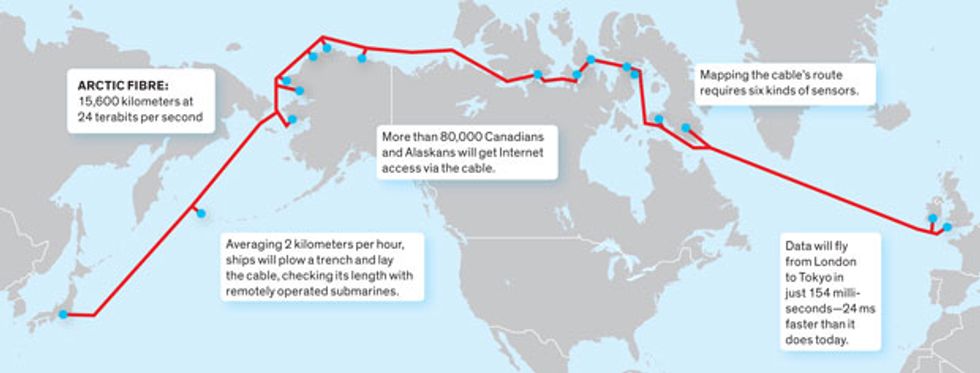

The ice that has long covered the North American Arctic is melting away, creating an opportunity for companies to capitalize on these virgin waters. Among the shipping and oil mavens with an eye on the Northwest Passage is the company Arctic Fibre, which is trying to thread a 15,600-kilometer fiber-optic cable right through it. A year from now, slow ships loaded with reels of cable will deploy to three oceans and the farthest corners of North America to begin installing the cable, meter by meter. The ocean’s depths are often a murky mystery, however, and crews must rely on sonar and sophisticated maps of the seafloor to carefully unfurl the line and keep it from twisting into loops, snagging on abandoned anchors, or dropping into underwater crevasses.

The cable’s northern route, from Tokyo to London, will bisect the Pacific, Arctic, and Atlantic Oceans and skim the northern coast of Canada and Alaska. When the route is completed, a 24-terabit connection should zoom data from one end to the other in 154 milliseconds, which is 24 ms faster than today’s fastest connection between Tokyo and London.

“The idea for an Arctic infrastructure for telecommunications has been on the back of the napkin for quite some time, but timing has really brought these things together—timing on the environment, the market, and the technology,” says Desiree Pfeffer of Quintillion Networks [PDF], an Alaska-based partner of Arctic Fibre.

But the real work is only beginning. This spring, contractors with TE SubCom will start marine surveys to map the ocean floor and chart the true course of the cable. Each section of the cable must then be custom-built to the surveyors’ specifications.

This summer, the survey team will board a ship—one like the RV Geo Explorer, owned by EGS Group—to trace every meter of the proposed path. They will use multiple types of sonar, which measure echoes in different ways to scan and chart varying depths, landslide hazards, and unexpected volcanoes or chasms. Under the water, a metal detector called a magnetometer will help them steer clear of discarded fishing equipment or cables that have already been laid. Based on all of this data, the surveyors will build maps and plot a the cable’s path, occasionally for areas of the passage that have never before been mapped [see sidebar, "Subsea Sensors"].

If all goes well, Arctic Fibre expects to start installing the cable in about a year. The timing of that installation is critical, as the passage is shrouded in ice for most of the year. There is a window of only five to eight weeks between August and October during which cable ships can maneuver through without the aid of icebreakers.

“This project has been under development for four years. Typically it takes about six years, and it will probably take us seven because of logistics and ice windows,” says Doug Cunningham, CEO of Arctic Fibre. Cunningham has financed or led other fiber-optic cable ventures, including projects for Antilles Crossing, GlobeNet Communications, and TeleBermuda.

When the time is right, the cable is wound around big reels and loaded onto the back of one of three cable ships—one for each ocean to be traversed. Those ships trundle along the route at about 2 km per hour, around the clock. In the ship’s first pass over a segment, it drags a heavy anchor called a grapnel to smooth out the seafloor and remove any debris.

During the next pass, the cable is fed from the back of the ship at a rate that speeds or slows with the ship’s pace. At any given time, the crew lets out about 2 percent more cable than needed, providing the proper slack for the cable to lie as intended rather than holding taut or falling loosely into loops on the seafloor.

As an added protection against the anchors and trawl nets of fishermen, at depths shallower than 1,000 meters the crew deploys a plow to bury the cable in a trench that measures 1 to 3 meters deep rather than simply laying it across the seafloor. Once it’s in the water, the plow maneuvers atop two hydraulic skis, using two angled plates at its nose to dig the trench. As the plow passes, it feeds the cable into the trench and funnels soil into the furrow to bury it.

Fiber-optic technology has been in use for 50 years, and these marine installation methods are proven, says Cunningham. “We’re using many of the same installation techniques that [the] oil and gas industry in Alaska has been using on the North Slope for 30 to 35 years—there’s not much difference between an oil pipeline and a fiber-optic cable, except ours is smaller and a little easier to manage,” he says.

Close to shore, crews drill sideways through the bank to connect the cable to landing stations across its northern route. From these stations, the cable will provide broadband access to underserved communities throughout Alaska and Canada. “All broadband is good broadband, and the more broadband out there, the better,” says Katie Reeves, former program coordinator with Connect Alaska, a broadband advocacy group. Here, the cable also connects to onshore power stations, which pump in 1.5 amperes of direct current. This current powers repeaters located where the cable’s sections are spliced together to amplify the optical signals and spur them from one end to the other.

Cunningham says the project’s biggest challenge is building those landing stations in remote places. “None of these places in Canada have a road to them,” he says. “That’s also the case for, I think, six of the seven that we plan to be at in Alaska. Getting equipment into these places will be difficult. Getting a drill and people who are competent to drill—the logistics of getting things in and out is perhaps the biggest challenge altogether.”

The ocean also poses risks to the cable once it is installed. Fish trawling and ship anchors cause about two-thirds of subsea cable outages worldwide. “The problem with that project is the fact that it’s in the north,” says Paul Kravis, vice president of International Telecom, a company that has done logistical work in northern Canada. “If this cable gets broken in the wintertime right now, there’s not going to be any vessel that can fix it.” Still, Cunningham says part of his advantage is that the ocean provides natural protection from vandalism, another common cause of interruptions.

If all goes according to plan, the cable could be up and running as early as the end of 2016—though Arctic Fibre has not announced an official in-service date. The cable is built to last for at least 25 years, after which the company will abandon it to the ocean.

Subsea Sensors

A Canadian company called Arctic Fibre is planning to thread the Arctic with the region’s first fiber-optic cable. This summer, surveyors will use up to six types of sonar and mapping tools, each with a distinct role in deciding the cable’s perfect course. The sensors will gather data on seismic activity, identify seams of rock in the seafloor, and warn surveyors to steer clear of subsea hazards.

Side scan: Uses variations in the strength of echoes from the seafloor to sketch a black-and-white image that reveals crevasses or volcanoes to avoid.

Single beam: Measures depth to seafloor in a straight line by shooting a single beam of sound down from the ship. This records the exact depth for each inch of the cable’s intended course.

Multibeam: Measures depth to the seafloor in a wider swath than single-beam sonar does, which helps the survey team identify alternate paths (if the cable must be rerouted) and potential rock-slide risks.

Sub-bottom: Deploys a low-frequency sonar to detect patterns in the sediment below the seafloor. This data tells the crew whether to expect sand or rock when digging a 1-meter trench for the cable.

Ultrashort base line: Integrated into an underwater vehicle tethered to a ship. The vehicle is equipped with attitude sensors to detect pitch and roll and also a transceiver to send and receive acoustic signals. The tethered vehicle tracks the location of a remotely operated vehicle that digs the trench or inspects the cable.

Magnetometer: Measures the magnetic field of the seafloor and can help find abandoned pipelines or old cables that must be avoided.

About the Author

Amy Nordrum, a freelance journalist who lived in Alaska for three years, experienced the state's lack of communications infrastructure firsthand. This is her second story for IEEE Spectrum on the Arctic Fibre cable and what it will do for broadband access in the far north.