Last week, El Segundo, Calif.-based Efficient Power Conversion, announced that it’s offering two types of power transistors made from gallium nitride that it has priced cheaper than their silicon counterparts.

“This is the first time that something has really been higher performance and lower cost than silicon,” CEO Alex Lidow says. “Gallium nitride has taken the torch and is now running with it.”

Gallium nitride and silicon carbide have long been attractive alternatives to silicon in power electronics: they’re capable of faster switching speeds and can handle a higher voltage than a same-sized silicon device. But silicon has long been less expensive to manufacture.

Efficient Power Conversion (EPC) has two cheaper offerings: a 60-volt and a 100-V power transistor. The company says such devices should be ideally suited for a range of applications, including wireless power transfer, laser ranging systems for cars, and RF transmitters.

EPC builds its devices on silicon wafers that have a layer of gallium nitride grown on top [pdf]. Those wafers are pricier than plain silicon wafers. But because the electric field strength needed to break down a gallium nitride crystal is higher than what’s needed in silicon, gallium nitride devices can be made smaller. In principle, that means more devices can be made from the same wafer, which drives down cost. Of course, that all depends on yield—the number of working devices you can produce per wafer—and on economies of scale.

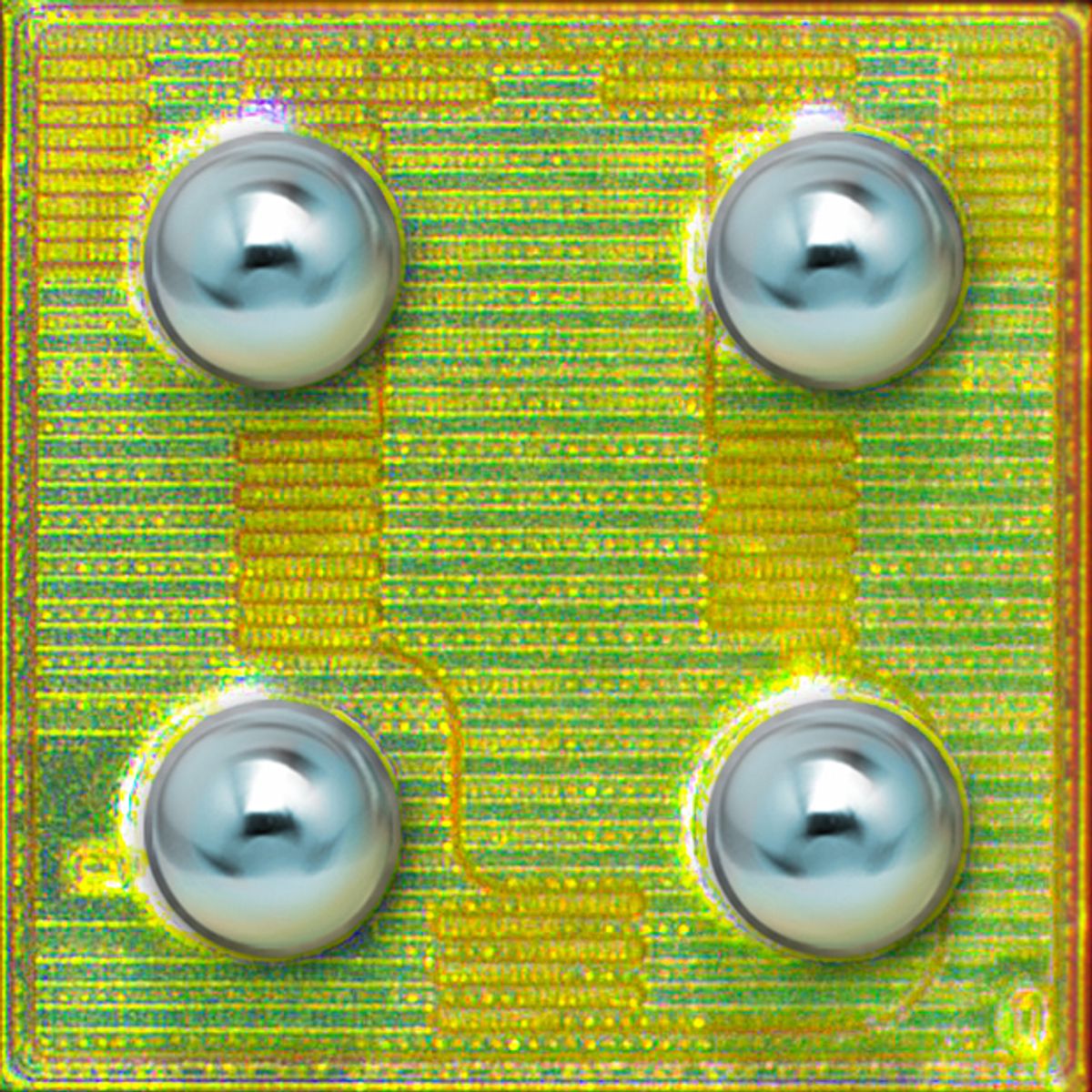

Also crucial to driving down cost, Lidow says, is the company’s transistor architecture: It has all the electrical connections (source, drain, and gate) on one side of the device, making it easily mountable on a printed circuit board. To achieve the same thing, a silicon-based power MOSFET needs special packaging. That packaging makes up, on average, about 50 percent of a power MOSFET’s cost, EPC says.

“This is the first time I’ve seen somebody hold up a sign and say ‘gallium nitride cheaper than silicon’,” says Steve Ohr, an analyst at Gartner. “It is as far as I can tell an apples to apples comparison.”

But he notes this is part of a wider effort to progressively drive down gallium nitride costs. “Breakthrough might be too strong a word considering everybody’s been trying to improve their yields.”

Other companies are working hard on gallium nitride power transistors, he says, including Goleta, Calif.-based Transphorm, and industry giant Infineon, which recently acquired Lidow’s former company, International Rectifier. One of the much desired targets is power electronics that can operate up to 600 V, Ohr says, a class that includes industrial power supplies and interfaces between homes and the electric grid.

Lidow says EPC decided to first go after applications at 200 V or less in order to pursue new applications silicon can’t easily reach, a category that includes virtual reality and small medical imaging systems. “We wanted to enable some new things as a first priority, as opposed to simply improving existing applications,” he says.

Rachel Courtland, an unabashed astronomy aficionado, is a former senior associate editor at Spectrum. She now works in the editorial department at Nature. At Spectrum, she wrote about a variety of engineering efforts, including the quest for energy-producing fusion at the National Ignition Facility and the hunt for dark matter using an ultraquiet radio receiver. In 2014, she received a Neal Award for her feature on shrinking transistors and how the semiconductor industry talks about the challenge.