A new way of coaxing light out of an organic LED may make for cheaper displays and could even provide a way to see magnetic fields.

By choosing a molecule of a particular shape, a team of German and American researchers designed a new type of OLED that has the potential to emit as much light as a commercial OLED, but without the rare metals normally added to make the devices efficient. If manufacturers could leave out metals such as iridium or platinum, they might not have to worry about potential shortages of these elements. This would allow them to bring down the costs of OLEDs, which are increasingly being used in the screens of smartphones and televisions, as well as in solid-state lighting.

OLEDs convert only a fraction of the electrical current they receive into light. That’s because of a quantum mechanical property of the electrons and their positive quasiparticle counterpart holes, called spin. Spin is what gives rise to magnetism; when the spins of a majority of electrons in a material point in the same direction, the material is magnetic. Each electron and each hole can exist in one of two spin states, so when they pair up there are four possible states, three of which dissipate their energy as heat rather than light. This means that only a quarter of the electricity put into the device produces light. OLED makers add metal to the hydrocarbon molecules in their devices to mix up the spin states and increase the number of light-generating combinations.

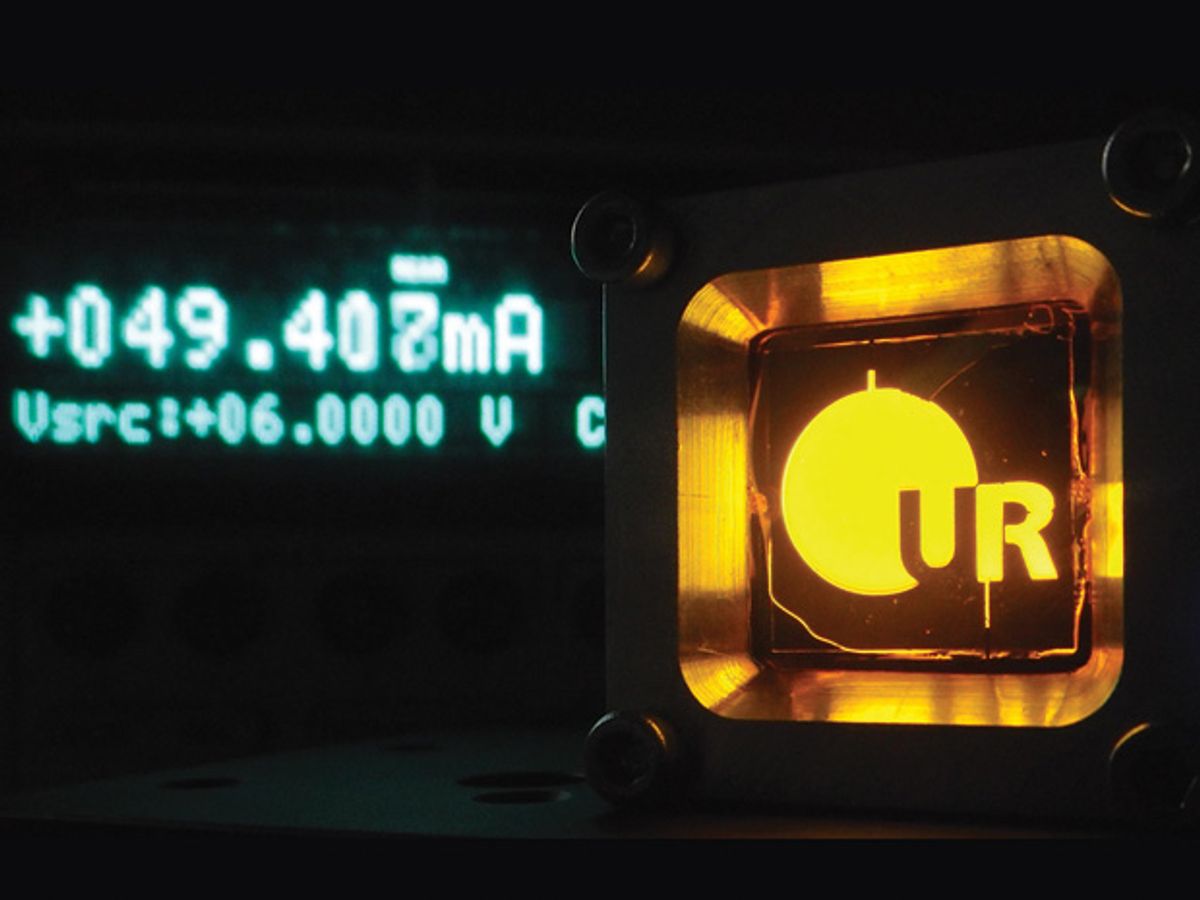

But it’s also possible for some of the spins to switch to the more light-friendly version on their own, says John Lupton, a physicist at the University of Regensburg, in Germany, who was part of the team that did the work. “You just have to wait long enough for this spin state to spontaneously relax,” he says.

If an electron-hole pair can be held in its electrically excited state long enough for one spin to flip, when it drops to a lower energy state it’ll emit the extra energy as a photon rather than as heat, Lupton explains. “Long enough” is measured in milliseconds, compared with the nanoseconds it usually takes for emission to occur, a difference of six orders of magnitude.

The trick, which the researchers from Regensburg, the University of Bonn, the University of Utah, and MIT explain in a paper published online by Angewandte Chemie, lies in the shape of the organic molecules used in the LED. The researchers developed two kinds of polycyclic aromatic hydrocarbons (carbon-based molecules having multiple ring-shaped components): one called phenazine and the other triphenylene. The atomic structures of the molecules were such that they trapped the charge carriers long enough for the spontaneous change to occur. A peculiarity of the molecule–the researchers speculate that it may have to do with different energy characteristics in different areas of the molecule–prevents the extra energy from being released as heat before the spin can flip. “Because of their shape, you can localize the electron density and therefore the spin density in specific areas in the molecules,” Lupton says, adding that the result was surprising to the researchers, who were actually studying other facets of OLEDs. “If you look at textbooks of physical chemistry, this should not have actually worked,” he says.

Last year another group, led by Chihaya Adachi at Kyushu University, in Japan, demonstrated its own method for making OLEDs without the use of metal. The researchers designed a molecule that relies on fluorescence for light emission, instead of the phosphorescence used in most metal-reliant OLEDs. Their mechanism, called thermally activated delayed fluorescence, takes the heat released by some of the charge carriers and uses it to bump up the energy level of others to the point that they emit light instead of heat when they relax. The Kyushu scientists say their material has an internal efficiency of nearly 100 percent, which translates into about 14 percent of the electricity pumped into the OLED reemerging as light, compared with about 20 percent in commercial OLEDs that use metal.

Alán Aspuru-Guzik, a chemist at Harvard, sees the work by Adachi and Lupton as developments “that could lead to a breakthrough in the field of OLEDs.” The work both groups are doing could lead to better emission in the blue end of the spectrum in particular. Blue organic light emitters have been the most difficult to develop.

At the moment, the price of rare metals needed in OLED manufacturing is so low that manufacturers are unlikely to need either trick soon. And this new method doesn’t actually improve OLED efficiency over what existing devices can deliver, says Lupton. But it could prove appealing to OLED manufacturers if the price of iridium goes up.

Far more interesting may be another aspect of Lupton’s discovery: The spins of the charge carriers in this type of OLED control the wavelength of the light emitted. “You can actually measure the spin of the electron within your OLED by using the color,” Lupton says. And because spin on the quantum level translates into magnetism in the macro world, “if you design this in the right way you could make it incredibly sensitive to magnetic fields,” Lupton says. “That will actually allow us to use the color of the OLED as a compass.” He says such a device could be more sensitive than Hall effect devices, which are common in smartphone navigation systems and in automobiles, where they measure the rotation of the wheels.

The research might even provide a new clue to how birds navigate using Earth’s magnetic field. While the exact mechanism is still debated, some scientists suspect that their eyes let them see shifts in the field as subtle variations of color. Lupton says they may be sensitive to color changes caused by alterations in the spins of electrons.

Neil Savage is a freelance science and technology writer based in Lowell, Mass., and a frequent contributor to IEEE Spectrum. His topics of interest include photonics, physics, computing, materials science, and semiconductors. His most recent article, “Tiny Satellites Could Distribute Quantum Keys,” describes an experiment in which cryptographic keys were distributed from satellites released from the International Space Station. He serves on the steering committee of New England Science Writers.