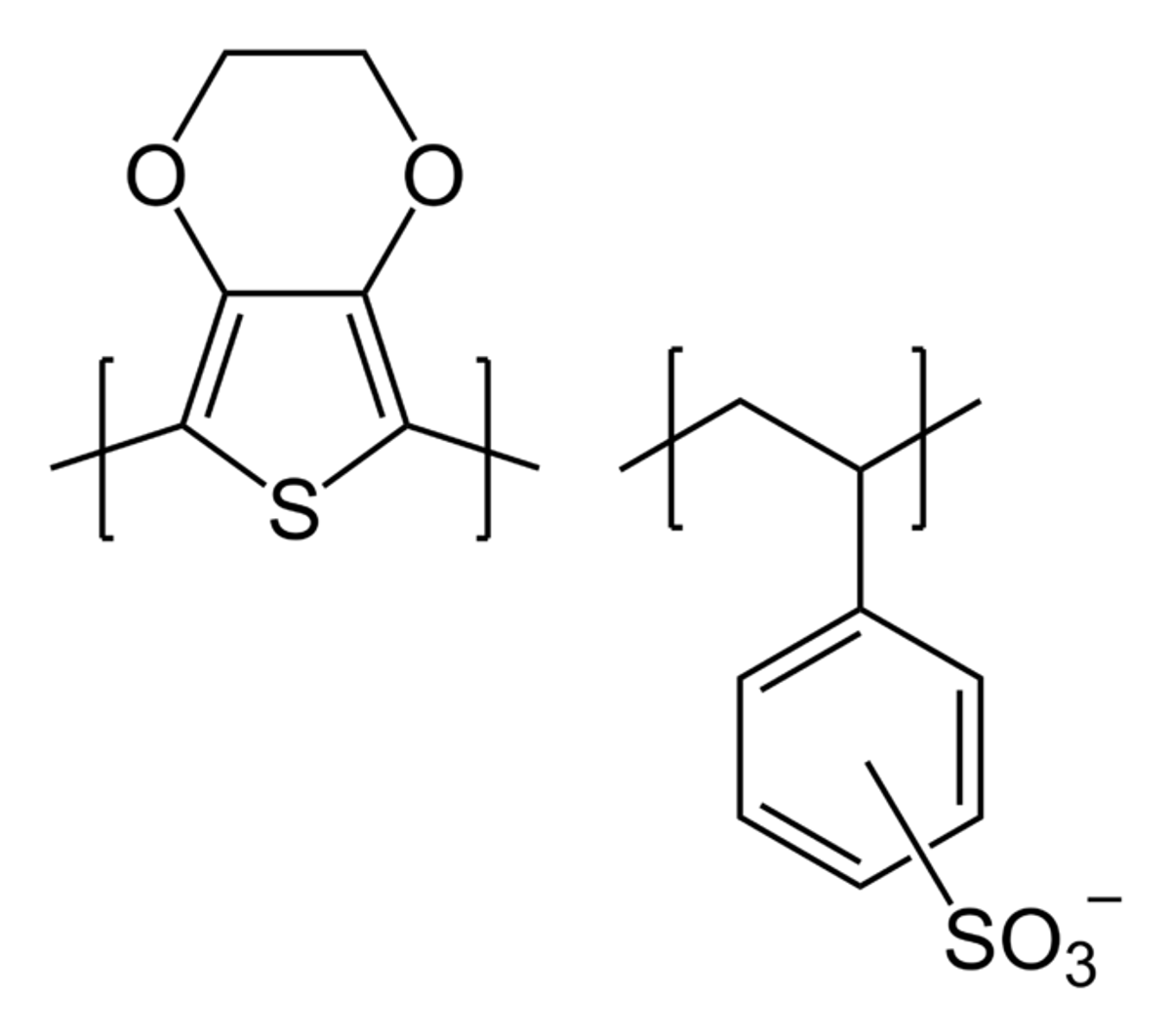

But because of indium’s growing cost and limited availability—and because it is brittle, and therefore not suitable for future flexible displays—researchers have for years sought a viable substitute. Scientists at the U.S. Department of Energy’s Ames Laboratory and Iowa State University's Microelectronics Research Center recently announced that they may have found that particular holy grail—in the 15-year-old polymer poly (3,4-ethylene dioxythiophene):poly (styrene sulfonate), aka PEDOT:PSS. Previously, PEDOT:PSS wasn’t conductive enough or transparent enough to work in displays; it’s more commonly been used for coating photographic films to prevent static discharge. But Ames senior scientists Joseph Shinar and Ruth Shinar, and research scientist Min Cai, and their colleagues have developed a multilayer PEDOT:PSS fabrication technique that, with other manufacturing tricks, improved both conductivity and transparency. The research was published in the journal Advanced Materials.

University of Cincinnati associate professor Jason Heikenfeld, considering the researchers results, said that Ames’ version of PEDOT:PSS is not superior to the best ITO in performance as a basic transparent conductor. But, he indicated, the results are good for PEDOT:PSS. Joseph Shinar agrees, but notes that in spite of the lower transparency and lower conductivity of the multilayer PEDOT:PSS compared with indium tin oxide, the PEDOT:PSS-based devices are more efficient than the indium-tin-oxide-based devices because of a favorable micro optical cavity effect.

PEDOT:PSS isn’t the only technology taking aim at indium tin oxide’s dominance of OLED electrodes. Another leading competitor, Heikenfeld says, has been silver nanowire ink, being commercialized as ClearOhm. Heikenfeld pointed out that ClearOhm has shown amazing transparency, but the semiconductor community has a deep understanding of how to work with PEDOT:PSS, and PEDOT:PSS has some unique current-injection properties that are desirable for OLEDs . But he’s not convinced that anything yet appears to be the ultimate ITO alternative.

Paul O’Donovan, principal research analyst in Gartner’s Semiconductor Research Group, is more excited. “This is a significant advance in the commercial development of OLEDs,” he told Spectrum. “Not only does PEDOT:PSS offer an over 40 percent efficient improvement over indium tin oxide, but it’s flexible, opening up the real proposition of a range of flexible displays for pocket-sized to projection-screen-sized displays. And the added bonus is that PEDOT:PSS is lower cost and not in short supply. This development will help with reducing the manufacturing costs of large OLED TV panels, which is good news for consumers.”

Image: PEDOT:PSS. Source: Wikimedia Commons

Tekla S. Perry is a senior editor at IEEE Spectrum. Based in Palo Alto, Calif., she's been covering the people, companies, and technology that make Silicon Valley a special place for more than 40 years. An IEEE member, she holds a bachelor's degree in journalism from Michigan State University.