Samsung’s Advanced Institute of Technology has been at the forefront of applying graphene to electronics, developing such things as zippy new types of transistors.

Despite these efforts, for graphene to succeed at reaching commercial applications in digital electronics a way of producing high-quality monolayer graphene in bulk needs to be developed.

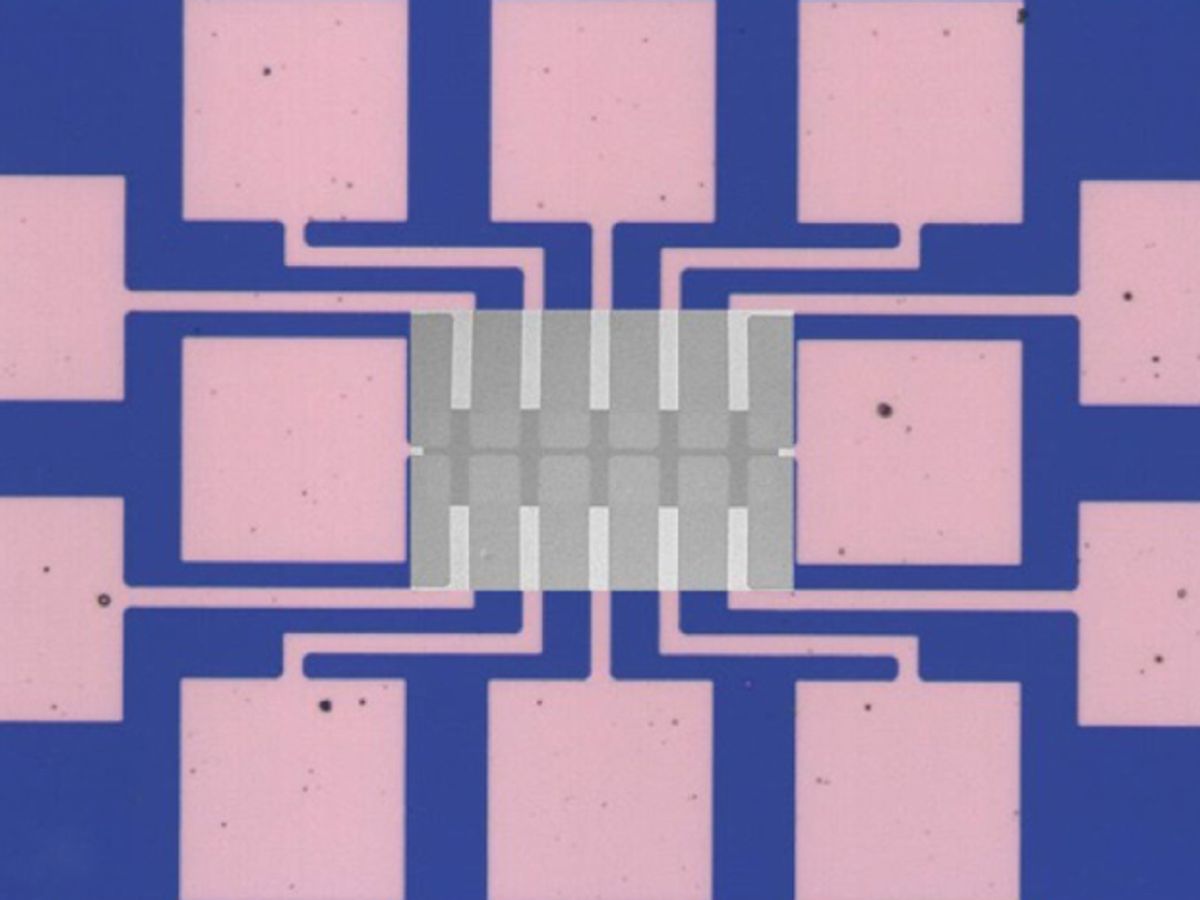

In this week's issue of the journal Science (“Wafer-Scale Growth of Single-Crystal Monolayer Graphene on Reusable Hydrogen-Terminated Germanium”), Samsung along with researchers at South Korea’s Sungkyunkwan University claim to have produced the first wafer-scale growth of wrinkle-free single-crystal monolayer graphene on a silicon wafer.

While there has been another successful demonstration of producing single-crystal monolayer graphene, that method is too costly and cannot be readily adapted to bulk-scale production.

The South Korean researchers overcame this production limitation in a process that used chemical vapor deposition (CVD) method for growing the graphene on the surface of a germanium coated silicon wafer coated. However, in this new method the researchers were able to transfer the graphene from the germanium without resorting to the damaging wet chemical etching process typically used. Instead, the researchers deposited a thin film layer of gold atop the graphene using a thermal evaporator. By then attaching the gold/graphene/germanium combination to a thermal release tape and applying a bit of pressure, the graphene and germanium substrate were easily separated .

Research late last year demonstrated that graphene loses none of its attractive electronic properties, such as high electron mobility, when paired with silicon. So it would appear that Samsung's new technique could help usher graphene into digital electronic applications, where high-quality material is essential.

But the hurdles are high in this field. To win a place in electronics, graphene has to be both cheaper and better than silicon and a host of alternative materials that have years of a developmental head start. For instance, in flexible electronics, which is one of the applications cited as a potential use for Samsung’s new graphene, the material not only has to prove itself better than the specially formulated plastics that currently rule the roost, but also needs to outperform carbon nanotubes, as well.

But you don' t have to wait for graphene to take over the semiconductor scene to see it used in electronics. Lower quality graphene should be just fine for thermal management systems and supercapacitors for portable electronics that would not just power the devices but serve as a high-frequency filter.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.