Covid-19 spreads via droplets expelled from an infected person’s lungs, so determining how the release of moisture is affected by different masks is an important step towards better protective gear. Now, using a new technique in 3D printing, University of Cambridge researchers have created tiny, freestanding, conducting fibers they claim can detect respiratory moisture more effectively than anything currently on the market.

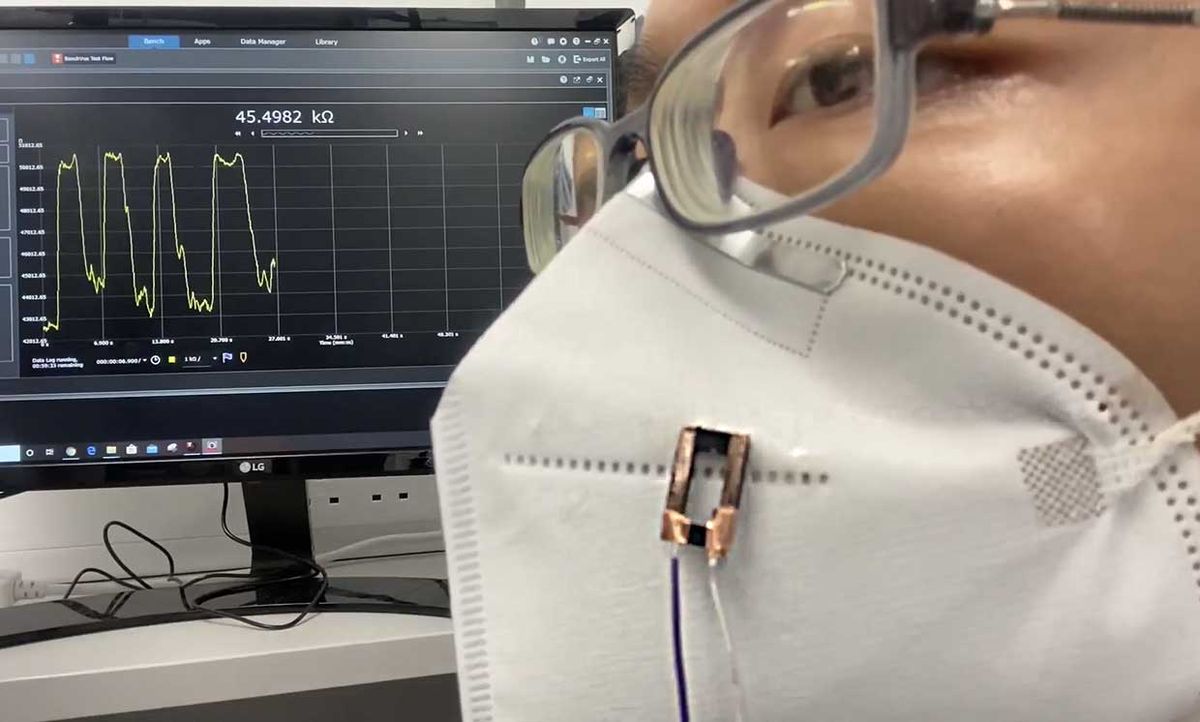

The researchers demonstrated the fiber sensors by testing the amount of breath moisture that leaks through face coverings. They attached their fiber array to the outside of the mask, wired it to a computer, and found that it outperformed conventional planer chip-based commercial sensors, particularly when monitoring rapid breathing. (A paper describing the invention was published today in the journal Science Advances.)

Dubbed “inflight fiber printing,” the technique enables the researchers to print the fibers and hook them into a monitoring circuit, all in one step.

“Previously you could have very small conducting fiber production but it could not be incorporated directly into a circuit,” says Shery Huang, a lecturer in bioengineering at the University of Cambridge who led the research. “The main innovation here is we can directly incorporate these small conducting fibers onto the circuit with designable fiber pattern structures,” she says.

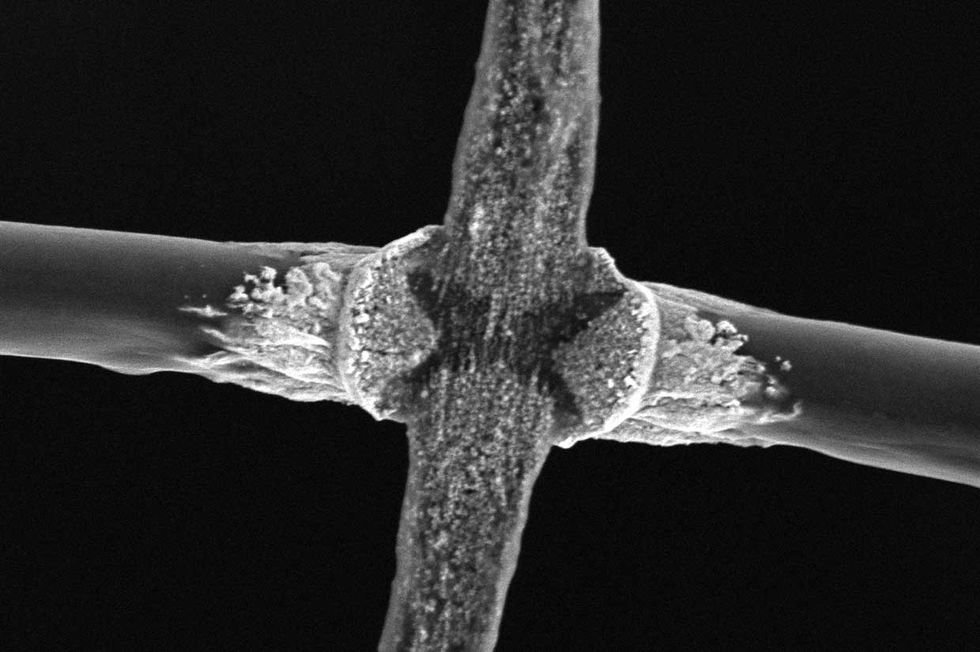

The researchers were able to overcome the challenges associated with bonding and connecting the fibers into a circuit using a combination of techniques. First, they designed the fiber as a composite structure, with a core made of conducting materials and wrapped by a protective sheath. Second, they optimized the printer system to increase the level of control over how the contacts form and how the fibers are printed.

The conducting fibers measure less than three micrometers in diameter and can be fabricated while suspended in the air or on a surface, without any additional processing. The fabrication can be done in ambient atmospheres with mild heating. And the result is a sensor that’s much faster to respond to changes.

“It takes a long time for the moisture from breath to dissipate from commercial sensors,” says co-researcher and PhD student Andy Wang. This reduces their ability to accurately capture the rise and fall of rapid breathing. “Our fiber is extremely thin and suspended in the air, with high surface area-to-volume ratio, so it allows our exhaust moisture from breath to attach and also dissipate very quickly,” he says.

In their demonstration, the researchers found that respiratory moisture and droplets tended to leak out of fabric masks through the front, while N95 masks tended to leak around the edges of the mask, the researchers found. This kind of knowledge may be useful in informing or designing face coverings for use during the pandemic or in hospitals.

Aside from the immediate application to developing better personal protective equipment to combat Covid-19, Huang says she would like to develop the fibers for use in sports applications, to help monitor the breathing rates and performance of athletes. Such tests are typically conducted indirectly, by measuring oxygen rate in blood, or by having the athlete wear a mask over the face, Huang says. The fiber-based sensors could be placed on a pair of eye glasses and get a more accurate reading than these conventional methods, she says. “It’s a portable, highly sensitive way of measuring respiratory rate,” she says.

She also plans to apply it to multimodal sensing fibers, which will allow multiple biological markers to be monitored simultaneously.

Emily Waltz is a features editor at Spectrum covering power and energy. Prior to joining the staff in January 2024, Emily spent 18 years as a freelance journalist covering biotechnology, primarily for the Nature research journals and Spectrum. Her work has also appeared in Scientific American, Discover, Outside, and the New York Times. Emily has a master's degree from Columbia University Graduate School of Journalism and an undergraduate degree from Vanderbilt University. With every word she writes, Emily strives to say something true and useful. She posts on Twitter/X @EmWaltz and her portfolio can be found on her website.