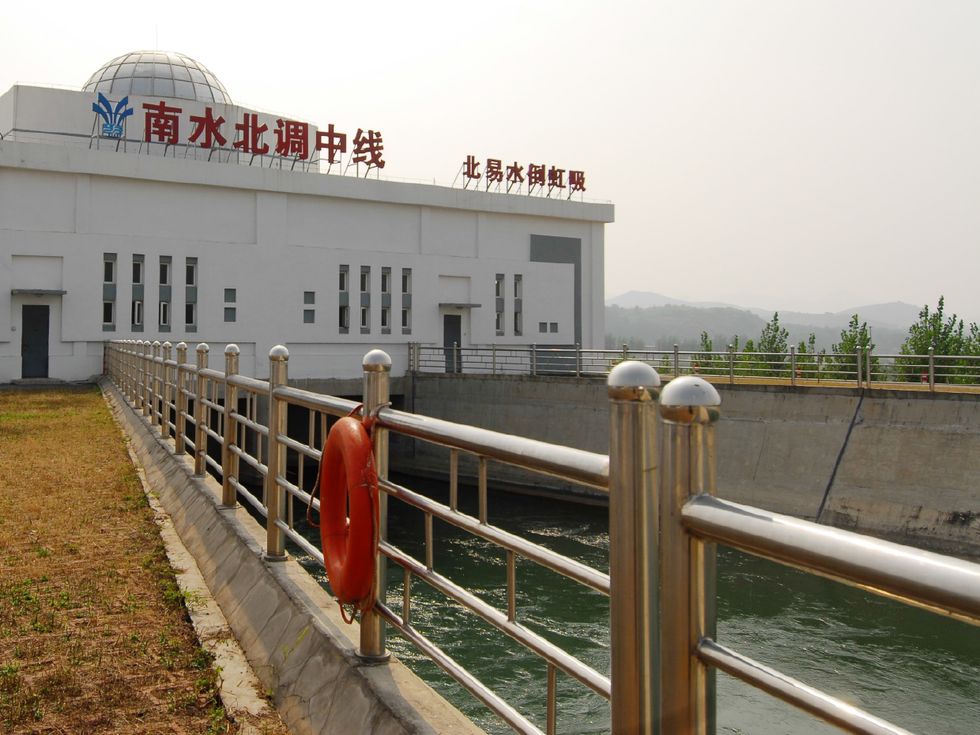

As an engineering feat, China’s massive South-to-North Water Diversion Project is a stunner. Three artificial canals, each more than 1,000 kilometers long, are in various stages of completion and designed to reroute water from the country’s rainy south to its parched north.

The massive Internet-of-Things (IoT) network that has been quietly overseeing the middle route is impressive in its own right. More than 100,000 individual sensors stud the 1,400-kilometer waterway, which connects the Danjiangkou reservoir to Beijing and Tianjin. For the last year, it’s been scanning the canal for structural damage, tracking water quality and flow rates, and watching for intruders, whether humans or animals.

“This system benefits more than 50 million people daily, not mentioning the people along the project,” says the IoT network’s technical lead, Yang Yang, director of the CAS Key Lab of Wireless Sensor Network and Communication at the Shanghai Institute of Microsystem and Information Technology (SIMIT), part of the Chinese Academy of Sciences. He says what they learn from the network will likely be applied to other massive infrastructure projects, including the Eastern and Western Routes of the water transfer system, as well as more modest endeavors, like monitoring the glass facades of skyscrapers.

Planning for the IoT network started back to 2012. Yang and his team, including Wuxiong Zhang, associate professor at SIMIT, Chinese Academy of Sciences, spent two weeks traveling the length of the canal, assessing its needs.

They saw many challenges. The water traversed regions prone to earthquakes, making infrastructure vulnerable to damage. The water’s flow would need to be controlled so that none of it would go to waste. Its quality would also need to be checked periodically to ensure no pollutants or toxins made their way into city drinking water supplies. In some places, local villagers scaled the fence to fish or swim in the water. That created safety risks.

Yang and his team grouped the challenges they saw into three broad categories—infrastructure, water, and security—and, after some discussions, settled on more than 130 different kinds of Internet-connected sensors to install along the canal. Infrastructure sensors measuring stress, strain, vibration, displacement, earth pressure, and water seepage were embedded in the ground adjacent to the canal and in the concrete banks and bridges as well as the 50 dams built to control the water’s flow.

Probes that measure water quality and flow rate were attached to the steel support columns that hold up the bridges. Video cameras were spaced every 500 meters along the entire structure.

With all these sensors placed, the question emerged: how to send the data once it was collected? Although some sections of the canal had access to a fiber-optic Internet connection, other areas had no access and passed through remote areas with spotty or absolutely no cellular network service. As a solution, Yang and his team developed the so-called Smart Gateway to receive data continuously from local sensors and then transmit it to a cloud server using whatever signal was available at the moment. That could include fiber, Ethernet, 2G, 3G, 4G, Wi-Fi, or Zigbee.

“The Smart Gateway can learn the availability of the connection to the cloud. After a successful transmission, it will follow that network next time. Otherwise, it will try another one,” says Zhang.

The Smart Gateway periodically transmits data to the nearest server, which may be any one of 47 regional branch servers in counties along the canal. Under normal circumstances, the transmissions occur at intervals of 5 minutes, 30 minutes, or once a day, depending on location and water resources in the area. If some special event happens such as an earthquake or a chemical spill, the data will be sent immediately and continuously to the cloud. From there the data is stored or forwarded to any of the five administrative servers in provincial cities between the Danjiangkou reservoir and Beijing, to ultimately reach the main server center in Beijing.

Yang and his team designed a Web platform and interface, which allows people working at the server stations to read the data and respond to any alerts via a website, thus enabling the central management team in Beijing to always learn the latest developments at remote sites and make the right decisions in real time. Because the network is isolated from the World Wide Web, says Zhang, there is less of a risk that the data will be hacked by outsiders.

“To me, this is a good example of IoT applied to critical infrastructure,” says Adam Drobot, chair of the IEEE IoT Activities Board and chairman of Open TechWorks, an Internet security and IT consultancy firm. “You build it so it’s protected to begin with and not as an afterthought.”

Yang says that the biggest challenge facing the South-to-North Water Diversion Project is a large, 4-km tunnel about 7 meters in diameter, which goes underneath the Yellow River. He would like to see underwater robots developed eventually that can monitor and survey the tunnel more effectively and efficiently.

Yang is also working to turn more lab-developed IoT technologies into new products and services. For example, his team is developing a network to monitor the integrity of the glass facades of skyscrapers. Should a glass pane become weak or cracked, the IoT network would sense it and alert a maintenance operator about not only the vulnerable glass pane that needed to be replaced but also its exact size and shape—all before the panel cracked and crashed to the street below.

“We now have more and more sensors and more and more methods to make our environment smarter,” says Yang.

An abridged version of this post appears in the April 2018 print issue as “Sensor Network Monitors 1,400-km Canal.”

Tracy Staedter is a science writer, editor, writing coach, and consultant. Over the 20-plus years of her career, she has covered a range of science and technology stories from astrophysics to zero waste. She worked on staff for such publications as Astronomy, Scientific American Explorations, MIT Technology Review, DNews, and Seeker. She also wrote the illustrated book, Rocks and Minerals (part of the Reader’s Digest Pathfinders series) and founded the Fresh Pond Writers workshop for fiction and creative nonfiction writers. In addition to contributing to IEEE Spectrum, she writes for Discover, Smithsonian Air & Space, Mercury Magazine, Inside Science, and more.