Of the extensive equipment required for power flow control and safety across the grid, transformers are needed for adjusting voltage levels in power transmission lines. However, unwanted noise is produced by vibrations in the transformer and by the fans and pumps used in the cooling system. This sound is often noticeable as a faint humming or buzzing, audible to passersby who get close enough.

Reducing this noise is necessary and desirable due to both safety regulations and comfort. ABB, a major transformer manufacturer with offices throughout the world, makes use of numerical simulation in COMSOL Multiphysics® software to analyze the multiple sources of sound from transformers. In their endeavors to understand and optimize ABB's transformer designs for minimal hum, Romain Haettel, Anders Daneryd, and Mustafa Kavasoglu of ABB Corporate Research Center (CRC) modeled the mechanical, acoustic, and electromagnetic behavior of the transformer components coupled together in one simulation.

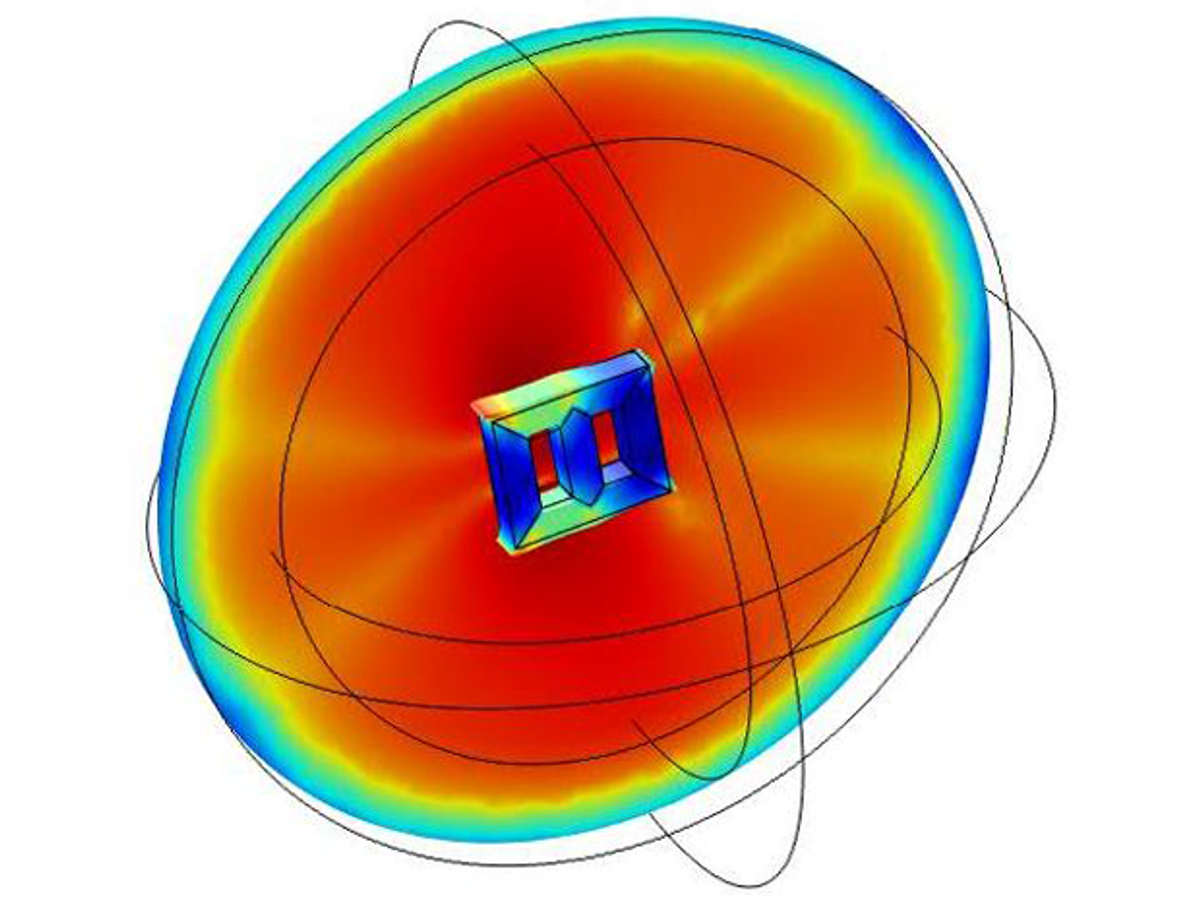

The transformer design in question comprises a magnetostrictive metal core with coils around different sections, a tank enclosure, and insulating oil in between. The CRC team modeled the magnetic flux generated in the core and coil windings; the mechanical strains and displacements in the core due to magnetostriction, which cause vibrations; and the Lorentz forces due to alternating currents in the coils. This allowed them to understand how all these factors influence the acoustic pressure in the tank, and ultimately the levels of sound emitted.

They also analyzed the relationships between different design parameters, such as tank thickness and material properties, and the resulting hum. Putting all of their newfound understanding together, they adapted the geometry and configuration of the transformer components to minimize noise and provide the best possible designs.

Using the Application Builder tool available in COMSOL Multiphysics® the team built a simulation app to extend the knowledge gained from their simulations to the rest of the designers at ABB as well as to the business unit. The customized apps created from their simulation simplify the testing and verification process for other departments by letting app users check how different designs would affect the final transformer hum without needing to be familiar with the original mathematical models. Haettel, Kavasoglu, and Daneryd made their simulation available to their colleagues, spreading their analytical capabilities throughout the company and expanding the reach of simulation for design improvements.

Learn More: https://comsol.com/c/3wzb