Solar panels are obeying the will of Moore's Law by getting ever cheaper and more efficient. What's not getting cheaper or more efficient is the human labor required to install them. This keeps the cost of going solar higher than us duck-squeezing envirinmintl types would like, but robots are busy coming to our rescue by setting up solar power plants much cheaper and much, much faster.

Here's the executive summary, since I've never done an executive summary before and it sounds fancy: using robots to set up a 14 megawatt solar power plant can potentially cuts costs from $2,000,000 to $900,000, while being constructed in eight times faster with only three human workers instead of 35.

So there you go! If you're still reading, we can tell you a little bit about the robot that performs this incredible feat of engineering efficiency: it costs just under a million bucks, but it's built from off-the-shelf parts and in continuous use will supposedly pay for itself in either no time at all or less than a year, whichever comes last. And like all robots, using one of these things means you can get work done in rain or sleet or snow or darkness with no complaints, but if you find yourself installing solar panels where all of those things are occurring at once, you should probably just give up and go someplace, you know, sunny.

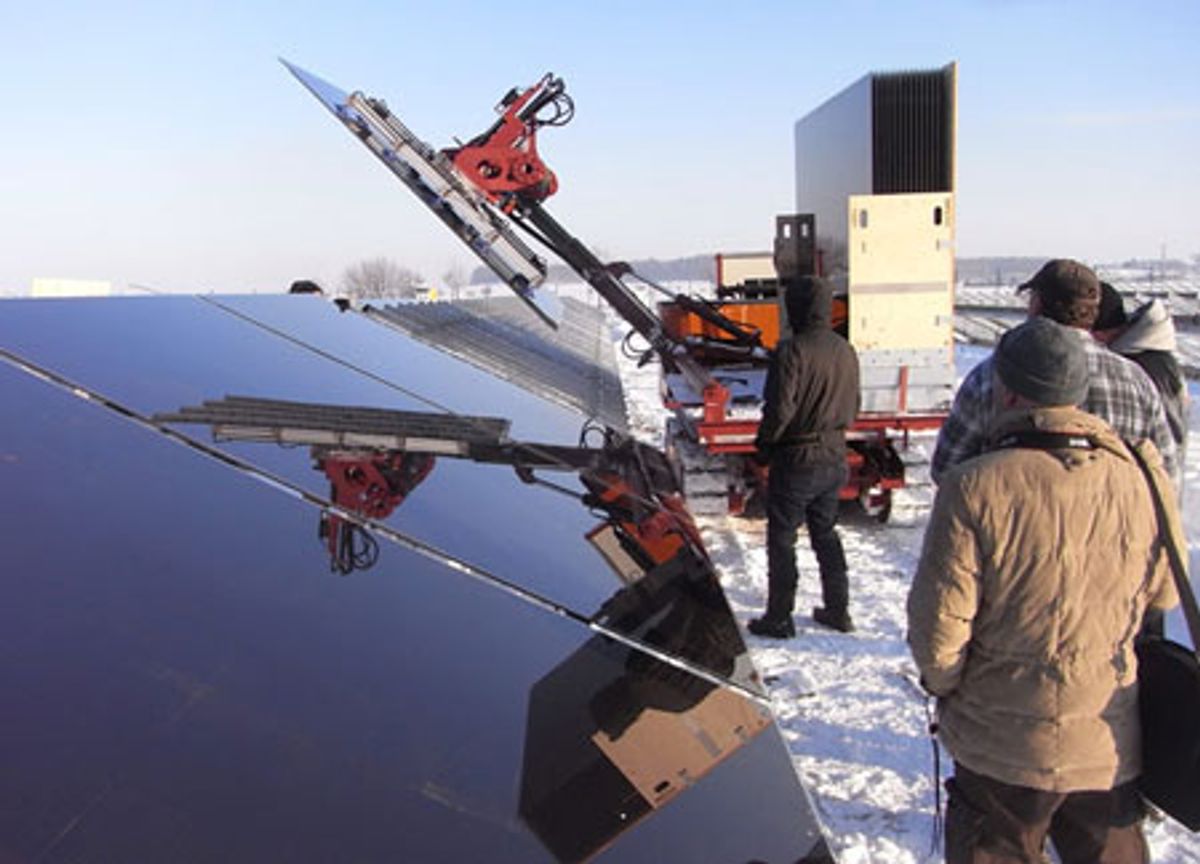

The robot itself has a mobile base that runs on tank treads, and a robot arm grips huge 145 watt panels one at a time and autonomously positions them in just the right spot on a pre-installed metal frame. Humans follow along behind, adding fasteners and making electrical connections, but secret plans are underway to roboticize these jobs too. Zee Germans, being big fans of solar power in their quest to go 80% renewable by 2050, are quite interested in putting robots like these to work, as are the Japanese, who want to construct solar farms near Fukushima within the next six months.

Via [ Tech Review ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.