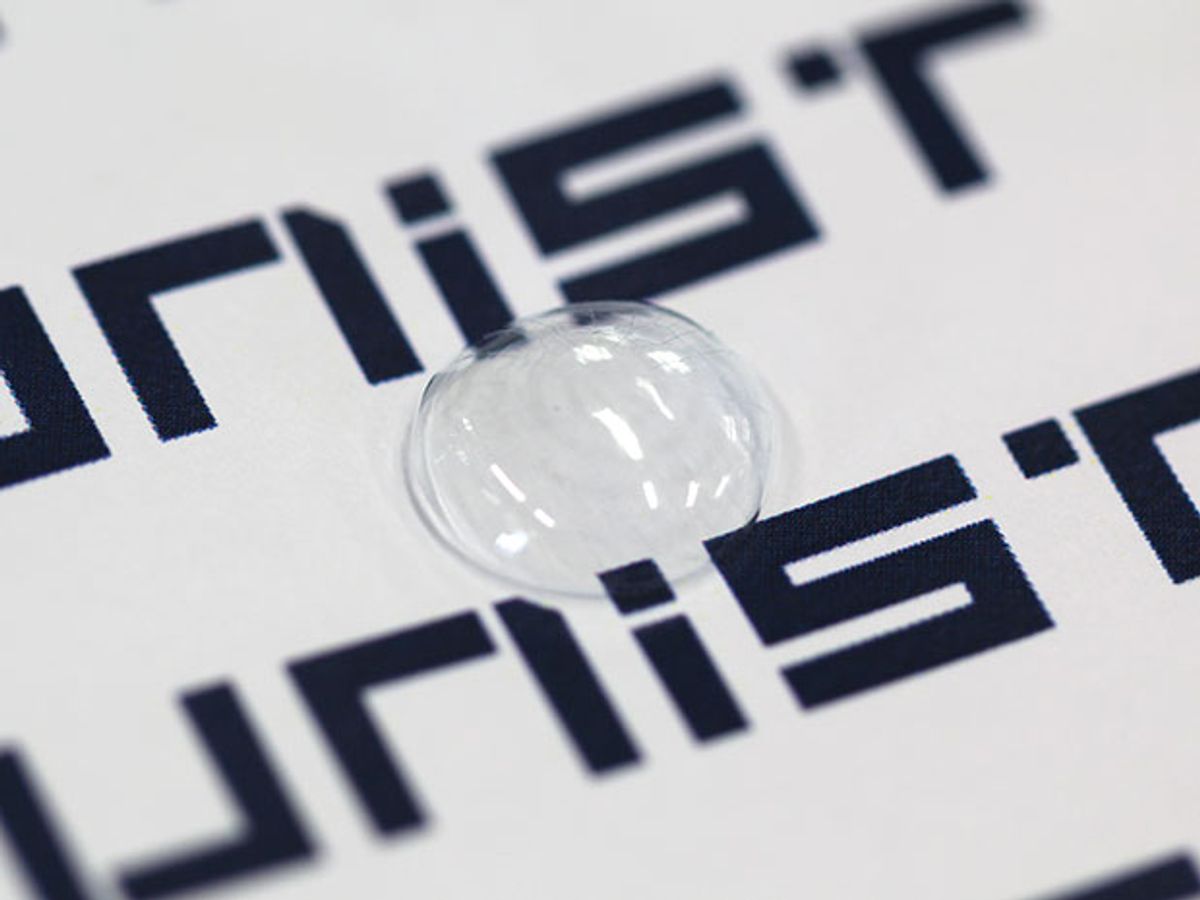

While tech giant Google continues to struggle to make a contact lens for monitoring diabetes, researchers at Ulsan National Institute of Science and Technology (UNIST) in South Korea have offered up at least one part of the puzzle: better wearability. Through the use of a hybrid film made from graphene and silver nanowires, the UNIST researchers have made contact lenses for detecting multiple biomarkers that are clear and flexible.

In research described in the journal Nature Communications, the UNIST researchers used graphene-nanowire hybrid films to serve as conducting, transparent, and stretchable electrodes. While the hybrid film alone does not perform any detection, the electrodes do ensure that the electrodes in the contact lenses don’t obscure vision and that they’re flexible enough to make wearing the lenses comfortable.

In addition to offering better transparency and comfort, the contact lenses developed by the UNIST researchers depart from previous contact lens sensors in that they’re able to detect multiple biomarkers. This contact lens should be able to pick up indictors for intraocular pressure, diabetes mellitus, and other health conditions, according to the researchers.

To detect intraocular pressure, a dielectric layer is sandwiched between two hybrid films. In this arrangement, the films now become a capacitor that responds to intraocular pressure. At high intraocular pressure, the thickness of the dielectric layer decreases, resulting in the increased capacitance. High intraocular pressure also increases the inductance of the antenna coil by bi-axial lateral expansion.

For detecting glucose, the top hybrid film layer is exposed to tears and detects glucose. In a selected region of the film, the researchers removed the nanowires so only graphene remained. The surface of graphene was then coated with an enzyme that binds selectively to glucose. This binding changes the resistance of the graphene.

The changes of resistance, inductance and capacitance in these two detection modes can be monitored wirelessly in real-time.

One of the challenging aspects of the research was the glucose sensor, according to the researchers. “In tears, there are many interfering ions and molecules that potentially cause false positive responses,” explained Chang Young Lee, an assistant professor at UNIST and co-author of the study, in an email interview with IEEE Spectrum. “We need to test the selectivity and long-term reliability of the glucose sensor. The effort includes designing and finding a molecule that selectively binds to glucose, which is another large research area.”

Lee envisions this research as a novel platform that will enable integration of glucose sensor onto a soft contact lens. “Measuring the glucose accurately and reliably is another large research area,” Lee added. “A good glucose sensor developed by another researcher, for example, can easily be integrated onto our platform.”

In this novel platform, both the graphene and the silver nanowires contribute indispensible properties. The silver nanowires offer a one-dimensional (1D) conducting material, and by creating a network (mesh) of it, it’s possible to make a transparent, conducting, and flexible film. However, the film made of silver nanowires alone has limitations, such as high contact resistance at the nanowire-nanowire junctions, low breakdown voltages, poor adhesion to flexible substrates, and oxidation in harsh environments.

This is where the two-dimensional (2D) graphene comes in, with its properties of being highly transparent, conducting and flexible. By creating a hybrid structure of graphene and nanowires, the limitations of the nanowires are overcome. “The key is in the hybrid of 1D and 2D structures,” added Lee.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.