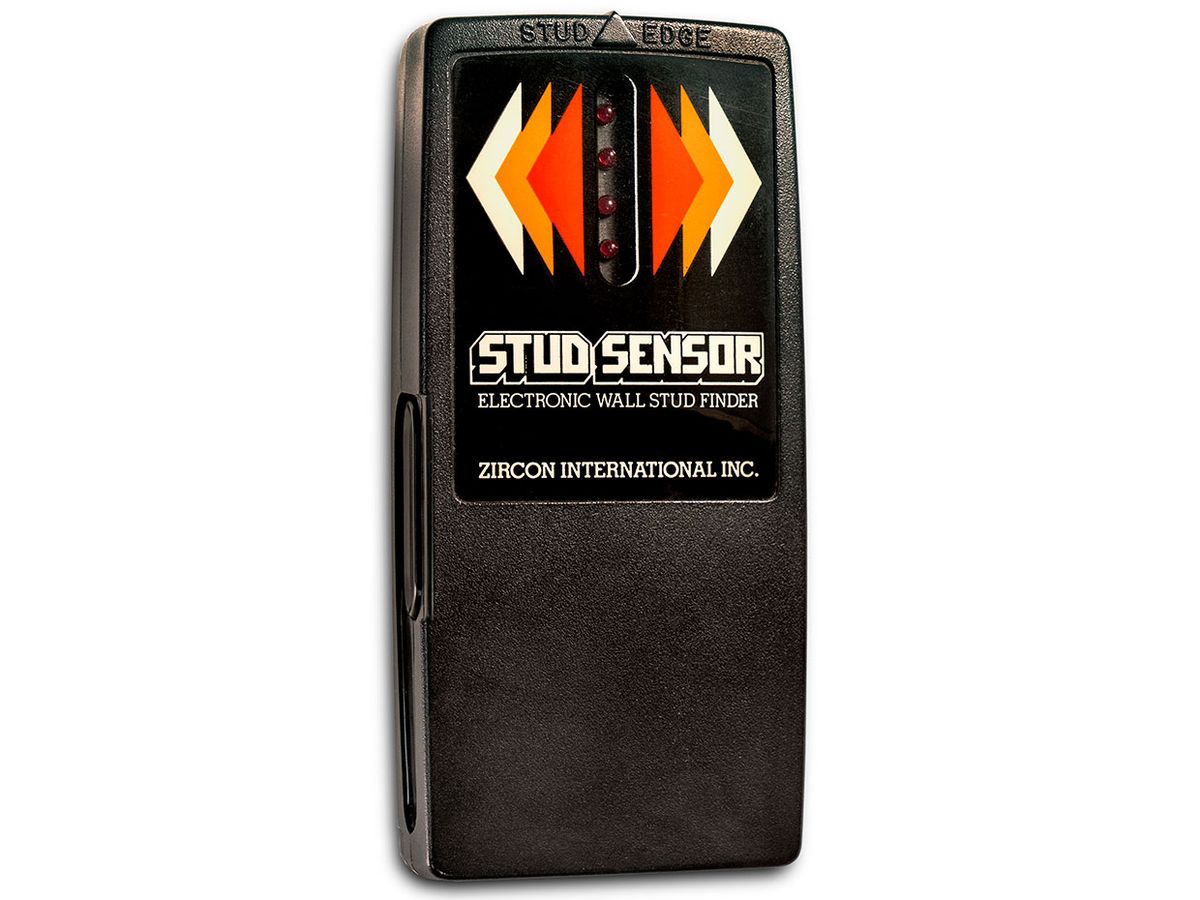

The Consumer Electronics Hall of Fame: Zircon StudSensor

When the inventor of an electronic stud sensor showed his prototype to some big tool companies, not one of them was interested

Humans use tools. It’s what sets us apart from all the animals (except for dolphins, crows, ravens, Egyptian vultures, most primates, polar bears, elephants, sea otters, some mongooses, octopuses and a few rodents). For most of human history, hand tools were entirely mechanical. Electric hand tools began to become popular in the 1930s. It took another half century for the first electronic hand tool to arrive: the StudSensor from Zircon Corp., which was introduced in 1980. With the StudSensor, Zircon single-handedly opened an entirely new market segment to the electronics industry: the hardware business.

It was in the 1860s when people first began building frame houses using standard-size wooden boards called studs. Those framing studs hold up walls, which of course enclose the studs. Originally, the walls were typically plaster over lath, and now they’re usually drywall. To attach anything heavy to a wall, such as cabinetry or a shelf, it’s generally a bad idea to mount it right on the wall. Better to go through the wall and mount the heavy objects on the rigid wooden studs. For as long as there have been studs, however, the problem has been locating exactly where the heck they are behind the walls.

The first stud finders seem to have been introduced around the turn of the 20th century. They were magnets on pivots. Users would run the device across a wall, watching closely to see if the magnet was attracted to something, which would be one or more nailheads in a stud. A great deal of patience was required, but in the end it was usually possible to determine the exact location of a stud hidden in a wall.

Jump forward to the swingin’ ’70s. Robert Franklin, an engineer with Beckman Instruments (now part of Beckman Coulter), in Silicon Valley, would tinker away on side projects in his spare time. He was convinced he could build a better stud finder, and he set out to do it in true Silicon Valley fashion: in his garage. He was doing this at the same time and only a few miles away from where Steve Jobs and Steve Wozniak were working on a garage project of their own.

Franklin received a patent for his stud finder in 1977. The patent describes using a sensor with a capacitor plate to detect changes in the dielectric constant of a wall; basically, any change in charge on the capacitor indicates the presence of a stud. The device would note the center of the change in dielectric constant in a range. If the builder had been conscientious enough to hammer the nails into the center of the stud, the center of that range indicated the center of the stud.

Franklin arranged meetings with several of the big tool companies (most of which are still in business) to sell his stud finder. Not one was interested. He went home and put his prototype on a shelf.

A few years later Franklin was out socializing when he got into a conversation with a stranger. The fellow’s name was Chuck Stauss, and as they chatted they discovered they were neighbors. Turned out Stauss ran a consumer electronics company called Zircon. Product cycles in consumer electronics are short, so Stauss was always looking for the next new thing. Franklin mentioned his stud finder. Soon after meeting, the two were in business together.

It took them a while to get the StudSensor right. The basic concept was simple, but contemporary technology was only barely up to the task. It was “tricky” to build, recalls John Stauss, the current CEO of Zircon and the son of Chuck Stauss.

The capacitive sensor had to react to “infinitesimal changes in voltage and current,” the younger Stauss recalls. “We used discrete components—off-the-shelf parts—and some of them were stretched to the limits of their capabilities. Some ICs would work, while other manufacturers with [ICs that had] identical specs wouldn’t work because the tolerances were different. So the manufacturing issues became very, very critical for us early on, which was also why, in those early days, we began to manufacture it ourselves—so we could control the quality.”

On the plus side, that maddening inconsistency made it nearly impossible for other companies to knock off the design simply by taking the StudSensor’s circuit board and trying to match it part for part.

Zircon introduced the StudSensor in 1980. Sales began briskly, thanks to an existing business relationship Zircon had—it was already providing computer games to Sears. Sears’s Craftsman line of tools was then the most popular in the United States, and after Sears agreed to stock the StudSensor, sales took off.

The next trick was to get it placed on shelves at hardware stores. It was terra incognita—at the time there wasn’t a single electronic tool in the hardware universe. In 1982, the hardware market in the United States was still made up of a few regional companies and a lot of local chains and countless thousands of mom and pop stores.

By then the younger Stauss was on the payroll and making sales calls. “I remember talking to this classic Chicago buyer, sitting behind this desk, chomping a cigar—literally chomping a cigar. He looked at the StudSensor and said, ‘It’s a toy. It’s a fad. It will be over in six months. Why should I buy it?’ I told him Sears is selling out of it. He said, ‘Oh, yeah? Let me take a look at that again.’

“We sold it to every hardware store in the country,” Stauss claims. “When we got into the hardware channel, it was a dream come true. Product life cycles were measured in decades. Our customers had all been around for 100 years, and they paid their bills like clockwork. We were the only truly electronic innovators in this playing field.”

You might figure that once you’ve got a stud finder, you wouldn’t need another. But Zircon, which takes pride in its engineering, kept improving the technology. For example, it eventually upgraded to a custom, mixed-mode analog/digital IC. “That was very tricky then, and it’s still tricky,” Stauss explains. That kept copycats at bay too. Franklin’s patents ran out in 1998, but Zircon continues to innovate, has introduced other products for the builders market, and is still one of the market leaders in an increasingly crowded field. Today, electronic stud finders have taken their place alongside hammers, screwdrivers, pliers, and rulers on just about every handyman’s list of must-have tools.