Circuits that use tube electronics like thyratrons can be alien to engineers raised in the solid-state era. For example, these circuits require high voltages to operate, and power must be supplied to heat filaments. This complicates design, construction, and debugging. But if you want to understand how electrical engineers got it done before semiconductors became ubiquitous, then taking the plunge into the world of tubes can be very educational. This supplement to my February Hands On article contains additional information about how I re-created the SIGSALY analog-to-digital converter—and actually got it working.

Design

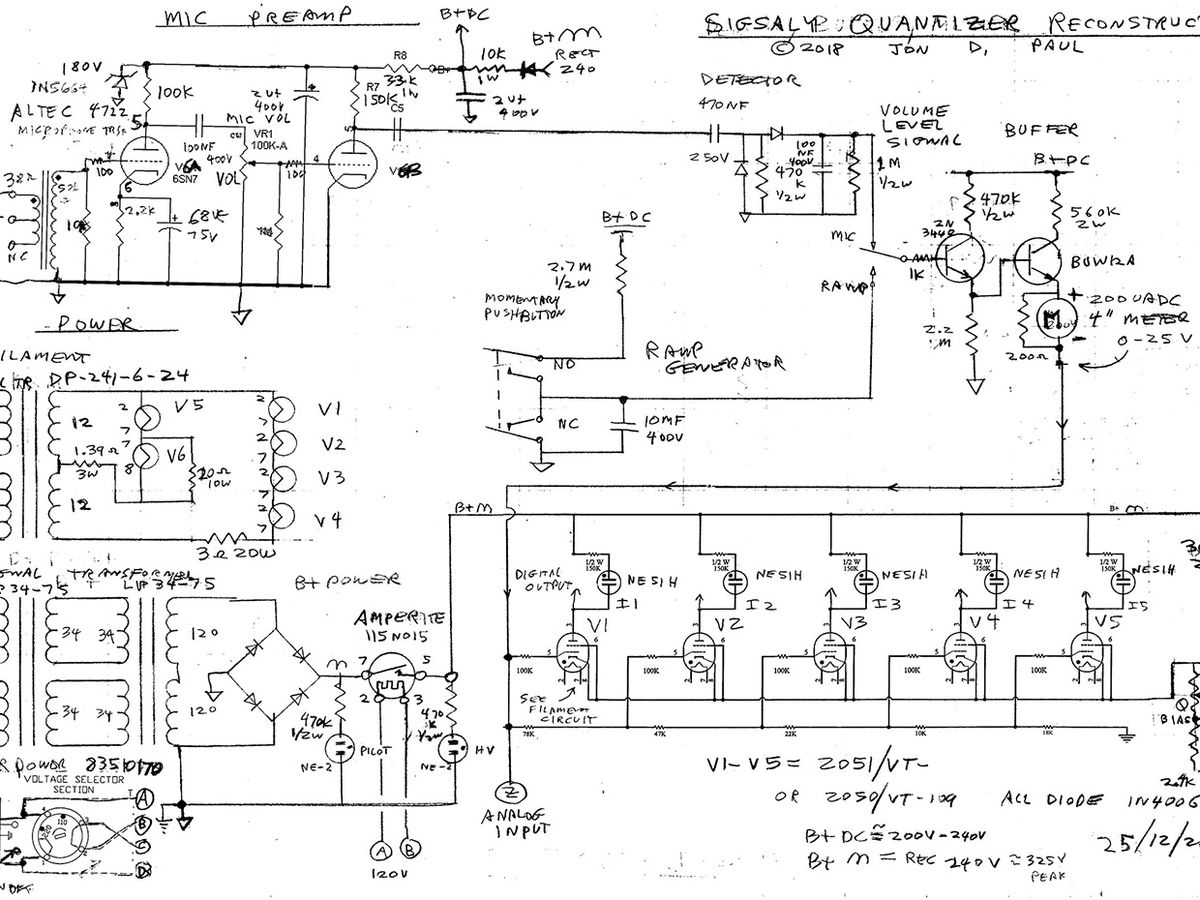

The converter is built around five VT-109/2051 thyratrons. The VT-109/2051 is an industrial control argon tetrode, functionally equivalent to a silicon controlled rectifier. When the thyratron’s trigger voltage is applied to the anode, it “fires” and latches up until the anode voltage is removed.

In the SIGSALY quantizer, a pulsed anode voltage is applied, and so the five thyratrons serve as strobed comparators. The analog input voltage is fed into a five-tap logarithmic resistor divider, whose taps drive the thyratron grids. As the input voltage increases, the five thyratrons trigger in sequence (not binary, but a “thermometer code”). In the SIGSALY quantizers, the thyratron anode currents were summed to form a six-level quantized output voltage (zero, plus each of the five levels detected by the comparator). In the original SIGSALY design, the high-tension (B+) anode supply was a 350-volt, 20-millisecond-long pulse, used to sample the input and then to reset the thyratrons.

My reconstruction uses the same five-tap logarithmic ladder and thyratrons as in the original SIGSALY quantizer, with a full-scale input of 25-V and 1.0-V tap voltages. It differs a little in that instead of a 350-V, 20-ms B+ pulse, the input is sampled by supplying full-wave rectified 240-V AC power to the anode circuit, which resets the thyratrons at the power line zero-voltage crossings, every 8.33 or 10 ms.

Setting the thyratron’s cathode bias voltage correctly was critical, but the VT-109’s specifications indicated a wide range. So I did some experimenting, using a string of diodes in series with the cathodes to set the bias voltage, which showed that a bias of 2.5 to 3.0 V was optimum. However, I also discovered that the diode string bias voltage varied with the total thyratron current and was only coarsely adjustable in 0.6 V increments. I replaced the diodes with a Texas Instruments TL-431 C shunt regulator [PDF] to supply a finely adjustable, highly regulated cathode bias voltage.

The complete re-creation includes the power supply circuitry, a microphone preamplifier, a 10-second ramp generator as an alternate input signal source, and a meter display for comparing the input to the converter’s output, as indicated by a set of five neon lamps. I scrounged a 120/240-V to 24-V transformer, so the 6.3-V supply that heats the tube filaments were wired in series. To prevent cold cathode “sputtering” damage, the thyratron filaments must be preheated before applying the B+ anode voltage. I use an Amperite thermal time-delay relay (115NO15),which switches the B+ on after a warm-up delay of 15 seconds.

The dynamic microphone is coupled with a vintage Altec-Lansing 4722 transformer to a 6SL7GT dual triode, which amplifies the signal by 60 decibels in two stages. The preamp output is AC coupled, diode detected, and buffered. This signal is then fed to the large panel meter for analog indication, and also drives the quantizer input. Alternately, a push button starts a signal ramp generator by charging a 10-microfarad plastic capacitor from B+ via a 2.7-megaohm resistor.

Debugging

As described in the main article, I started debugging just before departing from California to Paris. I discovered that the filament voltages were off tolerance by 25 percent. The root of this problem was that the preamp 6SL7GT tubes and the 2051 thyratrons had differing filament currents and thermal time constants. That was fixed by adding power resistors in series and parallel to equalize the voltages and to reduce the warm-up transients.

I fixed a few other wiring errors, and the quantizer began to work a bit, but only two of the five thyratrons triggered, the microphone preamp had full-scale oscillations once a second (“motorboating”), and the B+ anode power became heavily overloaded by the thyratron currents as each tube fired.

After doing some more debugging in France, I determined the motorboating was due to a combination of excessive thyratron currents, poor B+ supply load regulation, and lack of preamp B+ noise rejection, which caused a set of interactions. The upshot was that as each thyratron triggered, the B+ supply was loaded by an additional 5 milliamps (for a total of 25 mA), causing fast negative 30-V B+ transients, which were fed back to the preamp anodes.

I reduced the thyratron currents by removing load resistors, so the anode load was just the neon lamps. This reduced the current per thyratron from 5 mA to 560 microamps. I added a two-stage RC filter and a 180-V Zener diode to stabilize the preamplifier B+ supply.

The motorboating stopped, but when the preamp gain was near maximum, two or three thyratrons would get stuck in the “on” state, without input. The symptoms changed with the type of microphone and whether the input was open or shorted. I probed the preamp with an oscilloscope and voilà: I discovered a 22-kilohertz parasitic oscillation present in both preamp stages, as well as at the transformer primary and secondary.

After some analysis, I realized that the parasitic oscillation was due to the high Q factor of the microphone transformer. The transformer’s shunt capacitance and its inductance formed an LC tank circuit, which along with stray anode-to-grid capacitance in the 6SL7 tube, caused a positive feedback loop. The solution was to damp the transformer secondary termination with a 10 kΩ resistor instead of the recommended 50 kΩ matching impedance.

Now I found that the last thyratron, intended to trigger when the input voltage reached 25 V, refused to fire. I found two causes: loading of the ramp RC circuit by the emitter follower transistor base current, and the microphone preamp clipping the positive peak of the half-wave. The excess ramp RC loading was fixed by adding a 2N3440 transistor in front of the existing BUW12 transistor, to form a high voltage Darlington pair emitter follower. That reduced the buffer input current from 30 µA to 1-2 µA.

The ramp input could now fire all five thyratrons, but the input from the microphone still could not. I changed the preamp bias, but the positive peak clipping limited the DC detector output to less than the 25 V needed to fire the fifth tube. Finally, I realized that the half-wave peak detector could easily be changed to a half-wave voltage doubler!

I also noticed that touching the volume control injected noise and hum. The volume control has a metal case, but it was electrically floating because of the plastic chassis, so I added a separate ground to the volume control case.

Finally, I calibrated the converter by plotting the outputs against an ideal logarithmic conversion curve. The last two thyratrons were off the desired curve. I discovered that the thyratron trigger voltages varied 2:1 from tube to tube. That was fixed by selecting the VT-109/2051 tubes so that their trigger voltages were consistent, and then readjusting the thyratron grid bias and trimming the resistor ladder several times.

A correction to this article was made on 28 May 2019.

Read full article: Rebuilding a Piece of the First Digital Voice Scrambler

Read full article: Rebuilding a Piece of the First Digital Voice Scrambler