If getting flying cars to work has been a challenge, electric flying cars are an even tougher nut to crack, due to the weight of the batteries required and how quickly they must be able to pump out energy. But a new twist on lithium-ion batteries may help them become reality.

Electric vertical takeoff and landing (eVTOL) aircraft have attracted increasing attention for urban air mobility services that could open sky corridors in cities for travel. By combining the convenience of helicopters when it comes to local takeoff and landing with the efficient aerodynamic flight of airplanes and the low noise and environmental impact of electric vehicles, electric flying cars might help cities reduce traffic congestion. Indeed, a 2020 report from management consultant firm Roland Berger in Munich, Germany, identified 95 ongoing eVTOL projects worldwide.

However, developing batteries for electric flying cars has been a challenge. Researchers have to worry about their weight, since they have to fly. They must deliver very high power while the vehicle moves vertically during takeoff and landing. They also need high energy densities to stay aloft a useful amount of time in the air.

In addition, since the commercial model for eVTOL aircraft will likely initially involve air taxi services, their batteries will also need to recharge quickly and often so they can earn high revenues during rush hours. They may each need to make 15 trips during the morning rush hour and another 15 during the evening rush hour to justify their cost—for example, from a city to an airport, carrying three to four people about 80 kilometers, says study senior author Chao-Yang Wang, an automotive, mechanical, chemical and materials engineer and director of the Electrochemical Engine Center at Pennsylvania State University.

A number of these desirable features work against each other, Wang notes. For example, fast charging usually reduces the number of possible recharge cycles, and high energy densities reduce charging speeds.

Now Wang and his colleagues have developed prototype battery designs they say can support 80-kilometer eVTOL trips with energy densities of 271 watt-hours per kilogram. These lithium-ion batteries can sustain more than 2,000 fast recharging cycles over their lifetimes, and recharge in just five to 10 minutes.

“The first generation of batteries for commercially viable flying cars is now available,” Wang says.

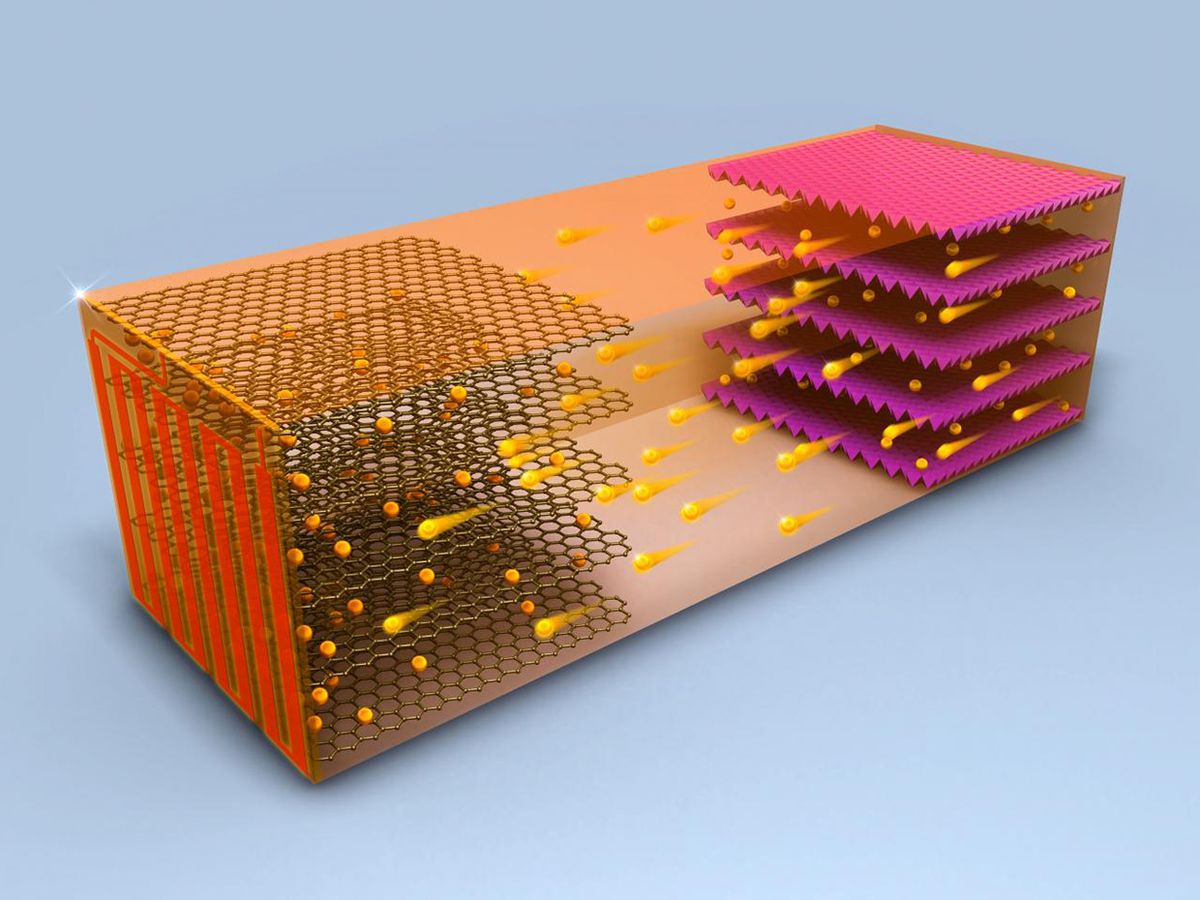

The scientists relied on technology they developed for standard electric vehicles that incorporate 10-micron-thin nickel foils into batteries to help them rapidly heat to 60 degrees Celsius. Heating batteries can help them rapidly charge without forming the kinds of lithium spikes that can damage their innards and cause short circuits.

Heating can also help electric flying cars deal with a problem related to how their batteries are never allowed to completely discharge while they are in operation, as they always have to retain some charge to stay in the air and to land. When a battery is empty, its resistance to charging is low, but the higher its remaining charge, the more slowly it recharges. Heating the prototype eVTOL batteries can help them rapidly discharge their leftover energy, so they can then quickly recharge.

“Our self-heating technique has a heating speed of 1 to 5 degrees Celsius per second and consumes only 0.8 percent battery energy for every 10 degree Celsius temperature rise,” Wang says. “At the same time, the embedded nickel foil adds less than 1.5 percent weight and volume and less than 0.3 percent cost to a baseline battery.”

It took Wang and his colleagues about 10 years from stumbling upon the idea of heating batteries “to demonstrating and perfecting it to various battery prototypes today,” he says. A great challenge they faced was reducing the complexity of these self-heating structures as much as possible—“simplicity is our most complicated task,” he adds.

The researchers are now applying their strategy to battery chemistries with even greater energy densities. With the next generation of batteries they are developing, they aim to achieve 350 to 400 watt-hour per kilogram energy densities and reduce costs to US $50 per kilowatt-hour while keeping charging times of five to 10 minutes.

“This second generation will enable not only commercial fleet eVTOLs like flying taxis, but also privately owned flying cars,” Wang says. “My dream is to drive a flying car to work before I retire.”

The scientists detailed their findings June 7 in the journal Joule.

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.