One of the downsides of optical discs is that they are not particularly durable, leading researchers to look at using quartz glass as a replacement for the typical plastic used. The fact that these discs are fragile has also demanded the rather expensive practice of keeping multiple duplicates at large data centers in order to safeguard against loss of data through breakage.

Now researchers at Swinburne University of Technology in Australia have developed a polymer using graphene oxide that makes it possible to retrieve all the information from the disc even in the case of it breaking.

It should be noted that graphene oxide is different from graphene in a couple of ways. First, the manner in which it is produced is fundamentally different. It is made via a chemical reduction process rather than the mechanical or thermal exfoliation processes used to create single layer graphene. Secondly, it differs significantly in its properties. It lacks graphene's unmatched electron mobility, so it's not the great conductor that graphene is. It does, however, have a property that makes it ideal for optical storage applications: a fundamental fluorescence that is useful for multimode optical recording.

The Swinburne researchers took advantage of that fluorescence, demonstrating that when a laser is focused onto a graphene oxide polymer, the beam increases the material's refractive index by 10 to 100 times. All materials have a refractive index, which is essentially a measurement of the speed of light and how much it bends when it passes through a medium.

“The unique feature of the giant refractive-index modulation together with the fluorescent property of the graphene oxide polymer offers a new mechanism for multimode optical recording," said Professor Min Gu, one of the researchers, in a press release.

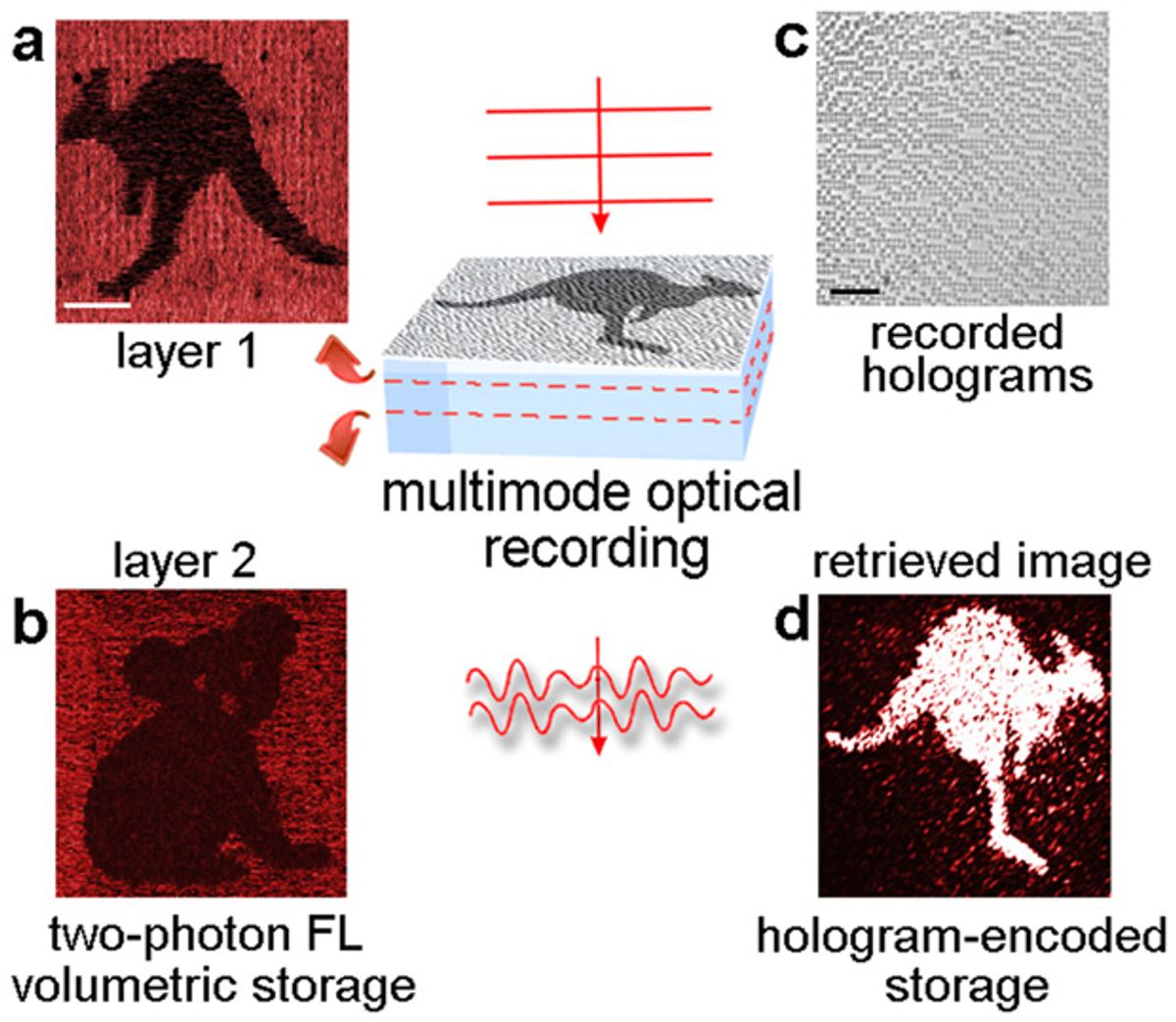

In their demonstration, which was published in the journal Scientific Reports (“Giant refractive-index modulation by two-photon reduction of fluorescent graphene oxides for multimode optical recording”), the researchers encoded the image of a kangaroo in a computer-generated hologram. The researchers then rendered the hologram as a three-dimensional recording on the graphene oxide polymer.

One other attribute of the recorded hologram is that it lends itself to secure coding. You can’t actually see the encrypted images of the hologram with a microscope, but they can be seen when the images are diffracted.

"The giant refractive index of this material shows promise for merging data storage with holography for security coding," Professor Gu said in the release. "This exciting feature not only boosts the level of storage security, but also helps to reduce the operation costs of big data centers that rely on multiple physical duplicates to avoid data loss."

The researchers believe that optical data storage is only one application that could be impacted by the technology. They believe it could revolutionize flat screen displays and solar cell technology.

Gu adds: "The giant refractive index we discovered shows the promise of graphene to merge electronics and photonics for the platform of the next generation information technologies."

Image: Swinburne University of Technology

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.