Plant-based burgers that taste a heck of a lot like the real thing are now at your local Burger King. And you can find realistic meatless ground beef and sausages at grocery stores. As the next big thing in sustainable and cruelty-free meat, some startups are growing it in labs from animal cells. In December, Singapore became the first country to allow sales of lab-grown chicken from U.S. startup Just Eat.

But the founders of Barcelona-based Novameat want to take a bigger leap. They plan to go beyond chicken strips and processed “meat” to the chewy, muscle-y, juicy taste of whole meat cuts. “We want to create the Tesla Roadster or iPhone moment for the future of food,” says CEO and founder Giuseppe Scionti. “Alternative meats shouldn’t just be for the environment or animals or health, they should be superior compared to what they’re trying to compete with. The Holy Grail is pork and steak.”

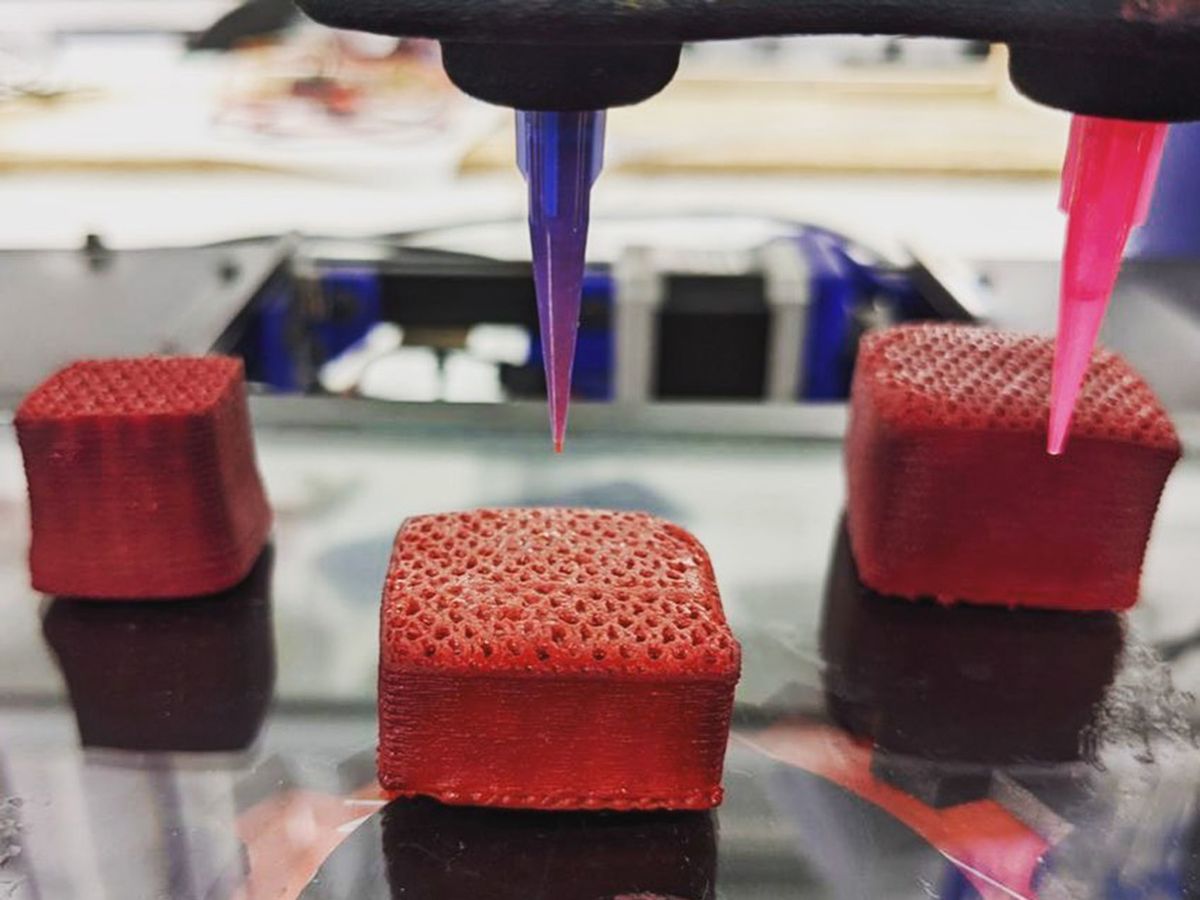

The company is using 3D-printing to get there. In what could be a game-changer for the alternative meat industry, they have now made the world’s largest piece of 3D-printed whole-cut meat analog. And they say their 3D-printing process 150 times faster than their competitors, allowing them to make 1.5 tons of meat substitute per hour.

Creating a sirloin steak, with its fibrous protein and marbled fat, from plant-based proteins is a tough recipe to perfect. Novameat’s microextrusion technology, which produces 100–500 micrometer-wide fibers from different ingredients and combines them in precise ratios and organized microstructures, is key to mimicking the mouthfeel, taste, appearance, and nutritional properties of animal meat, says senior food engineer Joan Solomando Martí. The three-year old startup has been using vegetable fat and non-soy plant proteins to make realistic 3D-printed steaks.

The latest 3D-printed whole-cut prototype was made with the company’s new hybrid meat analog, which they make by adding mammalian fat cells to a biocompatible plant-based scaffold. The cells are grown separately using traditional cell culturing techniques, and then added to the scaffolds, where they produce fatty acids or proteins. “This allows us to create beef muscle cuts, pork muscle cuts, and we are now also exploring fish and seafood.”

Making larger sizes of this hybrid meat analog is difficult, he adds. “You want diffusion of nutrients and oxygen into the structure otherwise cells in the middle of the structure will die. So you need a microporous, interconnected structure to fill the ingredients in a uniform way. This is supercomplicated.”

The texture of this hybrid meat is realistic, but the taste isn’t quite there yet. Scionti and Marti are now exploring whether they want to focus on their plant-based meat or start a full production line for the cultured meat.

Whatever they chose, they will be part of a booming alternative meat industry. Rising consumer demand for fake meat has investors flocking to companies like Beyond Meat and Impossible Foods. These companies’ shares are soaring following deals with major brands like PepsiCo, McDonald’s and Taco Bell. But even though plant-based meat is inching closer to the price of regular meat, its high costs remain a major hurdle.

3D-printing technology could help cut costs further. Novameat isn’t the only player in this field. Israeli startups Redefine Meat and Aleph Farms are both racing to get their 3D-printed plant-based steaks on people’s plates. On February 9, Aleph Farms unveiled the first 3D-printed rib-eye steak, and a week later Redefine announced that it has raised $29 million in financing.

Scionti’s background in tissue engineering—he was a professor of bioengineering before starting Novameat—might give him a leg up on those competitors. He says Novameat’s products are superior because they much more closely mimic the alignment and hierarchy of components natural muscle tissue, from the orientation of protein molecules to the microstructural alignment of muscle filaments that control texture and are bundled together to compose millimeter scale muscle fibers.

The company is now partnering with Barcelona-based Michelin star restaurant Disfrutar, ranked 9th best in the world, to test and develop their products.

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.