As useful as robot arms are, they tend to be heavy, bulky things that need a bunch of support and structure to get them to work properly. If you need precision and speed, this may be unavoidable, but if all you’re looking for is long reach, a high-strength to weight ratio, and very low cost (which, admittedly, are a lot of things to be looking for), another option was presented at ICRA today by researchers from the University of Pennsylvania: an arm made out of a strip of plastic that zips together with itself, creating an extendable cylinder that can be paired with winches and cables and used for manipulation.

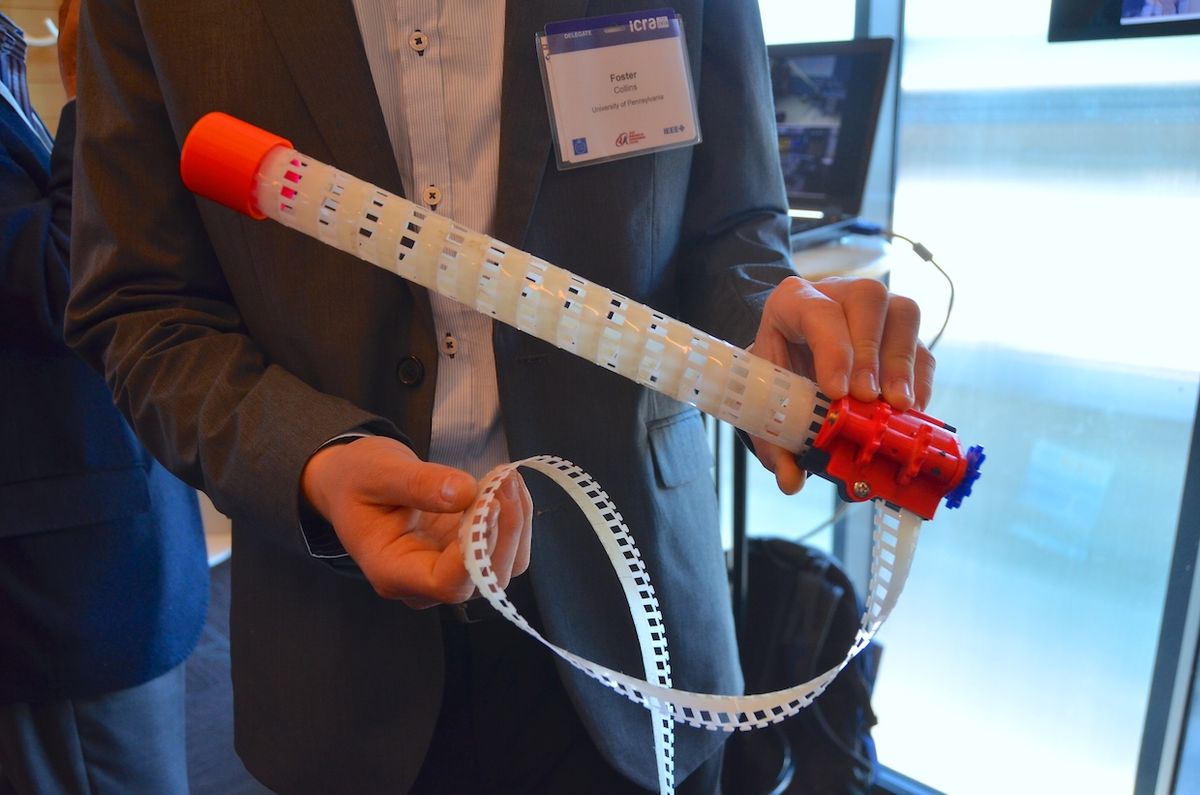

This concept is similar in principle to some commercially available systems like the Zippermast and Spiralift, but both of those designs are heavier and significantly more complicated. The spiral zipper uses a single band that’s made of very lightweight plastic, with a relatively simple meshing mechanism that meshes the teeth on the bottom edge of one wrap with the teeth on the top of the wrap below to create a cylinder that has a very high strength to weight ratio, with exceptionally good compressive performance. And changing the length of the arm is as simple as zipping or unzipping the band: it’s completely reversible, and you can stow the arm almost entirely in a very small volume consisting of the plastic band spooled around the zipping mechanism.

The spiral zipper only creates the structure of the arm: there’s no integrated actuation, besides the extension and retraction that you get from zipping or unzipping the arm on demand. The researchers envision mounting the base of the arm on a gimbal, with a 3-DoF wrist on the end of it, to create a 6-DoF system. Since the arm isn’t particularly stiff (especially when moving), it doesn’t make sense to actuate it with motors from the base. Instead, winches mounted on the base with tethers connected to the end of the arm could be used to control its motion, which makes sure that the predominant force on the tube is compression (what the structure is good at).

In terms of applications, there’s a lot of potential for a system with such a high strength to weight ratio that can pack down into a very small size. For example, the U.S. Army is interested in mounting the arm on an octorotor being developed at the Army Research Laboratory, and the researchers are also planning on trying the arm out on indoor mobile robots as aids for the elderly. The arm could also “enable the manipulation of large objects such as furniture,” and at ICRA we saw some pictures of a prototype climbing robot that can hoist itself up by varying its arm length. It also seems like this design would lend itself to space applications, where efficiency in weight and volume are such a priority. It’s a very clever idea, and we’re looking forward to seeing what UPenn does with it.

“Design of a Spherical Robot Arm With the Spiral Zipper Prismatic Joint,” by Foster Collins and Mark Yim from the GRASP Lab at the University of Pennsylvania, was presented this week at ICRA 2016 in Stockholm, Sweden.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.