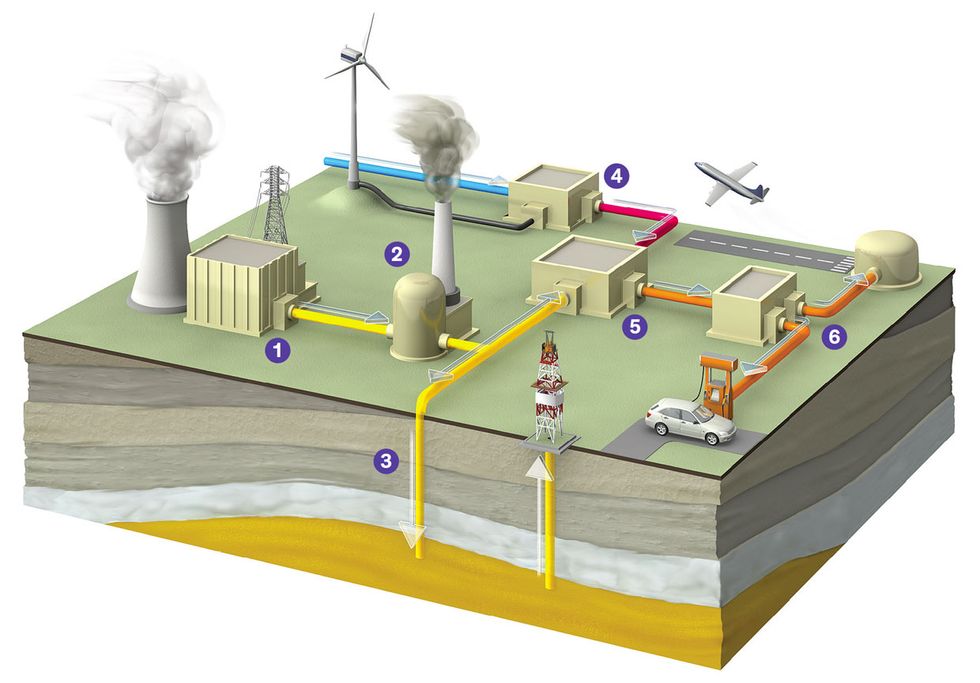

Once carbon is captured, the choice becomes whether to recycle or store it. CO2 is produced from

the burning of fossil fuels to generate electricity [1]. Next, CO2 is scrubbed from the resulting flue

gas [2]. If storage is chosen, the CO2 is then deposited underground in rock layers [3]. To recycle

the carbon instead, electrolysis is applied to water, producing hydrogen [4]. The CO2 undergoes

a reaction with the hydrogen to create methanol [5]. The methanol is used to make hydrocarbon

fuels, including kerosene and gasoline [6].

If the Netherlands’ new policy is to succeed, such facilities will need to be part of the nation’s future. “The Dutch government will have to give a strong signal that they want to scale up the carbon sequestration as a mainstream application—not just a 1-megaton operation but a 10-megaton operation,” says Kramer.

There is another way to deal with carbon dioxide in the atmosphere, and some researchers prefer it to sequestration: If you can’t get rid of CO2, just transform it into something useful, such as synthetic fuel or a new material. “I think there is a strong case for recycling CO2,” says Frans Saris, a physicist and former chairman of the board of management of the Energy Research Center of the Netherlands.

It’s possible to produce several types of synthetic fuel from CO2. One way to do this is to apply electrolysis to a mixture of water and CO2. The mixture splits into carbon monoxide (CO) and oxygen. Next, a reaction between CO and hydrogen produces methanol (CH3OH).

Another way is to mix CO2 directly with hydrogen (which is also produced through the electrolysis of water) at high temperatures to form methanol [see graphic]. This methanol can then be used as a fuel for combustion engines or fuel cells, or as the starting material for hydrocarbon fuels, including kerosene and gasoline.

As an example, Saris points to a Tata Steel facility near Amsterdam. “We have calculated that the amount of CO2 that is emitted by the steel mill, if converted to kerosene, would power at least half of the planes flying from Schiphol Airport,” he says.

However, other scientists disagree with the idea that recycling CO2 to produce synthetic fuels can meaningfully reduce the amount of carbon in the atmosphere. One problem is that the same process that scrubs CO2 from the flue gases of a fossil-fuel power plant also reduces the plant’s electrical power output by up to 25 percent, says Hack. This is because that process requires a substantial amount of energy to heat, cool, and pump solvents that absorb CO2 from the flue gases.

Gunnar Luderer, a researcher at the Potsdam Institute for Climate Impact Research, in Germany, argues that synthetic fuel produced from CO2 for transportation is not really carbon neutral when captured from the flues of power plants. “You cannot have a second carbon capture from the emissions of a car or an airplane. In the end, it is fossil carbon that undergoes combustion twice,” he says.

Luderer agrees, however, that capturing carbon from the air and using it for purposes other than transportation changes the equation. Cement factories are known for their massive release of carbon into the atmosphere. Instead of capturing that carbon after the fact, it would make more sense to extract carbon from the air and use it to produce carbon fibers. These fibers are less corrosive than steel beams and require less concrete to cover. Using them in place of steel could reduce demand for concrete, and thereby cut emissions from its production. “Here, you would have a double benefit,” says Luderer.

A version of this article appears in the January 2018 print magazine as “The Netherlands’ Carbon Dilemma: Sequester or Recycle?”