Ziggy Stardust would love this: Spiders could help find life on Mars.

That is, optical sensors made with spider silk could be used to look for trace gases produced by biological processes, according to a researcher who showed how silk could be used in place of conventional optical fibers, under a grant from the European Space Agency. The scientists hunting for life on Mars would like to be able to test for small amounts of ammonia, which might be emitted by the metabolism of microbes, so they need a sensor that can detect that while remaining insensitive to the large amounts of carbon dioxide in the Martian atmosphere.

Spider silk does the trick, says Luc Thévanaz, who heads a research group studying fiber optics and optical sensing at Swiss Federal Institute of Technology of Lausanne. The fiber can carry a beam of light, and when something in the environment affects the fiber, that alters some characteristic of the light beam. The concept is used in strain sensing for bridges and other large structures: If the fiber stretches, it changes the spacing of an optical grating inside, altering the wavelength of the light passing through and alerting monitors to the amount of strain.

But conventional optical fibers, made of silica glass, are chemically inert, making them poor chemical sensors. On the other hand, Thévanaz says, “the optical properties of the silk are massively modified by chemicals.” The presence of certain molecules causes hydrogen bonds in the silk molecules to break, and the result is a change in the polarization of light passing through. This only works, though, on polar molecules, such as ammonia, which have unequal charges on each end. Non-polar molecules, such as CO2, cause no response.

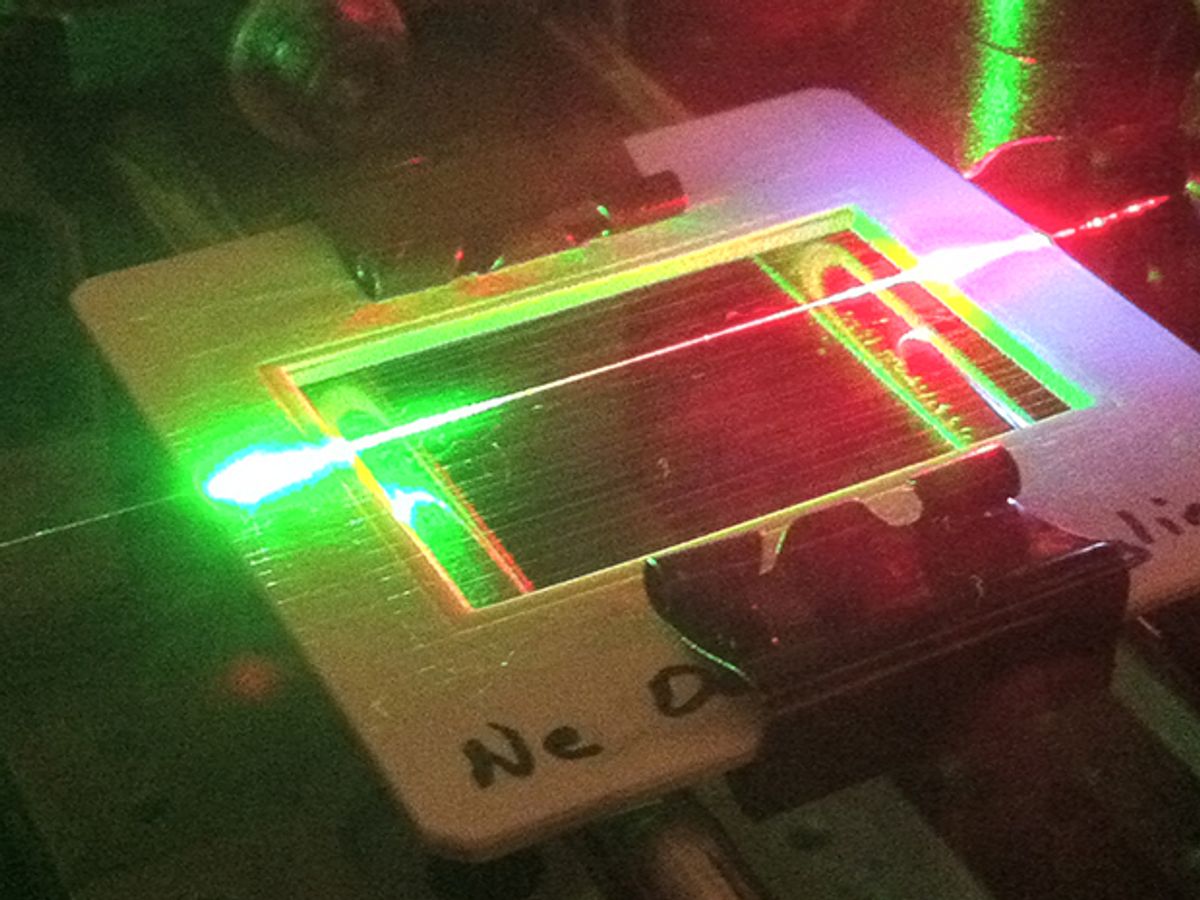

Thévanaz and his team tested their concept using the silk dragline from a female Nephila edulis spider. They found they could get good light transmission from the visible to the infrared, up to wavelengths of about 1400 nm. Their best transmission was infrared light at 900 nm, which had optical loss of 4 dB/cm, a measure of how far the light can travel before being absorbed by the material. While that’s orders of magnitude higher than the loss in silica, which can be as low as 0.2 dB/km, it’s sufficient for sensing applications. “Silk is extremely transparent, though far less transparent than glass,” Thévanaz says. “Loss is not a big problem because over a few centimeters we have an extremely sensitive response.”

For more down-to-earth applications, these silk fiber sensors might be useful for monitoring industrial processes or as sensors in automobiles, because they shouldn’t need to be periodically replaced like sensors that rely on irreversible chemical reactions, Thévanaz says. He’s hoping to build up a library of measurements showing which changes in the light beam correspond to particular chemicals. And he says the process can be improved with the use of artificial silk, or by doping the silk with other chemicals to alter what it’s sensitive to.

Neil Savage is a freelance science and technology writer based in Lowell, Mass., and a frequent contributor to IEEE Spectrum. His topics of interest include photonics, physics, computing, materials science, and semiconductors. His most recent article, “Tiny Satellites Could Distribute Quantum Keys,” describes an experiment in which cryptographic keys were distributed from satellites released from the International Space Station. He serves on the steering committee of New England Science Writers.