27 March 2008—Earlier this month, IEEE Spectrum reported on the development of bendable, twistable electronic circuits whose performance nearly matches that of conventional CMOS chips. The new circuits, developed by a team of researchers at the University of Illinois at Urbana-Champaign led by Professor John A. Rogers, are built from ribbons of silicon only a few nanometers thick that are mounted on flexible plastic substrates.

Today, in a report published online by the journal Science, the same group says it has developed an improved plastic circuit that is not only flexible but also stretchable and foldable. To make it foldable, the researchers looked at the behavior of everyday objects and observed that it’s much easier to fold a magazine than a telephone book, says Rogers. So they decided to make the circuit much thinner.

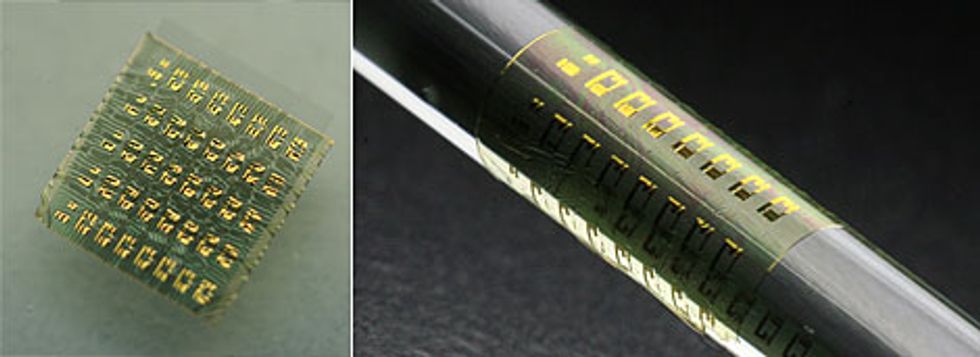

The original recipe for flexible CMOS circuits comprised a 2- to 3-micrometer circuit layer sitting atop a plastic substrate as much as 100 µm thick. It could curve around a small roll of coins. But the new version has a total thickness of only 1.7 µm, including the plastic, which gives it the ability to wrap around a rod whose diameter is roughly 85 µm.

Rogers’s group makes plastic circuits by transferring thin ribbons of silicon onto glue-coated plastic using a patterned rubber stamp. But before the ultrathin silicon layer is applied to the substrate, the plastic is heated, causing it to expand. Once the circuit layer is deposited and chemically bonded to the expanded substrate, the plastic is allowed to cool and contract. Relaxing the strain causes the circuit layer to buckle and form wavy patterns like the bellows of an accordion. It’s the folds and wrinkles that give the circuit the ability to stretch and bend without breaking. Rogers says that in laboratory tests, the circuits, after a few hundred stretch-and-release cycles, showed no signs of fatigue.

SHRINK, WRAP

: This circuit sheet [LEFT] has not aged rapidly. The wrinkles make it possible to stretch the sheet over a sphere or an irregularly shaped object without breaking the sheet or damaging its current-conducting structures. To wrap circuits around a rod as thin as a strand of hair [RIGHT], the researchers made them superthin.

The Illinois researchers are proceeding with partnerships with physicians who are developing biomedical devices incorporating the circuits. For example, a clinical neurosurgeon at the University of Pennsylvania, in Philadelphia, is working with the Illinois team to create an implantable sensor that will monitor electrical activity in the brain to help predict the onset of epileptic seizures. The device may also work in reverse, sending electric pulses that head off the seizures. ”This requires a device that will conform to the rippled geometry of the brain, because the deep creases in the lobes are where a lot of the action happens,” says Rogers.

To Probe Further

Here’s a movie showing the plastic CMOS circuit wrinkling up after being printed on plastic.

Willie Jones is an associate editor at IEEE Spectrum. In addition to editing and planning daily coverage, he manages several of Spectrum's newsletters and contributes regularly to the monthly Big Picture section that appears in the print edition.