Demand for battery-making metals is projected to soar as more of the world’s cars, buses, and ships run on electricity. The coming mining boom is raising concerns of environmental damage and labor abuses—and it’s driving a search for more sustainable ways of making batteries and cutting-edge electronics.

Artificial intelligence could help improve the way battery metals are mined, or replace them altogether. KoBold Metals is developing an AI agent to find the most desirable ore deposits in the least problematic locations. IBM Research, meanwhile, is harnessing AI techniques to identify alternative materials that already exist and also develop new chemistries.

KoBold, a mining exploration startup, says its technology could reduce the need for costly and invasive exploration missions, which often involve scouring the Earth many times over to find rare, high-quality reserves.

“All the stuff poking out of the ground has already been found,” said Kurt House, co-founder and CEO of the San Francisco Bay area company. “At the same time, we’ve realized we need to massively change the energy system, which requires all these new minerals.”

KoBold is partnering with Stanford University’s Center for Earth Resource Forecasting to develop an AI agent that can make decisions about how and where explorers should focus their work. The startup is mainly looking for copper, cobalt, nickel, and lithium—metals key to making electric vehicle batteries as well as solar panels, smartphones, and many other devices.

Jef Caers, a professor of geological sciences at Stanford, said the idea is to accelerate the decision-making process and enable explorers to evaluate multiple sites at once. He likened the AI agent to a self-driving car: The vehicle not only gathers and processes data about its surrounding environment but also acts upon that information to, say, navigate traffic or change speeds.

“We can’t wait another 10 or 20 years to make more discoveries,” Caers said. “We need to make them in the next few years if we want to have an impact on [climate change] and go away from fossil fuels.”

Light-duty cars alone will have a significant need for metals. The global fleet of battery-powered cars could expand from 7.5 million in 2019 to potentially 2 billion cars by 2050 as countries work to reduce greenhouse gas emissions, according to a December paper in the journal Nature. Powering those vehicles would require 12 terawatt-hours of annual battery capacity—roughly 10 times the current U.S. electricity generating capacity—and mean a “drastic expansion” of metal supply chains, the paper’s authors said.

Almost all lithium-ion batteries use cobalt, a material that is primarily supplied by the Democratic Republic of Congo, where young children and adults often work in dangerous conditions. Copper, another important EV material, requires huge volumes of water to mine, yet much of the global supply comes from water-scarce regions near Chile’s Atacama desert.

For mining companies, the challenge is to expand operations without wreaking havoc in the name of sustainable transportation.

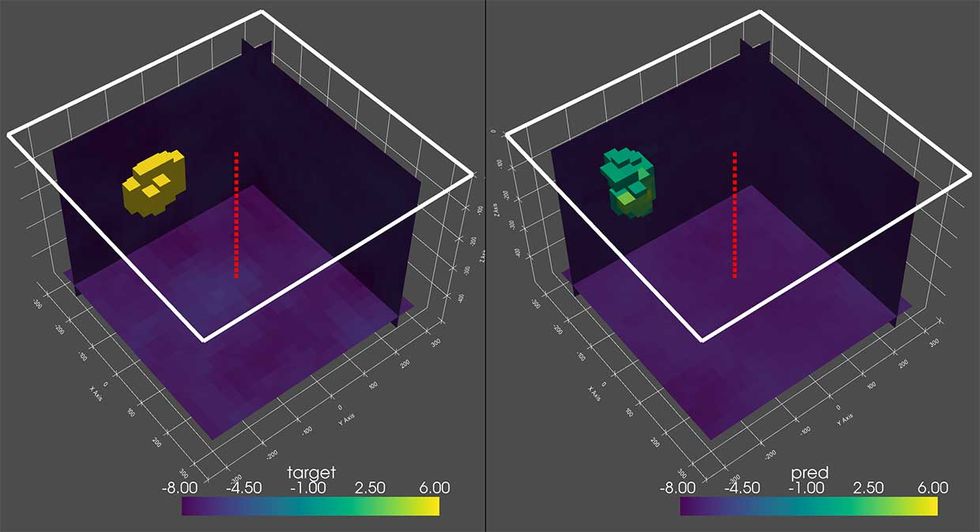

KoBold’s AI-driven approach begins with its data platform, which stores all available forms of information about a particular area, including soil samples, satellite-based hyperspectral imaging, and century-old handwritten drilling reports. The company then applies machine learning methods to make predictions about the location of compositional anomalies—that is, unusually high concentrations of ore bodies in the Earth’s subsurface.

Working with Stanford, KoBold is refining sequential decision-making algorithms to determine how explorers should next proceed to gather data. Perhaps they should fly a plane over a site or collect drilling samples; maybe companies should walk away from what is likely to be a dud. Such steps are currently risky and expensive, and companies move slowly to avoid wasting resources.

The AI agent could make such decisions roughly 20 times faster than humans can, while also reducing the rate of false positives in mining exploration, Caers said. “This is completely new within the Earth sciences,” he added.

KoBold, which is backed by the Bill Gates-led Breakthrough Energy Ventures, is already exploring three sites in Australia, North America, and Sub-Saharan Africa. Field data collected this year will provide the first validations of the company’s predictions, House said.

As the startup searches for metals, IBM researchers are searching for solvents and other materials to reduce the use of battery ingredients such as cobalt and lithium.

Research teams are using AI techniques to identify and test solvents that offer higher safety and performance potential than current lithium-ion battery options. The project focuses on existing and commercially available materials that can be tested immediately. A related research effort, however, aims to create brand-new molecules entirely.

Using “generative models,” experts train AI to learn the molecular structure of known materials, as well as characteristics such as viscosity, melting point, or electronic conductivity.

“For example, if we want a generative model to design new electrolyte materials for batteries— such as electrolyte solvents or appropriate monomers to form ion-conducting polymers—we should train the AI with known electrolyte material data,” Seiji Takeda and Young-hye Na of IBM Research said in an email.

Once the AI training is completed, researchers can input a query such as “design a new molecular electrolyte material that meets the characteristics of X, Y, and Z,” they said. “And then the model designs a material candidate by referring to the structure-characteristics relation.”

IBM has already used this AI-boosted approach to create new molecules named called photoacid generators that could eventually help produce more environmentally friendly computing devices. Researchers also designed polymer membranes that apparently absorbs carbon dioxide better than membranes currently used in carbon capture technologies.

Designing a more sustainable battery “is our next challenge,” Takeda and Na said.