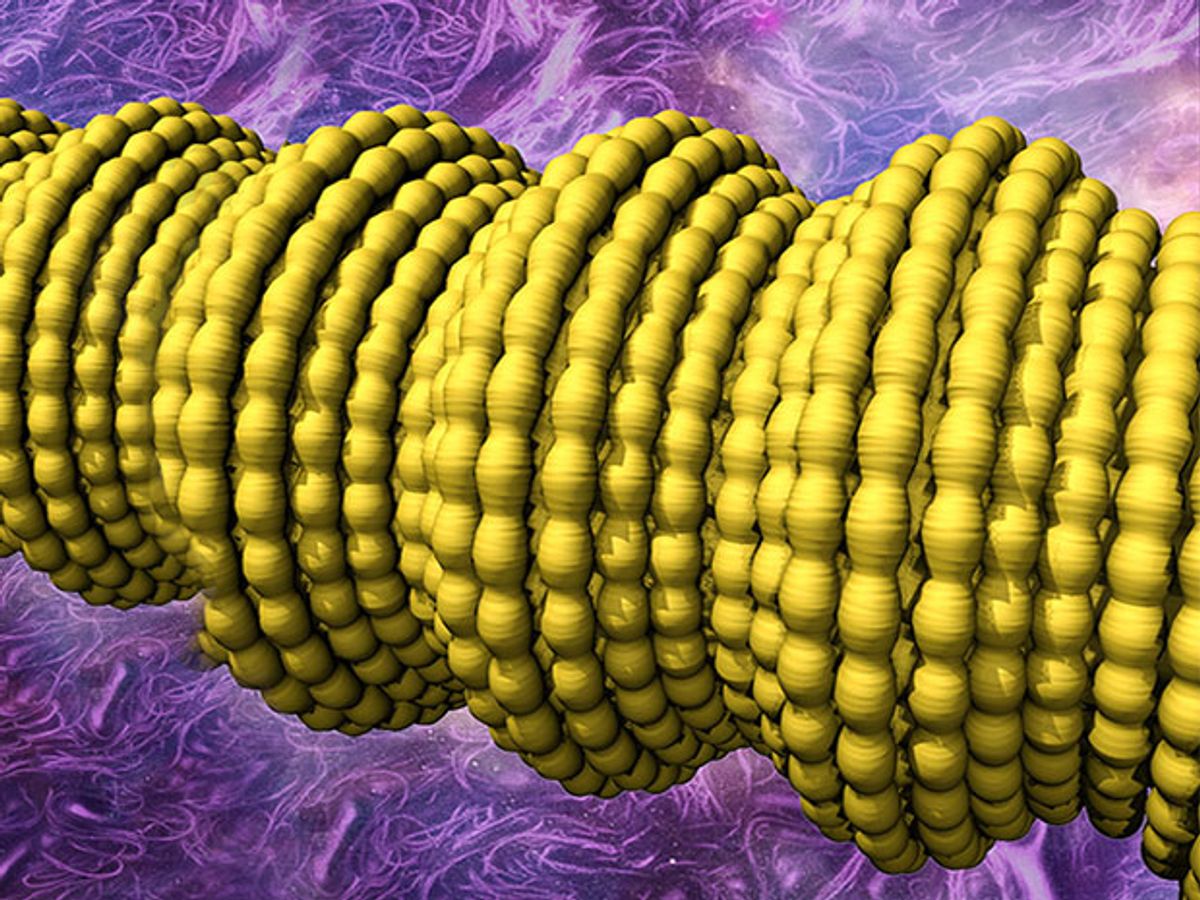

The list of potential applications for a new electrically conducting fiber—artificial muscles, exoskeletons and morphing aircraft—sounds like something out of science fiction or a comic book. With a list like that, it’s got to be a pretty special fiber… and it is. The fiber, made from sheets of carbon nanotubes wrapped around a rubber core, can be stretched to 14 times its original length and actually increase its electrical conductivity while being stretched, without losing any of its resistance.

An international research team based at the University of Texas at Dallas initially targeted the new super fiber for artificial muscles and for capacitors whose storage capacity increases tenfold when the fiber is stretched. However, the researchers believe that the material could be used as interconnects in flexible electronics and a host of other related applications.

In research published in the journal Science, the team describes how they devised a method for wrapping electrically conductive sheets of carbon nanotubes around the rubber core in such a way that the fiber's resistance doesn’t change when stretched, but its conductivity increases.

You can watch a demonstration in the video below:

“We make the inelastic carbon nanotube sheaths of our sheath-core fibers super stretchable by modulating large buckles with small buckles, so that the elongation of both buckle types can contribute to elasticity, said Ray Baughman, senior author of the paper and director of the Alan G. MacDiarmid NanoTech Institute at UT Dallas, in a press release. “These amazing fibers maintain the same electrical resistance, even when stretched by giant amounts, because electrons can travel over such a hierarchically buckled sheath as easily as they can traverse a straight sheath.”

The researchers have also been able to add a thin coat of rubber to the sheath-core fibers and then another carbon nanotube sheath to create strain sensors and artificial muscles. In this setup, the buckled nanotube sheets act as electrodes and the thin rubber coating serves as the dielectric. Voilà! You have a fiber capacitor.

“This technology could be well-suited for rapid commercialization,” said Raquel Ovalle-Robles, one of the paper’s authors, in the press release. “The rubber cores used for these sheath-core fibers are inexpensive and readily available. The only exotic component is the carbon nanotube aerogel sheet used for the fiber sheath.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.