THE INSTITUTE In 2013 Ph.D. candidate Kim L. Sorensen and his advisor, IEEE Senior Member Tor Arne Johansen, talked with U.S. Coast Guard representatives about a relatively new challenge for the military: the buildup of ice on drones and other unmanned aerial vehicles. UAVs weren’t outfitted with protection to eliminate ice buildup.

Sorensen, tasked with finding a solution, determined that using electrothermal technology and algorithms to autonomously detect and remove ice from UAVs while in flight was the best approach. That became the focus of his Ph.D. project.

At the time, he was pursuing a doctorate at the Norwegian University of Science and Technology’s Center for Autonomous Marine Operations and Systems, in Trondheim.

Johansen, then and now a principal researcher at the center, is director of its UAV laboratory and a well-respected professor.

From that meeting, Sorensen says, interest in his work picked up. In 2014 he went to NASA’s Ames Research Center as a visiting researcher to continue his work. Sorensen built the first prototype of his system there with the help of the center’s scientists. The prototype was tested in 2015 on board a UAV that flew out of the Joint Base Elmendorf-Richardson, a U.S. Air Force facility in Anchorage.

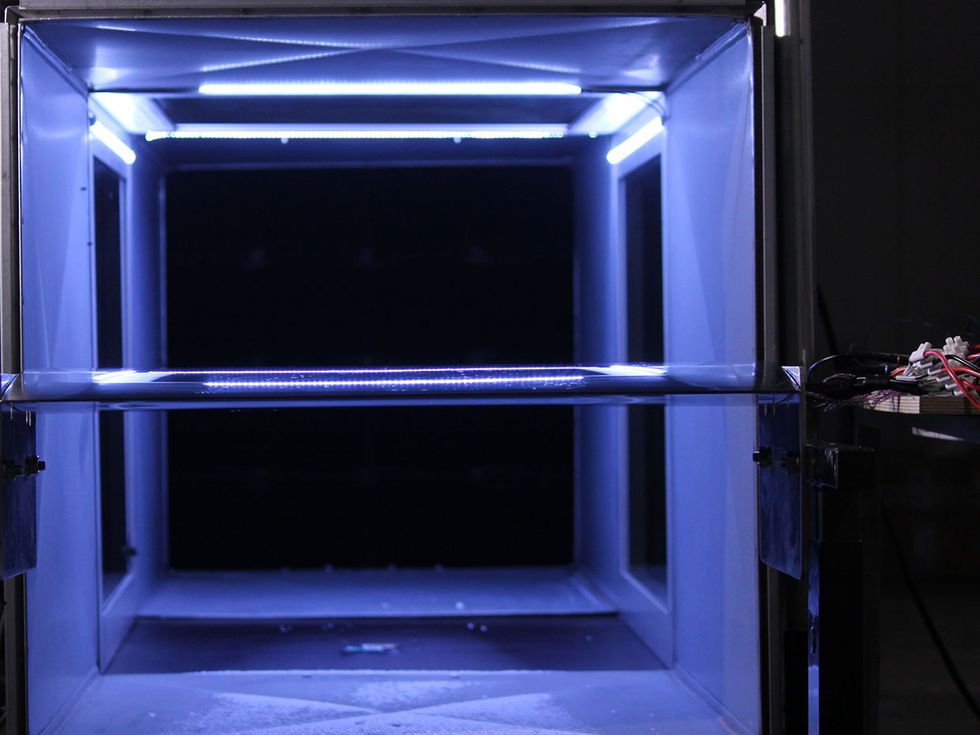

Since then, Sorensen says, the technology has been tested regularly in wind tunnels and on board UAV flights.

In 2017 Johansen, Sorensen, Sorensen’s Ph.D. classmate Kasper T. Borup and the university’s technology transfer office founded UBIQ Aerospace in Trondheim to commercialize the technology, which is now called D•ICE.

Borup specialized in automation and robotics at the university, and his research interests include nonlinear control systems and their applications to UAVs.

Sorensen is the startup’s CEO, Borup is its CTO, and Johansen is a technical advisor and a member of UBIQ’s board of directors.

The company delivered its electrothermal panel for wings to its first customer last month.

HAZARDOUS CONDITIONS

Sorensen says ice tends to build up on aircraft on the leading edge of the wings and stabilizers, propellers, and sensors.

Icing “has been identified as one of the most hazardous weather phenomena for manned aircraft,” Sorensen says. Frozen water on wings increases their weight—which reduces lift and can cause an aircraft to stall. Ice on a propeller can increase drag and reduce thrust. And sensors can lock up, interfering with the autopilot’s ability to gauge speed and altitude.

Airplanes use various methods to de-ice. Inflatable boots can be attached to the wings and the stabilizers. When ice accumulates on the boots, they can be inflated to break it up. Continuous or intermittent electrical heat is used on propellers, sensors, and other components.

With UAVs, just as with larger aircraft, the accumulation of ice during flight on the wings, propellers, and tail can make it hazardous to fly and even cause them to crash.

EMERGING RESEARCH FIELD

Icing on UAVs is a relatively new field of research with “unknown parameters,” Sorensen says. He researched several solutions for his Ph.D. project and ultimately settled on an autonomous electrothermal system, which can be lighter than mechanical and chemical de-icing systems.

The electrothermal panels can be embedded in the wing of a UAV during the manufacturing process or attached to existing wings, Sorensen says. The panels are activated when the system detects deviations from the expected aerodynamics of the UAV, indicating that ice is forming on the wings.

D•ICE uses two algorithms for icing detection. One is based on the thermal response of the heating zones; the other involves an aerodynamic approach in which the system estimates relevant parameters such as lift and drag and infers whether they have degraded due to icing.

The company filed for a U.S. patent on the technology.

An earlier version of D•ICE is described in a paper published in the IEEE Xplore Digital Library.

MORE FEATURES

To start, the company is focusing on the leading edge of wings, Sorensen says. But the team aims to use its technology on other unmanned aircraft parts.

The team also is writing detection and control algorithms to allow the system to allocate the appropriate amount of energy, Borup says.

UBIQ also is working on a unit to control the energy supplied to the thermal panels. “That allows us to de-ice in a smart way, so that we’re not blowing through energy at an incredible rate,” Borup says. “We need to be smart about how energy is used onboard an unmanned aircraft, because of its short flight time.”

RESEARCH SPINOFF

Because the D•ICE idea resulted from research conducted at the university, the founders went through a technology transfer process, which gave the university part ownership of the company as well as royalties from sales.

UBIQ has received funding from a number of sources including the Research Council of Norway. Borup expects UBIQ to be ready for its Series A seed round in 2022.

“We’re convinced that UBIQ is going to be a big success,” Sorenson says. “Fundraising should get easier once customers report that the D•ICE solution is solving their icing problems and providing them with operational predictability.”

This article appears in the June 2020 print issue as “Startup Sets Drones on Defrost.”

Kathy Pretz is editor in chief for The Institute, which covers all aspects of IEEE, its members, and the technology they're involved in. She has a bachelor's degree in applied communication from Rider University, in Lawrenceville, N.J., and holds a master's degree in corporate and public communication from Monmouth University, in West Long Branch, N.J.