Using human skin as one of its charge-collectors, a new flexible generator converts muscle movements into enough power for small electronics. The postage-stamp-sized device takes advantage of static electricity to convert mechanical energy into electrical energy.

Such friction-powered generators could usher new types of wearable sensors that don’t require batteries but instead are powered by the wearer’s daily activities like walking, talking or holding an object.

The new device, which researchers from the National University of Singapore presented at the IEEE MEMS 2015 conference last week, can generate 90 volts of open circuit voltage when touched gently with a finger. Electrical and computer engineering professor Chengkuo Lee and his colleagues demonstrated that the new device can be used as a wearable self-powered sensor to track the user’s motion and activity.

Researchers have been trying for many years to make nanogenerators that scavenge body movements to power medical implants and other electronics. Georgia Tech investigators have used piezoelectric materials that generate electrical energy under mechanical stress. But in 2012 they reported a new kind of generator based on static electricity, the mechanism that makes your hair stand on end when you rub a balloon against it. They recently tapped the effect to make a slinky-like generator.

This friction-inducing phenomenon, called the triboelectric effect, electrical charge builds up on two dissimilar surfaces when they’re put in close contact. When they are pulled apart or flexed, a potential difference is generated and a current starts flowing between them that can be collected using an electrode.

“Skin, the most abundant surface on a human body, is a natural choice for one of the triboelectric layers,” says Lee’s graduate student Lokesh Dhakar. Device fabrication becomes simpler because you don’t need to make one of the layers, he says. “Also skin as a triboelectric material has a high tendency to donate electrons or get positively charged which is important in improving the performance of the device if the other triboelectric layer intentionally chosen as the one with a tendency to get negatively charged.”

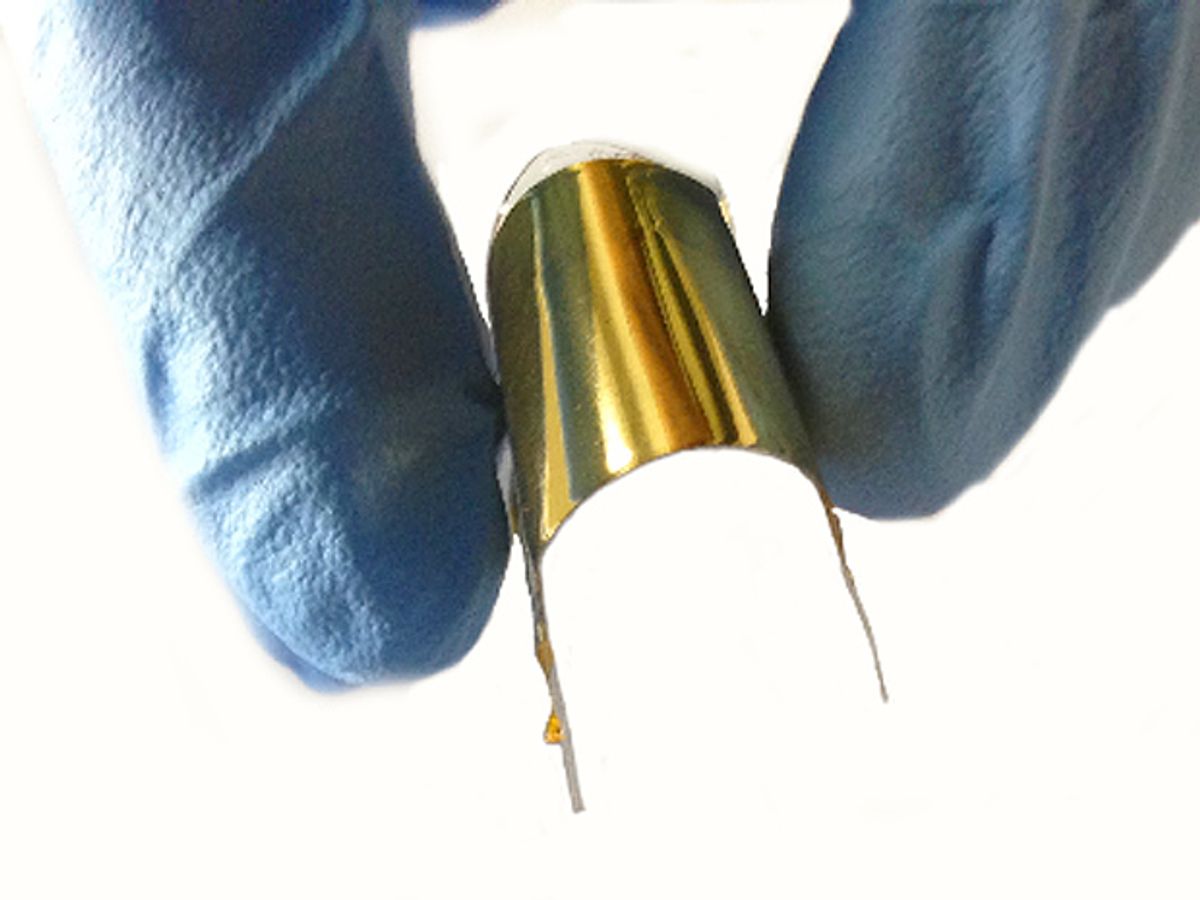

For that negative layer, Dhakar and his colleagues created thousands of tiny pillar-like structures on a flexible silicone rubber layer. Underneath the rubber sheet, they bond a 50nm-thick gold film that acts as the device’s electrode. The pillars increase the surface area of the device that touches the skin, which increases friction and hence the current produced. And the narrower the pillars, Dhakar adds, the higher the surface of the same effective area.

They tested the device by attaching it to a subject’s forearm or throat, nanopillar side down. Fist-clenching and speaking produced 7.3V and 7.5V respectively. The researchers tested the device as a human motion/activity sensor by attaching it on the forearm and measuring the pulse generated due to holding and releasing of an object.

Tapping the device generated the highest voltage of 90V and power of 0.8mW, Dhakar says. This could light up twelve commercial LEDs.

Wang’s group at Georgia Tech also reported a skin-based triboelectric generator in 2013. Theirs was much bigger, transparent and produced a large 1000V. But, says Dhakar, the limitation is that they used indium tin oxide as the electrode, which is not very flexible. Dhakar says his main goal was to make the device highly flexible so it could conform to human skin well in a patch of any size.

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.