THE INSTITUTEAfter months of building a high-performance hybrid vehicle, a 5,138-kilometer drive across North America, and four days of competition, the University of Victoria’s Formula Hybrid team took first place at the annual IEEE/Society of Automotive Engineers competitionfor best overall hybrid design.

The contest, which was held this year from 28 April to 2 May, challenges undergraduates to design and build a race car with a hybrid drivetrain. The event has been hosted by Dartmouth College at the New Hampshire Motor Speedway since 2006. This year teams from 20 different schools participated. The vehicles were tested on their acceleration, endurance, maneuverability, and overall design.

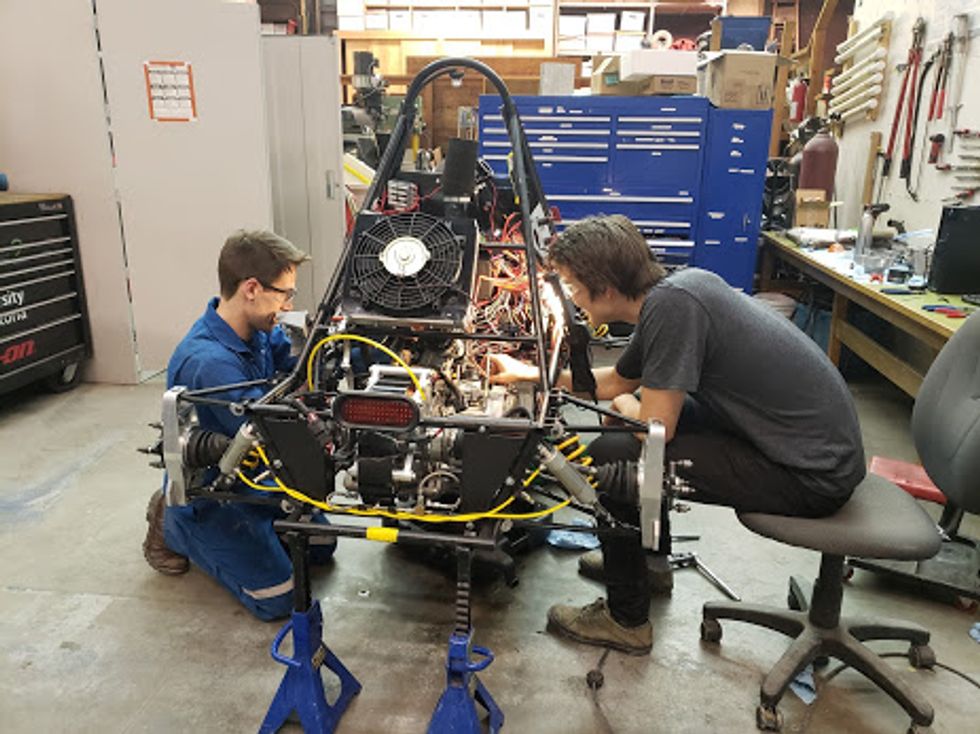

Like their competitors, the winning Victoria team, from British Columbia, Canada, used electric power as well as gasoline. What set the Victoria group apart was the use of a capacitor-based system for energy storage rather than lithium-ion batteries. That allowed them to discharge energy at a faster rate, says IEEE Student Member Jules Pare, part of the Victoria team. He headed up the group working on the car’s chassis and suspension.

“The capacitor system is lighter than an equivalent lithium-ion battery pack for how much potential energy the system can deliver,” Pare says. The design choice wasn’t without drawbacks, he notes: “The capacitor system doesn’t have as much energy or capacity, so the car doesn’t get as long of a run. But it can deliver way more instant power for less weight.” And in a competition where speed is vital, weight is an important factor during the design process, the team says.

The group used regenerative braking to charge the capacitor system. “There are a lot of hills on the course,” says Tylynn Haddow, also an IEEE student member and the team’s electrical lead. When the car goes downhill, the capacitor system allows for the buildup of energy to be used going up and the same for going in and out of turns, she says.

Among other distinctions, the team received recognition for its innovative use of pneumatic antiroll technology to keep the vehicle steady during sharp turns. The team’s interim power train lead, Cayenne Chen, says the device employs dual-action pneumatic pistons that are linked across the car. Using pressurized air across the vehicle helps maintain traction while turning corners and allows for better bump absorption, Chen says.

“The use of pneumatic antiroll also allowed us to adjust the pressure of the air, he says, “and therefore, the balance of the car, really quickly.”

The car’s suspension affects how well it can grip the road. “The lighter it is, the faster the car will go,” Pare says, “and the stiffer it is, the better it resists twisting.” The design played a large role during the race’s autocross portion, which required a lot of sharp cornering, he says.

TEAM EXPERIENCE

Members of the team say they joined the UVic Formula Hybrid club because they were interested in getting hands-on experience building a hybrid vehicle. Participation in the club enabled them to challenge themselves, learn from their mistakes, and collaborate with their classmates. “In the real world, and in class, it’s stressful to get things correct the first time,” Pare says. “This is a great way to learn about different roles and responsibilities that you’ll encounter in your career.”

A number of the students say they felt they’ve contributed to improving society. They believe the future is bright for hybrid technology, they say, despite hesitation among consumers who are unfamiliar with such cars’ abilities.

“Even though hybrid vehicles are more complex because they have two systems, it actually takes a lot of the strain off of the individual power systems, allowing each of them to last longer and requiring less maintenance,” Haddow says.

Any step made to reduce emissions is beneficial, Chen says: “The cars are coming down in cost, are more fuel efficient, and reduce carbon dioxide emissions.”

The team is building a new vehicle, which is intended to be used in future races. According to Pare, the team plans to switch from the capacitor to a lithium-ion-based accumulator, a rechargeable battery used for moderate and short-term tasks.

The current vehicle frame has been in use since 2016, and the team intends to start from scratch with that in an attempt to reduce its size and weight and gain more creative control of its overall design. They intend to have both vehicles functioning in parallel, Pare says, to serve as teaching and testing tools for future team members.

“Team members interested in hands-on learning or testing could work on the current car,” Chen says, “while members who are more interested in design can work on building the new one.”

“We’ve got quite a year ahead of us,” Pare says. “This is going to be the first time in a while that we’ve done a new power train and completely different setup, so it’s going to be a huge season for us.”