Engineers at the University of Texas Austin have developed what they claim is the smallest, fastest spinning and longest lasting nanomotor built to date. The engineers have demonstrated that their nanomotor is capable of rotating for 15 continuous hours at a speed of 18 000 rpm. These performance figures are on an entirely different scale to those of similar nanomotors that run anywhere from 14 rpm to 500 rpm and have only rotated for a few seconds or minutes.

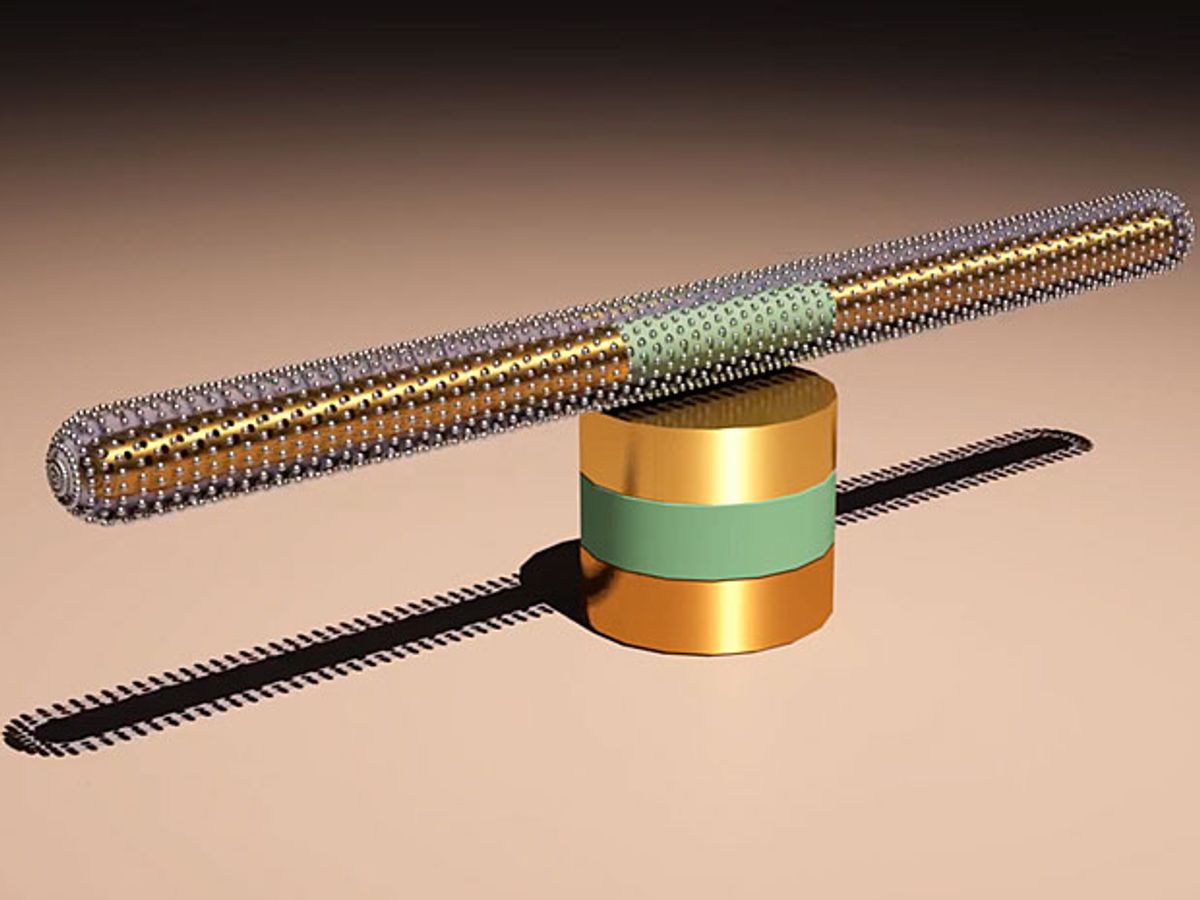

The nanomotors, which are described in the journal Nature Communications, were built in a bottom-up manufacturing technique in which nanowires serve as rotors, patterned nanomagnets are the bearings, and quadrupole microelectrodes act as stators.

The entire structure of the nanomotor is smaller than 1 square micrometer, which means it is conceivable that they could fit inside some living cells. The nanomotors are also capable of rapidly mixing and pumping biochemicals as well as moving through liquids.

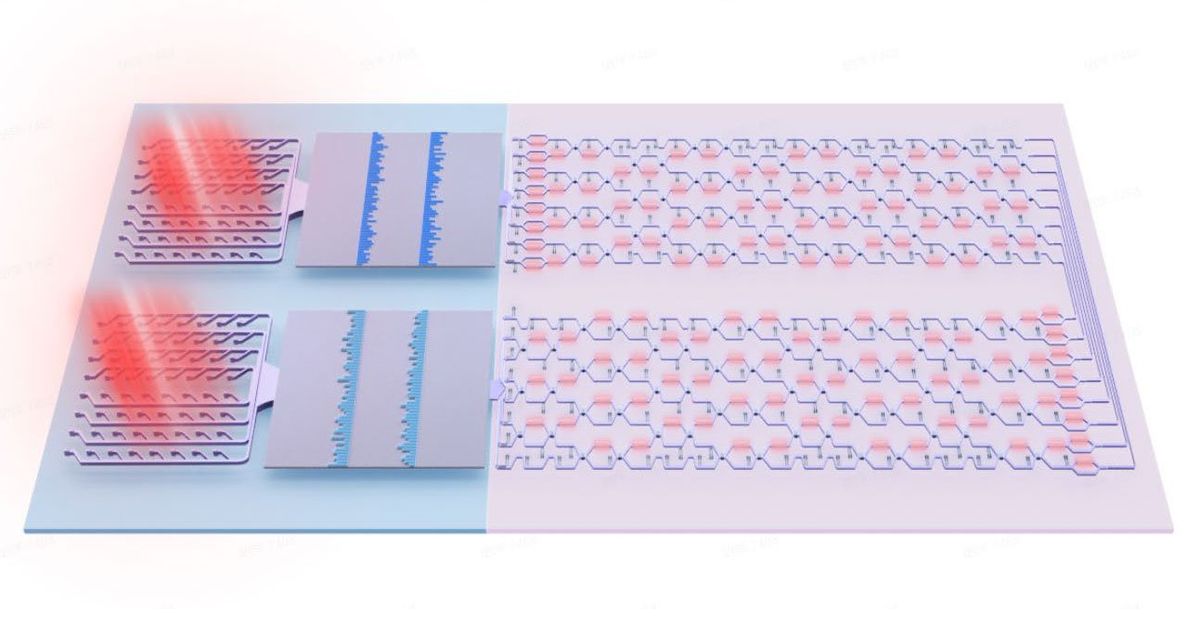

The researchers coated the nanomotors with a biochemical and started spinning them. They discovered by controlling the spin of the nanomotors they could manage how the biochemical was released. This could prove an effective tool in drug delivery inside the body, they claim.

"We were able to establish and control the molecule release rate by mechanical rotation, which means our nanomotor is the first of its kind for controlling the release of drugs from the surface of nanoparticles," said Mechanical engineering assistant professor Donglei "Emma" Fan in a press release. "We believe it will help advance the study of drug delivery and cell-to-cell communications."

The researchers were able to control the spin of the nanomotors using a technique developed by Fan in which AC and DC electric fields were used to turn the motor on and off and propel the rotation either clockwise or counterclockwise. With this technique, the researchers found that they could position the nanomotors in a pattern and move them in a synchronized fashion.

In the video below, you can see an animation of how the nanomotors operate and how they could deliver biochemicals.

Earlier this year, researchers at Penn State University demonstrated that a nanomotor could be placed inside human cells and have their movements controlled through the use of both ultrasonic waves and magnetic forces. Because one of the envisioned applications for that work was to have the nanomotor spin inside cancer cells to destroy them, perhaps with this high-rpm nanomotor the destruction would be faster and more complete.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.