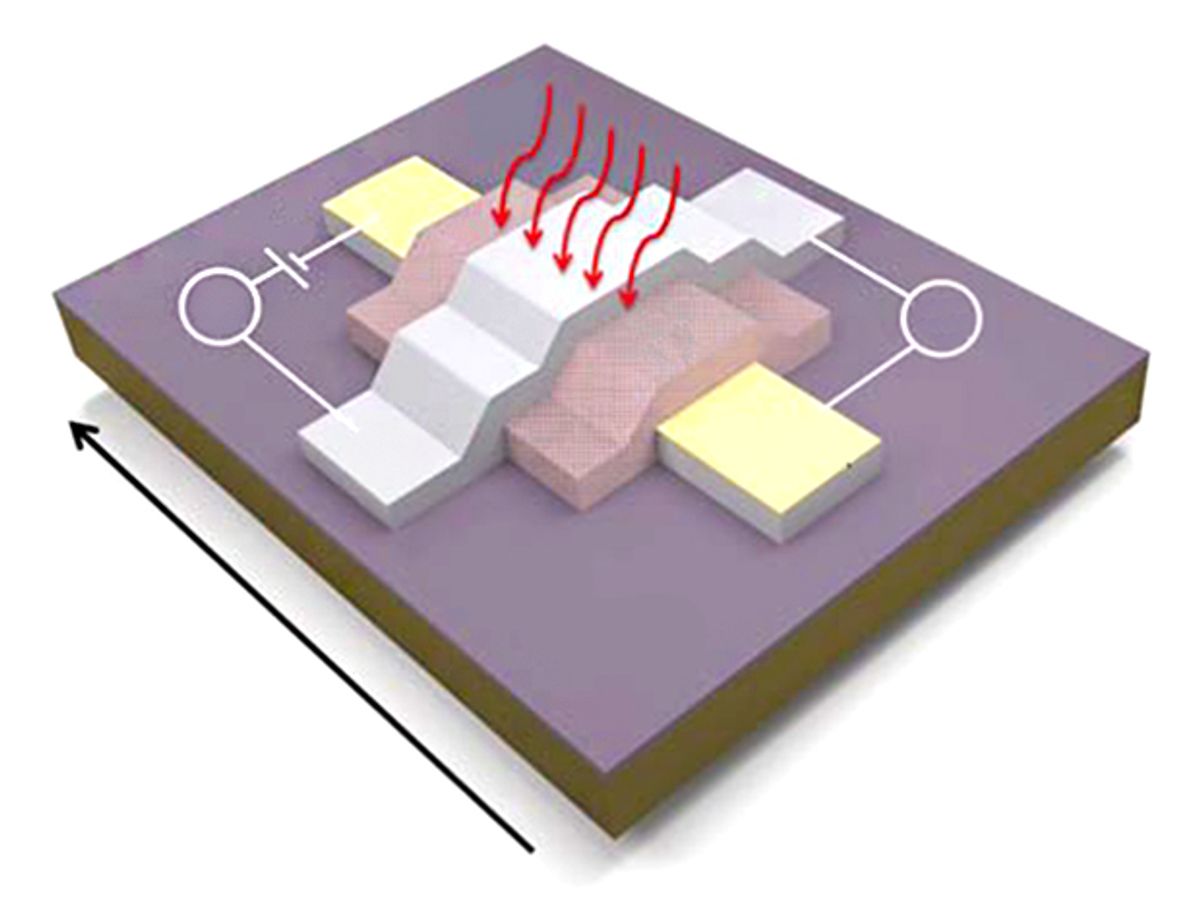

An international team of researchers has developed a photovoltaic cell based on a combination of magnetic electrodes and C60 fullerenes— sometimes referred to as Buckyballs—that increases the photovoltaic efficiency of their device by 14 percent over photovoltaics using ordinary materials and architecture.

In research described in the journal Science, scientists from China, Germany, and Spain have taken spin valves—devices based on giant magnetoresistance and used in magnetic memory and sensors—and combined them with photovoltaic materials. The result offers a new way for solar cells to convert light into electricity.

“The device is simply a photovoltaic cell,” says Luis Hueso, research professor and leader of the Nanodevices Group at CIC nanoGUNE in Spain, in an e-mail interview with IEEE Spectrum. “However, we are using magnetic electrodes (cobalt and nickel-iron) rather than standard indium tin oxide (ITO) and aluminum as commonly used in organic photovoltaics.” The magnetic electrodes provide electrons with a certain orientation of their spin, creating what’s called a spin polarized current. Using these electrodes increased the photovoltaic efficiency by 14 percent compared to using ordinary electrodes, he says.

In order to achieve these results, the researchers needed the device to have both a photovoltaic effect and a spin transport effect. That is, the electrons keep their spin orientation as they cross the device, according to Hueso. “These two effects have not been observed before in the same device, only separately,” Hueso adds.

One of the byproducts of these simultaneous photovoltaic and spin-polarized effects is that the device they have developed has the added functionality of serving as an inverter, which is used to convert the direct current (DC) produced by solar cells into alternating current (AC).

Hueso explains that the current inversion is created by an external magnetic field. As the magnetic field changes, the current changes direction. The reason this works is that the current inside the device has two sources: one is the current generated by the light and the other is the current coming from the magnetic electrodes.

The current generated by the light can be changed by the amount of light irradiation. The current coming from the electrodes can be changed by the magnetic field. Balancing both contributions means the flow direction of the overall current can be modified.

The key to the functioning of the device is the C60 fullerene. The C60 is both a photovoltaic material and one that can sustain the spin polarization of the electronic carriers. “Since both effects had been demonstrated in the past—the spin one by our group—we decided to use it for a proof-of-principle experiment,” says Hueso.

The actual current output in the device is fairly small, mainly due to the fact that the C60 is not an great material for photovoltaics. To address this the researchers are currently working on building a similar device using better performing materials.

While Hueso recognizes more engineering would need to be done with the device they have produced, he believes that an actual device that acts as both a photovoltaic and an inverter could indeed be possible.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.