Mid-infrared spectrometry can assist chemical sensing, environmental monitoring, and disease diagnosis. Conventional mid-infrared spectrometers are highly developed, but sometimes bulky, assemblies: a broadband thermal emitter, an interferometer, a separate broadband detector, external optics, and a sample cell, feeding in to Fourier-transform analyzer to break the signal down and analyze absorption at a variety of frequencies.

Sometimes, though, you need quick answers when far from the laboratory. A research team at the Technical University of Vienna (TU Wien) is designing a single-chip device to meet what the leader of the team calls the “challenging task” of making “mid-infrared spectroscopy accessible to remote areas, where conventional power supply and laboratory equipment” are rare or nonexistent.

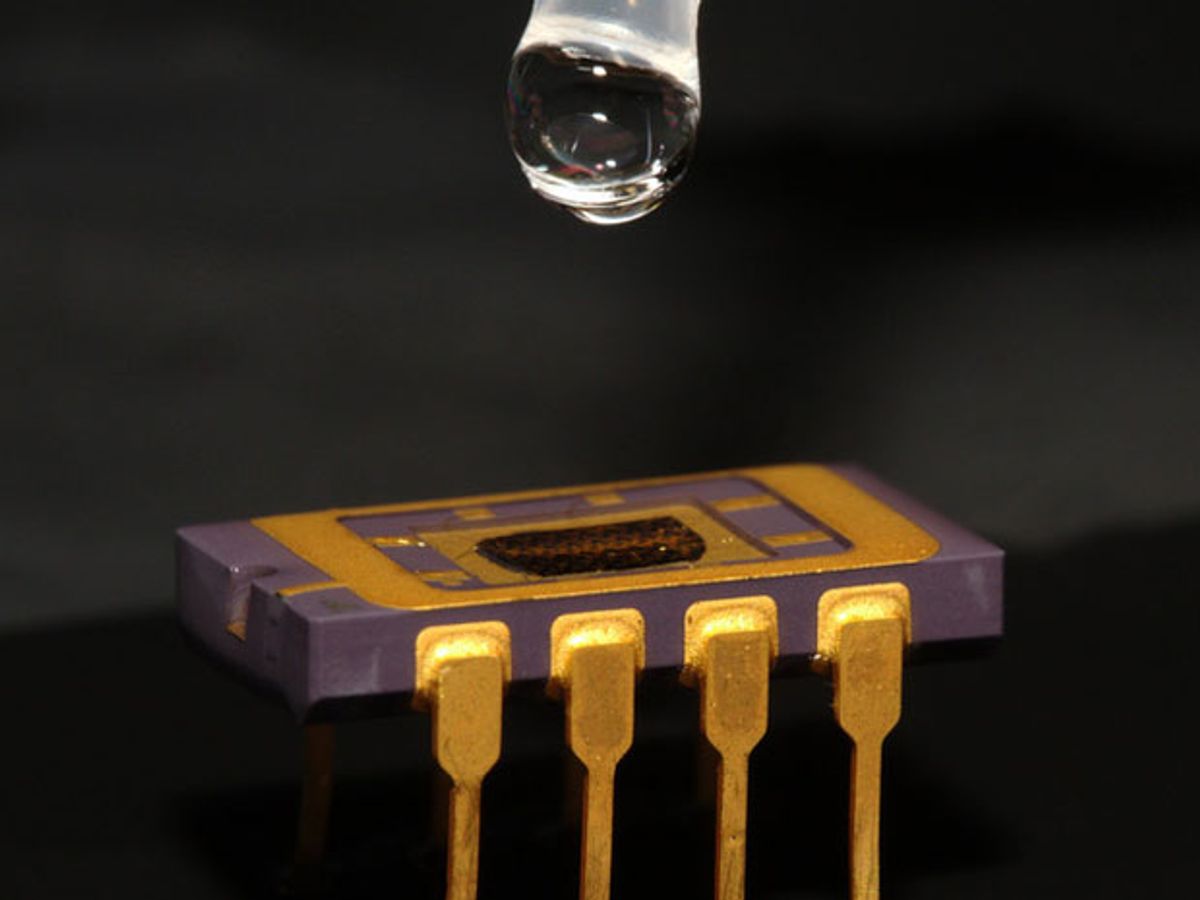

Benedikt Schwarz, lab chief Gottfried Strasser, and their colleagues at the university’s Institute for Solid State Electronics and Center for Micro- and Nanostructures have built an easy-to-fabricate lab-on-a-chip that integrates a mid-infrared (6.5-micrometers wavelength) laser, a plasmonic waveguide (which also functions as a sample chamber), and a detector into a device that can identify components in gases or liquids by their absorption signatures.

The laser and detector are, in fact, essentially the same device, a bi-functional quantum cascade laser/detector (QCLD). The QCLD can be switched from emitter to receiver by changing the applied bias, so the same fabrication process can produce both structures at the same time.

A conventional laser emits light when an electron crosses a band gap in a relatively homogeneous semiconductor to annihilate a hole—one hole, one photon. The quantum cascade device consists of nanometers-thin alternating layers of two materials. (In this case, 26 layers of indium-aluminum-arsenic alternating with indium-gallium-arsenic). In the QCLD, electrons can make an energy transition, emit a photon, and then tunnel into the next layer to emit another, creating the cascade and delivering a stronger signal.

The TU Wien group has published a good deal about the construction and control of quantum cascade lasers (see contributions to Applied Physics Letters and the IEEE Conference on Lasers and Electro-Optics), but the current work, reported in Nature Communications, focuses on the waveguide ”sample chamber.”

The waveguide, a stripe of silicon nitride laid down (by molecular beam epitaxy) between laser and detector, captures the laser beam as a plasmon, a wave that is confined in a restricted region stretching from just below the surface to a small distance above it. About 96 percent of the beam’s energy is confined in a layer above the stripe surface, and varying the stripe’s dimensions changes the parameters of the plasmon.

Schwarz and his colleagues evaluated stripes 15 micrometers wide, up to 500 nanometers thick, and 5, 50, and 100 micrometers long. In particular, the thicker the SiN layer, the more tightly the beam is constrained to the area above the stripe’s surface: while the beam might reach up to a height of 50 micrometers on a raw gold surface, it is compressed into a layer about one-tenth that thick over a 200-nanometer-thick bed of silicon nitride.

The waveguide tremendously boosts the coupling efficiency—the ratio between the energy received at the detector to the energy emitted from the laser. Without a waveguide, a laser and detector separated by 100 micrometers of raw gold has a coupling efficiency of almost zero. With the waveguide, the coupling efficiency can climb to about 40 percent.

This compression of the laser creates a virtual sample cell—one without walls, open to the environment, and operating at room temperature. A drop of fluid or a breath of gas can be sampled by bursts of 6.5 micrometer radiation, each 100 nanoseconds long, repeated 5000 times a second.

By gauging the amount of energy the sample absorbs, the single-chip spectrometer can measure its composition. The researchers tested their device with single drops of ethanol-water solution. In about a tenth of a second (since resolution increases with the square root of the sampling interval), the device could correctly gauge the ethanol concentration with a resolution of about 0.06 percent over the wide range from 0 to 60 percent (or, as I think of it, spring water to 120 proof).

With its wide dynamic range, high resolution, relatively simple and inexpensive fabrication, and single-chip robustness, the “monolithically integrated mid-infrared lab-on-a-chip” may be able to break analyses out of the lab and get them into the field.

Photo: TU Wien

Douglas McCormick is a freelance science writer and recovering entrepreneur. He has been chief editor of Nature Biotechnology, Pharmaceutical Technology, and Biotechniques.