Researchers at Harvard's Wyss Institute for Biologically Inspired Engineering announced yesterday that they've created a "gut-on-a-chip." The silicon polymer chip has microfluidic channels containing the cells that line the human intestine. The researchers say that this device offers a new way to study intestinal diseases and the drugs that treat them, while improving on both Petri dish- and animal-based tests.

It's a neat example of intellectual crossover: The microfabrication techniques used in this research are derived from semiconductor manufacturing.

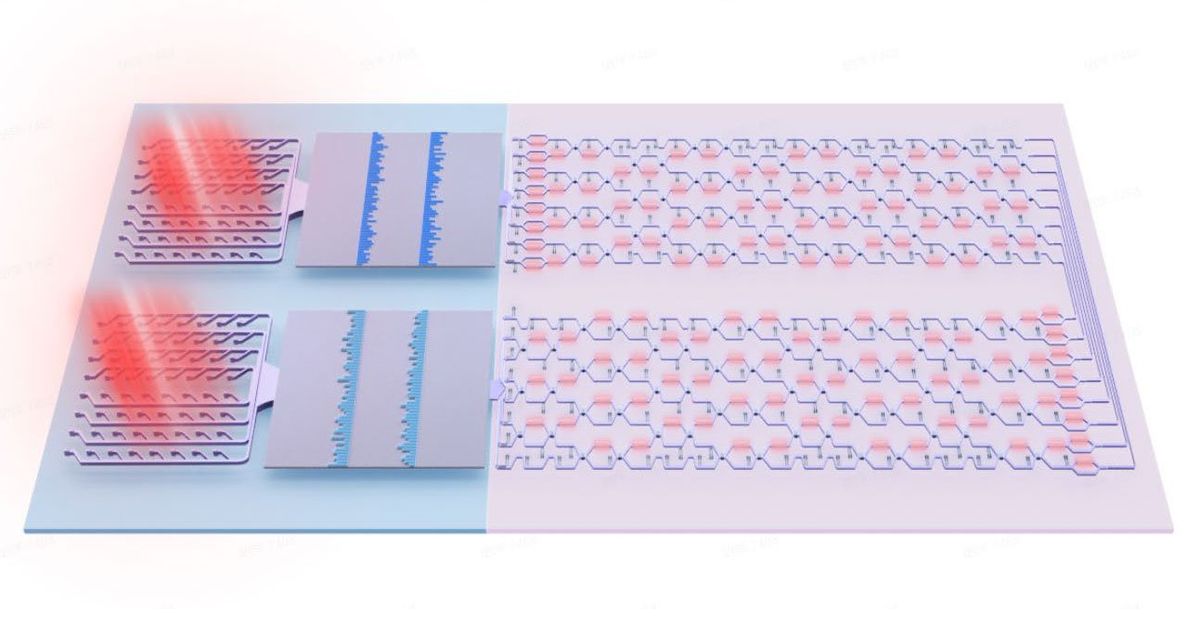

Inside the gut-chip, there are two microfluidic channels (shown in the photo with blue and red fluids) that are separated by a porous, flexible membrane; this mimics the intestinal barrier that nutrients pass through. The membrane is coated with epithelial cells, the type of cells that line the human intestine. Researchers replicated the peristaltic motions that move food through the intestines by applying suction to the two sides of the central channel. The researchers even grew colonies of common intestinal microbes in the channel to complete the model.

Such a device could help medical researchers study digestive disorders like Crohn's disease and ulcerative colitis, and could also allow researchers to study how orally administered drugs are absorbed by the body. The work was published in the journal Lab on a Chip earlier this month.

Organs on a Chip from Wyss Institute on Vimeo.

As Wyss researchers explain in this video, organ-on-a-chip research has the potential to aid pharmaceutical companies in their quest for new and better drugs—while at the same time reducing the need for animal testing. Geraldine Hamilton, a senior staff scientist, says in the video that pharmaceutical companies are experiencing high failure rates in their drug development process in part because the animal models they use aren't always predictive of how the drug will work in the human body. There are plenty of other reasons why animal testing isn't ideal: It's expensive, lengthy, and sometimes controversial.

Wyss researchers previously built a lung-on-a-chip, and they're currently working on both a spleen-on-a-chip (with funding from DARPA) and a heart-lung micromachine (with funding from the National Institutes of Health and the U.S. Food and Drug Administration).

But back to guts. For an entirely different and much more visceral approach to modeling the human digestive system, check out this IEEE Spectrum video about "the world's most sophisticated artificial gut." Watch as the large mechanical system deals with a can of chicken and vegetable soup.

Image and video: Wyss Institute

Eliza Strickland is a senior editor at IEEE Spectrum, where she covers AI, biomedical engineering, and other topics. She holds a master’s degree in journalism from Columbia University.