Smart Sensors

New standard could save lives and money

Chances are, your health and happiness rely on sensors, those ubiquitous little devices that tell us if a fridge is too cold, a nuclear reactor’s safety systems are operating, or a factory production line is processing components correctly. But sensors have a dirty little secret: it’s all too easy for them be in perfect working order, reporting all is well when, in fact, your milk is turning into a frozen block, the reactor’s safety system is impotent, and that factory has filled a warehouse with useless—and possibly dangerous—products.

Fortunately, help is on the way with a new standard for analog sensors, the most common kind in use today. The dirty little secret of sensors is calibration, the process by which data from a sensor are mapped to real-world conditions, and the new standard should help make miscalibration a thing of the past. Miscalibrated sensors can cause problems ranging in severity from a wasted morning’s research to what happened at the Bruce B nuclear generating station near Toronto in 2002. There it was discovered that a backup reactor shutdown system that had been operating for weeks, in what appeared to be working order, was actually incapable of catching a dangerous rise in radiation, owing to an incorrectly calibrated neutron detector.

Like most standards, the new standard goes by an unlovely name—in this case, IEEE 1451.4. But 1451.4 marks a huge advance in sensor technology and is already being applied in research and industrial laboratories. This new standard marries the tried-and-true robustness and cost-effectiveness of analog sensors with the intelligence of digital equipment. Now, what does that mean in practice? A lot of things—in the long term, one of the most important aspects of 1451.4 is that it offers a standard interface and protocol by which a sensor can describe itself over a network. With the advent and adoption of intelligent networked and wireless sensors, the notion of self-identifying devices may seem fairly elementary, but this has taken more than a decade to happen with analog sensors. Most commercially available sensor networks today are based on proprietary communications protocols, limiting their usefulness and hampering their adoption. IEEE 1451.4 could change all that.

We’ll return to the long-term promise of 1451.4, but for now let’s stay with the immediate problem of calibration. IEEE 1451.4 will eradicate one of the most common sources of sensor errors today: incorrectly transcribed calibration information from sensor data sheets. To understand how these errors arise and why they’re such a big problem, look at how sensors are traditionally used. Analog sensors typically output a voltage that is proportional to the magnitude of whatever it is they’ve been designed to measure—be it temperature, pressure, or something more exotic.

Analog sensors persist in a digital world because they are cheap, extremely reliable, and rugged. Simply put, they can take a beating that would damage or destroy a digital sensor that can output a number describing the measured quantity directly. And punishing environments—such as the inside of a car engine or the depths of an oil well—are often exactly the places where we most want to put sensors.

Although analog sensors are easy to hook up to a data acquisition system that monitors output voltage, converting that voltage back into degrees Celsius, pascals, or whatever else, is trickier. In other words, when a temperature sensor registers 2.5 volts, we need to know how to translate that voltage into the actual temperature, be it 100°C, 50°C, or 2500°C [see illustration, "Curve Confusion"].

Until now, the only way to know was by looking up the sensor’s data sheet, a manufacturer-supplied document that details how to calibrate the sensor correctly. Someone has to enter information from this sheet into the data acquisition system, which is usually based on a personal computer. A single moment of human error here can make a sensor—and all the data it gathers—worse than worthless.

This was the impetus for the 1451.4 standard, developed by the IEEE in conjunction with companies such as Aeptec Microsystems, Bruel & Kjaer, Crossbow Technology, and my company, National Instruments Corp., as well as the National Institute of Standards and Technology and the U.S. Air Force, among others. The standard is built around the concept of the Transducer Electronic Data Sheet, or TEDS.

A TEDS describes the sensor’s electrical interface requirements—how the data acquisition hardware needs to be configured to read the sensor properly—and tells the acquisition system how to scale analog output voltages properly into the units that correspond to the physical property being measured, such as degrees Celsius. By doing this automatically, in one swoop, a 1451.4-compliant device eliminates the possibility of human error in transcribing the data sheet.

The heart of 1451.4 is the use of a digital read-only memory (ROM) chip embedded in the analog sensor that stores the sensor’s electronic data sheet, as well as information identifying the sensor—namely, its type, manufacturer, and a serial number. When hooked up to a 1451.4-enabled data acquisition system, the ROM chip transmits the TEDS to the system, in a way similar to a USB mouse or printer identifying itself to a PC after it is plugged in.

The standard, however, importantly, does not dictate where the relatively delicate ROM chip should be placed in relation to the tougher analog sensing element. The chip can be added inside the sensor housing, in the sensor connector that attaches to the data acquisition equipment, or even inside the sensor cable. This allows the analog sensor itself to still be placed in harsh environments, with the ROM chip located in the usually more benign environment at the other end of the sensor cable.

To see how powerful 1451.4 is, consider the problem faced by the state of Ohio, which has to build and maintain roadways that must endure extreme winter conditions. To research the durability of the materials used in road construction, the Ohio Research Institute for Transportation and the Environment at Ohio University, in Athens, studies the performance of pavements by embedding sensors in roadways. Analog sensors measure strain, load, and deflection in the pavement. Because of the environmental conditions and cost constraints, permanent data acquisition systems and all-digital sensors were impractical. Instead, the Ohio team decided to use a portable data acquisition system that could be transported to each of the monitoring sites and hooked up to the permanently embedded sensors.

One of the greatest challenges of the project occurs when the portable system arrives at a site. The embedded sensors have to be connected to the system to conduct a test, but with the sensors embedded in a roadway, how can the team keep track of which cable belongs to which sensor? You could write out a paper or card tag for each cable, but as researchers soon discovered, even though the ends of the cables terminated in a protective box at the side of the road, mice get in and eat the tags. You could write directly on the cables, but the rodents have a taste for PVC insulation too, and nibble at the writing. Color-coded cables might work—except the dye in the colored insulation leaches out in the salty runoff from an Ohio highway over the winter, so a red, black, and white set of cables will be white, white, and white by the time the team returns. Metal tags do work, but making them is time-consuming and costly.

To combat the problem, the Ohioans are developing a 1451.4-based system that will automatically identify which sensor is at the end of each soggy, mice-gnawed cable. They have successfully demonstrated the system in Ohio University’s indoor pavement testing facility, and when the team next gets permission to tear up the highway and install new sensors in 2007, those sensors will be 1451.4-enabled.

Even if you can’t install new sensors, 1451.4 may still be able to help. The standard also establishes the concept of “virtual TEDS.” It allows 1451.4-enabled data acquisition systems to download correct calibration information for the billions of legacy analog sensors already in place that don’t have built-in TEDS chips (just as long as someone has created a virtual TEDS for the sensor). An entire database of TEDS files for tens to millions of sensors can be stored on a disk or on a server accessible over the Internet. A unique ID number, sorted by vendor and model or serial number, identifies each TEDS.

John Deere, a major manufacturer of agricultural, construction, and forestry equipment, has a product engineering center in Waterloo, Iowa, where engineers are planning to use virtual TEDS to deal with legacy sensors. The center uses sensors for measuring such items as temperature and pressure inside new vehicle transmissions. The test center’s goal is to calibrate every sensor in a central laboratory and then tag each one with a unique identification number. The calibration information will be uploaded into a database in the virtual TEDS format. Then the sensor will be dispatched to product-testing facilities, where technicians will use the ID number to download the matching calibration information. This would then be used by 1451.4-enabled software and hardware made by National Instruments, of Austin, Texas, to automatically configure the data acquisition equipment for the sensor, improving the quality of data and reducing the number of repeat test runs.

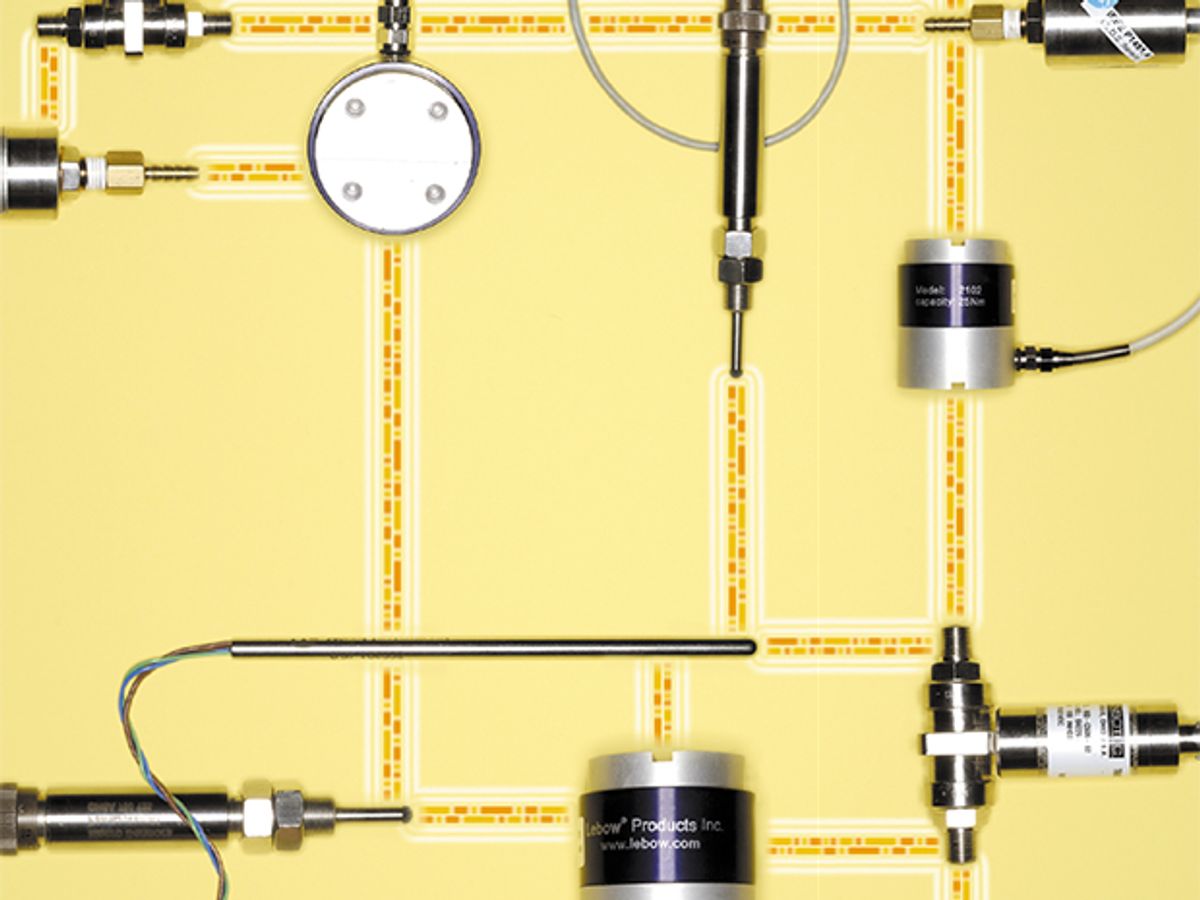

Beyond TEDS and these early applications in Ohio and Iowa, 1451.4 could have a vast number of uses. As mentioned earlier, the digital smarts given to analog sensors by 1451.4 will allow them to be easily integrated into networks. Networked sensors today cannot normally communicate with other devices or systems outside of their proprietary networks. But coupled with related IEEE standards that describe how data should be transmitted over wired and wireless networks, it should be possible to easily monitor 1451.4-enabled sensors over almost any network. This integration could encompass a variety of operating platforms for data acquisition, storage, and visualization, including, for example, devices such as PDAs [see illustration, "Plug and Play"].

To see the advantages of this technology, imagine you were transporting a crate of wine by sea. Currently, only a handful of thermostats—at most—control the temperature of an entire cargo hold, and uneven heating or cooling can mean that some cargo is exposed to inappropriate temperatures. A humidity and temperature sensor in the shipping crate could monitor the temperature of the wine, and through a wireless network in the ship's hold, alert the ship's HVAC system if the wine were in danger of overheating or freezing.

Once the ship arrived at port, the crate's serial number would allow a receiving dock to register and identify it automatically during unloading. The dock could also download the history of the wine's reported conditions from the ship's computer. The same crate sensor could communicate with the truck used to transport the wine to the warehouse. Any potential purchaser could get a complete record of the wine's storage conditions, reducing the risk of buying something spoiled or damaged.

Or imagine a series of sensors spread throughout a “smart building” that could be used to control environmental systems more efficiently, or even warn of structural problems [see “Smart Buildings,” IEEE Spectrum, August 2003]. When the building is modified or renovated, new sensors could be integrated seamlessly with the existing system.

Back in the present day, a consortium of more than two dozen sensor, instrumentation, and software vendors has been created to promote the implementation of IEEE 1451.4 into their products. Already, some sensor types are now more common with TEDS than without, and several hardware and software platforms including National Instruments' LabVIEW are available to read and write TEDS data. And as new digital and communication technologies are introduced, they will incorporate TEDS, making possible the kind of pervasive smart sensor networks of tomorrow that technological visionaries have predicted [see “We Like To Watch,” Spectrum, July 2004], and the kind of ubiquitous calibration errors that plague us now could become a thing of the past.

About the Author

Brian Betts, a data acquisition technical marketing group manager for National Instruments Corp., in Austin, Texas, leads the execution and development of launches of PC-based data acquisition, signal conditioning, and software products.