Advancements in enabling connected cars are astonishing. From the time the first Model T rolled off the factory floor, cars’ functionality has been largely unchanged. When advances did happen, they were mostly mechanical: a bigger engine, more efficient transmissions, safer brakes, and more.

Today, we are witnessing a radical reimagining of the automobile. Advances in connectivity are creating opportunities in the automotive industry. Dashboard navigation, infotainment systems, and Bluetooth-enabled dashboards are a glimmer of what is coming in the not-so- distant future.

In 2015, McKinsey estimated that the number of networked cars would rise by 30% a year1. By 2018, automobiles with connected capabilities were almost 39% of the US market2. By 2020, Gartner estimates that 250 million connected vehicles will be on the roadways, “making [them] a major element of the Internet of Things”3. By 2022, the market penetration is expected to reach over 80%4. Much of this growth will start in premium cars and then the technology will filter down into the value segment.

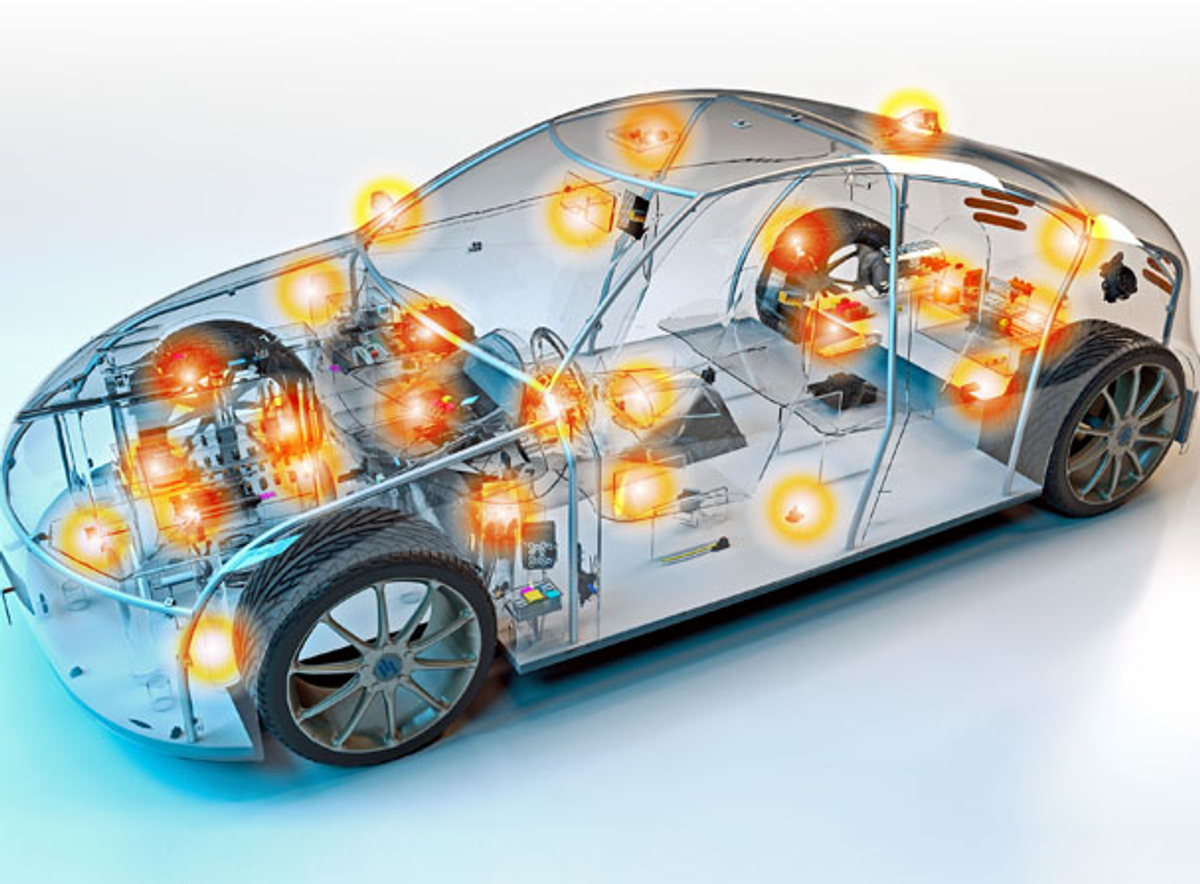

Cloud connectivity, antennas capable of sharing data with many nodes both inside and outside the vehicle, sensors that create a safer and more informed driving experience and rugged, high-speed, in-vehicle data networks are all vital to achieving the seamless, connected, feature-rich automotive future consumers are demanding. TE Connectivity’s (TE) deep understanding of rigorous automotive standards as well as our unparalleled expertise in sensors, data networks, interconnects, and antenna technology can help accelerate success for carmakers in this burgeoning market.

One thing to keep in mind is that while all automobiles share much of the same technology, connected cars and autonomous cars are different topics. Connectivity is turning the car into smart devices with the potential to become crucial pieces in enabling the Internet of Things (IoT). Autonomy means cars gain the capacity to gather input for independent decision-making so that they can be self-reliant.

SENSORS: THE NERVOUS SYSTEM OF THE CONNECTED CAR

Since the late 1970s, electronically controlled sensors have been integral to automotive engineering due to emissions regulations from the United States Environmental Protection Administration (EPA) that required the use of catalytic converters5. This regulation drove the demand for sensors and helped create performance, safety, and comfort advantages. Car owners now expect advanced driver assistance systems (ADAS), adaptive cruise control (ACC), lane departure warning (LDW), traffic sign recognition (TSR), blind spot monitoring (BSM), and intelligent high-beam assistants with light ranging (ILB). Increasingly car owners want telematic modules and other units, such as those used for toll collecting and real time traffic reporting, or rain sensors that gathered weather information.

By 2020, new model cars will have upwards of 200 sensors measuring data within the car and around its immediate environment6. It’s estimated that these cars will be generating 4 terabytes of data per car per day.7

Sensing the World

For the connected car to reach its full potential, a key requirement will be the ability to capture correct and complete data about the surrounding environment. This starts with sophisticated sensor technology that determines a vehicle’s immediate environment. The technology that will prove critical in collecting this data includes high-resolution mono and stereo cameras, radar, and sensors capable of pinpointing objects up to 120 meters away—within one centimeter.

When transmitted by advanced Dedicated Short Range Communications (DSRC) antennas, sensor- generated data enables vehicle-to-everything (V2X) communication, which includes vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communications.

When vehicle systems relay sensor-generated data, drivers can receive alerts about road conditions and driving hazards, such as congested roads, highway debris, or potholes—all well in advance of encountering these problems. When vehicle systems are connected to the roadway infrastructure, sensor generated data can supply accurate, real-time traffic data allowing mapping programs to plot the most efficient route, so drivers save time and greenhouse gas emissions are minimized.

“A lot of the sensors business is driven by what’s happening in electronics. So you see a lot of miniaturization, lower power. When you’re talking about a car, you’re talking about what’s going on inside of a cabin, what’s going on inside the engine. Or even what’s going on outside of a car.”

Byron Hill, VP, CTO, TE Sensor Solutions

Sensing Performance

Equally important will be internal sensing technology. TE offers a wide range of sensors for automotive applications including those that measure everything from position, speed, and humidity (in-cabin, engine air intake) to pressure (brake HPS, urea) and temperature. For example, humidity sensors are designed to improve performance, reduce energy consumption, and increase safety in environments where temperature affects performance. Our fluid property sensors bring real-time fluid monitoring to engines, fuel systems, selective catalytic reduction (SCR) systems, compressors, transmissions, gearboxes, and many other applications. Sensors within the engine, transmission, and braking systems will open the door to an era of predictive maintenance, where vehicles can schedule a visit to the mechanic before an issue arises.

Sensing Wellness

Biometric sensor technology will be another, increasingly important area for innovation. Soon, face, ocular, voice, or ECG technology will enable cars to recognize their driver. Rather than using a key or pressing a keyless start button, the driver will simply grab the steering wheel and embedded biometric sensors will start the car. Piezo sensors embedded in the car seat will monitor heart rate while dashboard cameras will track head movements to see if a driver is getting drowsy. Expertise in both medical device technology and consumer wellness applications—including health and fitness monitors—gives TE an advantage in developing and ruggedizing the miniature sensors that will make driver (and passenger) health monitoring an essential part of the connected driving experience.

ANTENNAS: THE HEART OF CONNECTIVITY

In all of the discussions about car connectivity, the antenna might be the component that’s taken for granted the most. But it’s a key component, along with sensors and in-vehicle data networks, of the connected car.

Typically, in the 1980s, cars had only one antenna: the AM/ FM whip antenna. With the introduction of GPS and cellular service, the number of antennas in cars increased. By the late 1980s, some cars in the US also had another antenna for 800MHz cellular band. With the advent of CDMA, PCS, and GSM in the 1990s, car designers were challenged with finding a way to mount all of the antennas needed to support the multiple bands required for cellular services. Today, there are in excess of 20 antennas in a typical car. There are antennas for 3G, 4G, and 4G LTE cellular service. There are Bluetooth antennas, satellite antennas for GPS, antennas in your tire for monitoring tire pressure, and antennas for on-board infotainment applications. Finding space to fit these antennas into a vehicle is an on-going design challenge.

DSRC Antennas

Soon, cars will feature even more antennas. They may have six antennas just for cellular service. To create robust V2V and V2I communications, cars could require up to six DSRC antennas to provide adequate redundancy and increase coverage. As cars come to rely more on the cloud, redundant long-range antennas will gain even more importance to help ensure constant connectivity and fail- safe reliability.

The Emergence of 5G

The exponential increase in data from sensors and the need for almost-instant insight has made latency a central issue. One of the limitations of current 4G technologies is that radio waves go from the car to the cell tower down to a base station on the ground below it, slowing the speed of transmission. 5G resolves this, providing data rates 30 to 50 times higher than 4G—with a much lower latency.

Instead of having a separate radio transmitter and antenna mounted on a tower, 5G networks integrate both in a single unit called an Active Antenna System (AAS). Each AAS will include up to 128 separate antennas with high-speed coaxial connectors between them and the radio.

When combined with massive multiple-input, multiple- output (MIMO) protocols, these units will enable vehicles to share and receive more than one radio signal simultaneously over the same radio channel. This will mean that the AAS will be asked to handle a content explosion.

When available, 5G networks will operate at speeds 100 times faster than 4G. 5G will handle 100 to 1000 times more machine-to-machine connections than 4G. Latency of less than 1 millisecond is significantly better than 4G. This will make real-time data streaming possible—both to and from the cloud—with streaming infotainment systems, in-vehicle VR systems, and many other applications including vehicle software updates.

Because of an incipient backup system of low earth orbit satellites with very low latency, 5G will encourage innovations around satellite antennas.

“Some of the techniques that we’re using today were only available to real high-end military applications 20 years ago. With 5G, what used to be a dumb passive antenna becomes a very sophisticated active antenna with high-speed connections inside it.”

Bruce Bishop, TE Fellow, Data & Devices

Challenges for Antennas

As antennas become more sophisticated, they must also provide long-term reliability in some of the harshest conditions. This means making antennas capable of withstanding temperatures as high as 185 degrees Fahrenheit (85o C), but not become brittle in subzero weather. Overall, road vibration, engine noise, and speed cannot impact performance.8

Also, as the number of antennas increase, and car manufacturers seek to reduce the amount of cabling and cut down on the complexity of installation, automakers are facing a significant design challenge: the size, location, and shielding of each antenna. Bringing antennas inside the car has required the miniaturization of antennas. It has also required a reduction in electromagnetic and radio frequency interference, which creates an opportunity for innovative design elements. To shield sensitive components from the noise caused by the increase in wireless energy from multiple antennas, TE has developed products with board level shielding (BLS).

Antenna Capabilities at TE

For several decades, TE has designed and manufactured some of the most innovative antennas solutions for consumer products. Our experience enables us to develop and build antennas suitable for the demands of today’s highly connected automobiles. We have developed and manufacture, antennas essential to On-Board Diagnostics (OBD). Our infotainment antenna and tuner systems enable near-perfect reception of broadcasting services as well as mobile radio and data services. Our recent acquisition of Hirschmann Car Communications positions us to develop value-adding solutions for your design.

Hirschmann Car Communications deepens our expertise in vehicle-to-vehicle and vehicle-to-infrastructure communications. Hirshmann Car Communications provides a long-standing know-how in high-frequency (HF) technology and the development and manufacturing of transmitter and receiver systems, signal detection, and signal processing.

Whether they choose off-the-shelf solutions or customer-specific applications, our customers benefit from our cross-disciplinary expertise. With our continued commitment to research and development, state-of-the-art testing and measurement facilities, and our high degree of flexibility in production, we’ll continue to evolve as the needs of automakers evolve.

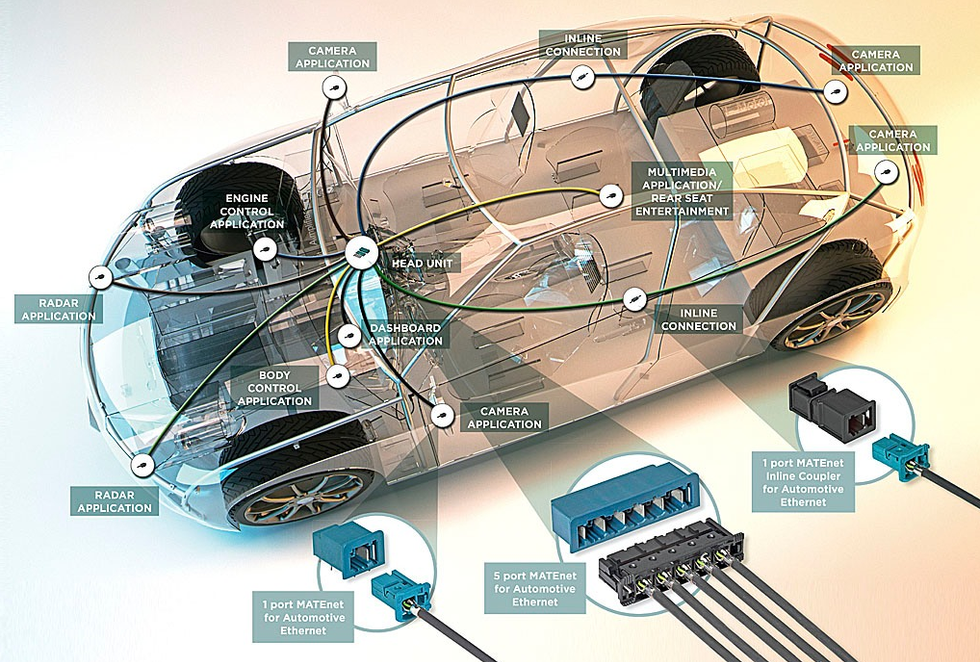

AUTOMOTIVE ETHERNET: THE BACKBONE OF CONNECTIVITY

With the increase of data production from sensors within the car and the advent of V2V, V2I, and now vehicle-to- cloud (V2C) communication, cars are becoming a major part of the IoT. They are turning into the ultimate mobile device. Automotive Ethernet will play an essential role in its success.

For example, real-time communications with other vehicles and infrastructure will provide the car with the best possible database for predictive planning. The vehicle of the future will “know” much more about its immediate environment and the route ahead. ADAS will operate in support of the driver or perform an immediate action based on this increasingly detailed environmental model of the traffic situation ahead.

The magnitude of networking is summarized in a McKinsey study focusing on the connected car: “Today’s car has the computing power of 20 modern PCs, features about 100 million lines of code, and processes up to 25 gigabytes of data per hour. As the computing capacity of cars develops further, not only is programming becoming more complex and processing speeds becoming faster, but also the entire nature of the technology is shifting. While automotive digital technology once focused on optimizing the vehicle’s internal functions, the computing evolution is now developing the car’s ability to digitally connect with the outside world and enhance the in-car experience.”9

“We provide all the pieces to enable the connectivity stream. So whatever sensor you choose, whatever architecture you choose, whatever you want to keep on the car or bring it to the cloud, we have the connectivity components that help you to manage your system, your architecture, your stream of data.”

Dominique Freckmann, Manager, Silicon Valley Tech Office

Once vehicles become an integral part of the IoT, the amount of software in cars will continue to increase and its scope will expand. A key trend that is expected to affect growth is cyber security. A connected car needs protection against hacking and data theft. To protect and prevent these incidents, the vehicle’s software will require regular updates, through software-over-the-air (SOTA) distribution to install patches that eliminate weak spots. These updates will increase the amount of data traffic—both to the car and within the car.

Utilizing this wealth of data from all these sources requires high-speed, in-vehicle networking. The challenge is to not only provide more bandwidth for bigger data packages, but also meet the OEMs’ different approaches to vehicle electronic/electrical architecture. Electromagnetic Compatibility (EMC) specifications may require different types of interconnection technology as well. Automotive Ethernet therefore requires an intelligent interconnection solution that offers the flexibility, economy, and performance for differing EMC requirement levels.

THE MATEnet INTERCONNECTION SYSTEM

TE’s MATEnet interconnection is a proactive answer to today’s and tomorrow’s requirements for vehicle connectivity. MATEnet modular and scalable connectors are specifically developed for IEEE Automotive Ethernet networking. Its miniaturized, robust, automotive—grade technology; has successfully passed severe testing and validation.

TE’s MATEnet relies on NanoMQS terminals, which are automotive-grade contacts miniaturized, contacts that offer a particularly high robustness against vibration. Standard unsealed NanoMQS connectors meet severity level 2 vibration requirements (around 3g effective random and 30g shock). Sealed connector versions can also meet vibration level 3 (“close to powertrain”) and 4 (“engine mounting”).

However, high-frequency, high-bandwidth data transfer poses strict requirements to signal integrity. The effort and cost required to fulfill individual Automotive Ethernet application needs is typically a product of measures that are integrated in the chip and the effort that goes into the channel (cable and connectors).

TE’s MATEnet was designed to offer an optimum balance between both cost curves. It delivers an excellent cost- performance ratio because it neither places a high burden on chip capabilities (size, power consumption) nor does it require high-end cabling (materials, processes, complexity).

MATE-AS RF Interconnects

ADAS units may have as many as 24 coax inputs coming from the many sensors required for detecting objects and free space around a vehicle. Coaxial cables provide an economic and easy to handle physical layer for RF-signal transmission. But coax, automotive-grade interconnection solutions such as FAKRA may not provide enough RF-performance for ADAS.

The challenge for TE was to quadruple the number of coax cables that can be terminated as compared to a FAKRA connector, and to double the amount of lines in comparison to a High Speed Data (HSD) differential signaling connector.

MATE-AX is the result. MATE-AX provide an EMI resistant and miniaturized interconnection RF-solution for existing and future coax lines. With excellent signal integrity and the long-term potential for up to 20 GHz, MATE-AX take automotive coaxial technology to the next level of performance and facilitate transmission of large uncompressed data between signal sources and ECU “servers.” By offering a higher packaging density (4 coax cables in the space of 1 FAKRA connectors; 2 coax cables in the space of 1 HSD connection), MATE-AX terminals support significant size and weight reductions, and give the industry a solid, future-proof digital signaling roadmap.

MATEnet in the Future

-

—Power-over-Data-Line (PoDL) —

Currently, electronic devices in cars are supplied with electricity over separate cables. However, the additional cables make the harness heavier, more complex, and more difficult to feed parts of the harness through narrow passageways within vehicles. It would therefore be a contribution to downsizing and light-weighting of the harness, if separate power lines were not necessary. The new concept of Power-over-Data-Line (PoDL) supports this strategy in vehicle applications. It uses the 100Base-T1 and 1000Base-T1 interfaces to supply power parallel to the signal on a single unshielded twisted pair. TE is testing PoDL in combination with MATEnet and will validate this option within the MATEnet interconnection system. Testing so far has been very positive and indicates a beneficial use with up to 48 VDC.

-

—A2B Automotive Audio Bus® —

Our MATEnet is a potential interconnection technology for the Automotive Audio Bus® (A2B), developed by Analog Devices. This digital audio bus with up to 50 Mbit (50 million bits/second) bandwidth was designed to reduce the weight of high—fidelity wiring for automobiles while significantly reducing the weight of existing cable harnesses. One potential use is multiple microphone arrays within vehicles that allow different applications such as voice recognition, active noise cancellation, and in-car communications to perform.

— HDBaseT —

HDBaseT is an emerging technology, providing up to 6Gbps (6 billion gigabit/second) full duplex data transmission, through a 15m link segment, with up to 4 inline connectors at near zero latency. It includes various protocols, such as audio and video, Ethernet, power, and consumer applications including USB and HDMI. TE has an active part in the HDBaseT Alliance, where automotive stakeholders collaborate in various technical committees to define appropriate automotive requirements and specifications. Native Networking Capabilities demonstrates the usability of unshielded twisted pair cabling, which can be compared to 100 and 1000 BASET1 applications.

Addressing multiple challenges, HDBaseT with its unprecedented bandwidth and suitability for existing UTP cabling systems like TE’s MATEnet is a key enabler for future in-vehicle connectivity.

DATA AND THE DECENTRALIZED CLOUD

Making full use of the capabilities of the 5G-enabled cloud will require faster, more robust in-vehicle data networks as well as a new generation of 5G native antennas, receivers, and connectors. But, in a future with billions of mobile devices and trillions of Internet of Things (IOT) moving massive amounts of data, it will also mean evolving the architecture of the cloud away from a centralized model to one where computing applications, data, and services are pushed to the periphery (the “edge”) of a network.10

With Edge Computing, speed is a key parameter. For instance, with Mobile Edge Computing (MEC), the current goals are: data rates up to 6 Gbps, less than 1 ms latency, mobility at 500 km/hour, and terminal localization within 1 meter. What this means in practical terms is more continuity of service with high reliability.11 In situations where computing and response need to be instantaneous (i.e., with real-time traffic reports), these decentralized nodes would handle the data loads.

Computations for things like autonomous driving would also be handled at this level. The centralized cloud core would still handle applications. Applications that require robust computing power, data aggregation, and data storage.

TE’s long history of partnering with leading enterprise and hyperscale customers—combined with our experience in data and devices—offer OEMs practical intelligence that will help them evolve vehicle technology toward making possible new opportunities in networked intelligence.

THE TE ADVANTAGE: CROSS-DISCIPLINE INTELLIGENCE

No matter which technology path OEMs choose to innovate for the connected car, TE partners with these customers early in the design process to accelerate innovation. By applying our expertise in automotive standards and knowledge we’ ve gained from decades of working with customers, we can quickly meet evolving challenges and requirements in designing for the automotive industry.

Today, there are two developments driving the automotive industry towards compact, robust high-speed communication solutions: ever-increasing data rates and the demand for miniaturization. A significant challenge around these developments is designing technology that maintains signal integrity.

Although automotive manufacturers are now starting to talk about 10Gbps data rates, since the 1990s, we have manufactured 10Gbps products. We’ve shipped massive numbers of these high-speed components for almost 15 years. Combined with our understanding of automotive requirements, we are quickly adapting our solutions to meet the needs of automobile makers.

“The Data & Devices (D&D) business at TE is at the leading edge of speed and performance. For us, a 100, 400 gig connection is next generation high speed. What we’re finding is that there’s an increasing usage of D&D core products in connected cars, such as backplane connectors, internal cabling systems, or high-speed IO. This is creating synergies between the Data & Devices group and the Automotive group at TE Connectivity.”

Amitabh Passi, VP, Strategy and Business Development, TE Communications Solutions

Miniaturized, high-speed networks also pose a fundamental challenge in thermal management and EMI. Our innovations in BLS and heat sink integration have improved efficiency and performance. Initially developed for enterprise and hyperscale data centers, these are more relevant than ever to auto manufacturers. In the car, TE products connect almost every electrical function – from alternative power systems to infotainment and sensor technologies.

In addition, TE solutions help meet the evolving challenges and requirements of the auto industry:

-

Data connectivity: Technologies based on coax, shielded, optical, and wireless mediums.

-

Power and data distribution: High reliability transmission through connecting, switching, protecting, and sensing competencies.

-

Sensing: Data-driven technology to measure position, pressure, speed, temperature, humidity, and fluid quality.

-

Weight reduction through miniaturization: TE Nanos and MCON 0.50 interconnection systems enable a reduced size for electronic components, smaller wires, and a reduced total connector package.

-

Weight reduction through shift from copper to aluminum: When applied to a typical family-size car, the shift to aluminum conductors and TE’s LITEALUM crimp can save up to two or three kilograms of weight. This efficiency reduces the weight of the car and is achieved at lower material cost.

- Reliability and experience: For several decades, TE has supported global OEMs with their electrical architectural needs, with solutions that enable cars to be safer and smarter – all while adapting to increased technical requirements.

TE is also investing in the future of connected car technologies by devoting research and develop (R&D) to the fundamentals of core connectivity, such as:

-

More power: High-voltage connections with anti-arcing and emergency shutoff features

-

Relays and circuit protection

-

New architectures to handle extra features, gadgets and power demands

-

Bigger and faster data pipes to flawlessly handle exponential growing amounts of data inside and outside the vehicle

-

Optical data pipes (fiber optics)

-

Conductive data pipes (Ethernet)

-

Wireless data pipes (antennas for Wi-Fi, Bluetooth, 4G/LTE, dedicated short range communications)

-

More information from sensors to meeting increasing demands for closed loop control

We are also a leader in materials science. Since 1957, when we developed heat-shrink tubing for our Raychem product line, TE has invested in materials science research and innovation. Today, we reinvest five percent of our revenue in research and development. In partnership with leading research institutions and our customers, our engineers are constantly searching for ways to make solutions that are lighter, greener, tougher, or more conductive. Examples of advanced materials include high-performance carbon nanotubes that reduce weight in aerospace applications, conductive inks that are making manufacturing processes cleaner, and miniaturized components that are enabling a new generation of wearable technology. Through our Advanced Development Labs, we’re exploring technologies several generations out, as we work to develop essential technologies for an increasingly connected world.

This institutional intelligence informs all our product development for automotive standard solutions.

COMMITTED TO INNOVATION

TE is committed to providing connectivity and sensor solutions that enable OEMs to put more innovation into the connected car. We design and make our products smaller and lighter, with high reliability to perform as expected in the harshest environments.

© 2018 TE Connectivity Ltd. family of companies All Rights Reserved. TE Connectivity, TE Connectivity (logo), TE and Every Connection Counts, MATE-AX and MATEnet are trademarks. All other logos, products and/or company names referred to herein might be trademarks of their respective owners.

- https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/%20Automotive%20and%20Assembly/PDFs/McK_The_road_to_2020_and_beyond.%20ashx

- https://www.statista.com/outlook/320/109/connected-car/united-states

-

Gartner, “Gartner Says By 2020, a Quarter Billion Connected Vehicles Will Enable New In-Vehicle Services and Automated Driving Capabilities,” January 26, 2015: https://www.gartner.com/newsroom/id/2970017

-

https://www.statista.com/outlook/320/109/connected-car/united-states

-

https://www.yourmechanic.com/question/when-did-cars-first-start-using-sensors

-

https://www.networkworld.com/article/3147892/internet/one-autonomous-car-will-use-4000-gb-of-dataday.html

-

https://enterpriseiotinsights.com/20170817/opinion/why-antennas-are-the- workhorse-of-the-connected-car-tag10

-

McKinsey & Company: Connected car, automotive value chain unbound. September 2014, page 11 retrieved from: https://www.mckinsey.de/files/mck_ connected_car_report.pdf

-

Garcia Lopez, Pedro; Montresor, Alberto; Epema, Dick; Datta, Anwitaman; Higashino, Teruo; Iamnitchi, Adriana; Barcellos, Marinho; Felber, Pascal; Riviere, Etienne (2015-09-30). “Edge-centric Computing: Vision and Challenges”. ACM SIGCOMM Computer Communication Review

TE Connectivity is a global industrial technology company developing electrical and electronic products engineered to reliably connect and protect the flow of data, power, and signal. TE products and solutions are used in electric vehicles and aircraft, digital factories, smart homes, life-saving medical devices, efficient utility networks, and the global communications infrastructure. Headquartered in Schaffhausen, Switzerland, TE has more than 85,000 employees, including 8,000 engineers, working alongside customers in approximately 140 countries.