Ray Guns Get Real

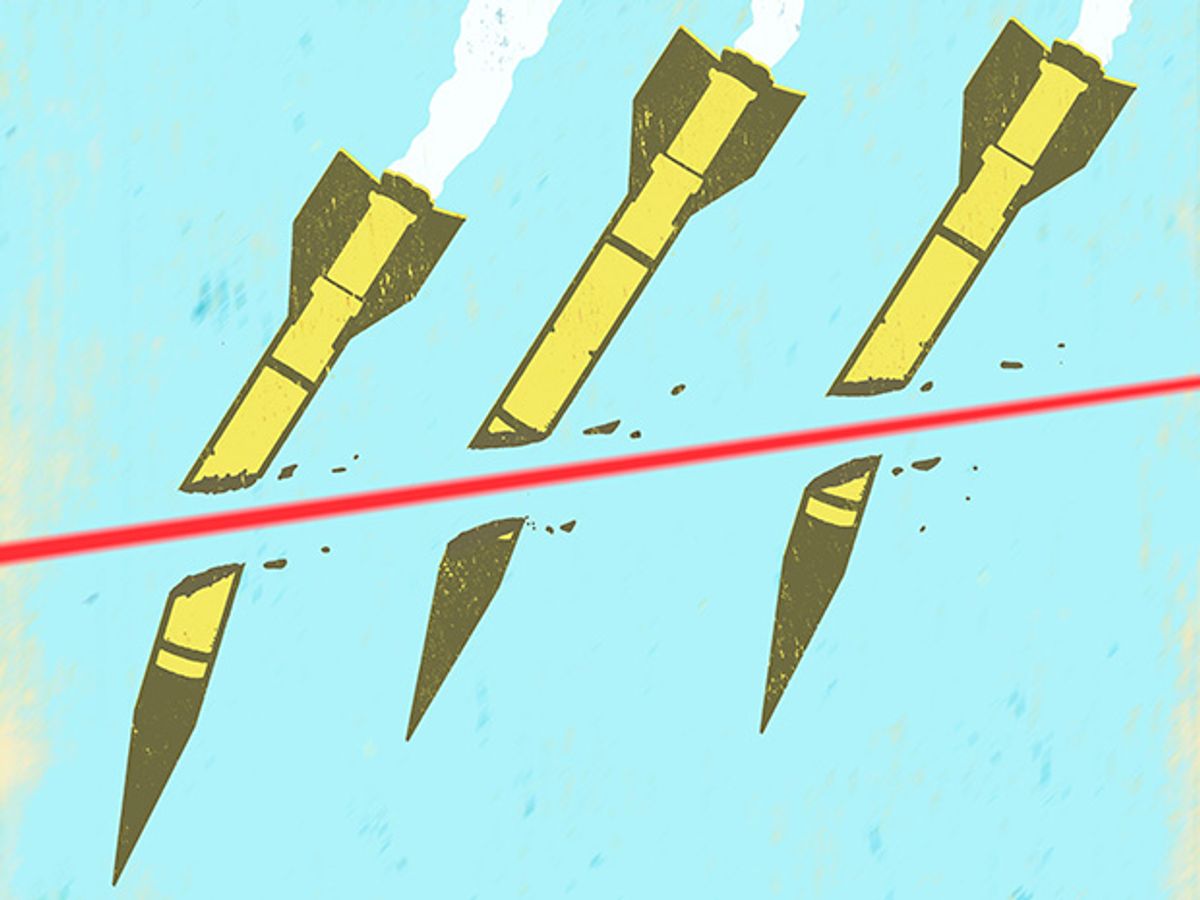

Cheap rockets fired by insurgents are taking a deadly toll in the Middle East. Can a new generation of solid-state lasers blow them out of the sky?

Rockets, mortars, and other forms of artillery have a long and grim history on the battlefield. In a conventional war, an army being bombarded by these from afar can respond by firing back at the attacker’s battery. But you can’t turn the massive firepower of modern armies onto insurgents hiding among civilian populations without courting disaster. Instead of striking the enemy, who run to other hiding spots after firing their weapons, such retaliation would mostly hit civilians.

What the U.S. military dearly wants is a weapon that can defend against such attacks more selectively, shooting down explosive-laden projectiles in the air before they reach their targets. The armament should be easy to field and should strike at the speed of light, but it should not send streams of bullets screaming toward the horizon. In short, the military wants a laser weapon that’s small and rugged but powerful enough to ignite explosive payloads on incoming projectiles while they’re still a safe distance away.

It’s a bold vision for laser defense, bolstered by a dramatic technology demonstration that didn’t make Page One: For five solid minutes in March, an electrically powered solid-state laser pumped out 100 kilowatts of infrared light, the first of its kind to make “weapons class.”

Each armed service has its own plans for that technology. The U.S. Army and its Israeli allies want truck-mounted lasers to zap short-range rockets on the battlefield or border. The U.S. Air Force wants compact lasers for fighter jets. The Navy wants to defend ships against attacks. And research efforts in China and Russia have been reported as far back as 1995.

And yet, laser weapon R&D is celebrating its 50th birthday this year without much to show for it. In fact, in early April the U.S. Defense Department shelved plans to buy a fleet of 747s to house giant gas-filled antimissile lasers. The old technology was proving too bulky and underpowered to blow North Korean missiles out of the sky without flying within antiaircraft range.

High-energy laser research is at an inflection point. Powered by semiconductors, a new generation of lasers promises new opportunities—and presents a whole new batch of problems.

Laser weapons, like flying cars, have been demonstrated many times, but in the real world their problems have always outweighed their benefits—literally. Weight cripples laser weapons and flying cars alike. Most experimental laser weapons have been so big and heavy that cynical observers have joked that their only conceivable combat use would be to drop them on the enemy.

That’s because the size of a laser weapon is inversely related to its efficiency—and laser efficiencies can be pretty dismal. The red helium-neon gas laser long used for classroom demonstrations turned only 0.01 to 0.1 percent of electrical power input into light. The diode lasers used in today’s inexpensive laser pointer do much better, converting about 10 percent of the electrical energy they draw from their batteries into light. The rest is lost as heat. This is no big deal for a milliwatt-power laser pointer, because the heat generated is negligible. But it’s a thorny problem for a laser weapon. At 10 percent efficiency, it would take 1 megawatt to generate a 100-kilowatt laser beam, leaving 900 kW as heat that must be dissipated somehow.

But that didn’t stop the U.S. Missile Defense Agency from building a megawatt laser. To achieve a 1-MW beam with 10 percent efficiency would require a whopping 10 MW of input energy and produce a hefty 9 MW of waste heat. Nevertheless, later this year a beast with such power, called the Airborne Laser (ABL), will be put to the test of blasting dummy nuclear missiles from the sky.

Here’s how. ABL is the latest example in a class of high-energy lasers called flowing-gas lasers. They are powered by burning chemical fuels like those that drive rocket engines. Hot molecules in the gas emit a cascade of light emissions, producing a powerful laser beam. Rocket-engine lasers have generated infrared beams that can reach a couple of megawatts for a few seconds at a time. The technology used in ABL can turn more than 20 percent of the combustion energy into laser light in the laboratory, but ABL’s efficiency is undisclosed. In such a laser, the exhaust gas carries away the energy left behind as heat.

But so far the US $5 billion ABL can barely squeeze into a Boeing 747. The laser is completely unsuited to the battlefield. It’s being designed to destroy long-range missiles rising through the atmosphere a couple of hundred kilometers away, but it’s vastly overpowered for the comparatively easy job of hitting slow-moving mortar shells only a kilometer or two away. It would be like shooting deer with a cannon. So in 1996 the U.S. Army and the Israeli Ministry of Defense teamed up to test smaller lasers against mortars and rockets. For that task, they tapped Redondo Beach, Calif.–based aerospace contractor TRW (acquired by Northrop Grumman Corp. in 2002) to build a 100-kilowatt-class flowing-gas laser, a compact version of ABL.

The result, called the Tactical High-Energy Laser (THEL), made laser defense look promising. In 2000, it shot down a short-range Katyusha rocket over the White Sands Missile Range in New Mexico. But by 2004 the United States and Israel agreed THEL wasn’t up to the job, ending any further tests.

One problem with THEL was its large footprint. It required several trailer-size containers; outdoor tanks filled with exotic chemical fuels and the “exhausted” chemicals that had fed the reaction (which would need to be protected from enemy fire or sabotage); and a platform-mounted apparatus called a beam director, similar in size and shape to a big sky-scanning searchlight. But the real killer for field commanders was the logistical nightmare they envisioned. Aside from its bulk, characteristic of flowing-gas lasers, THEL would be useless without its special fuels, and it also produced toxic, corrosive hydrogen fluoride gas, which would require special handling. “A chemical laser on a battlefield is more of a hazard than the threat it is trying to mitigate,” says John Boness, chief technologist at Textron Systems, a laser-weapons contractor in Wilmington, Mass.

The U.S. Army and Israel had their sights set on something more nimble that could fit on an armored vehicle the size of a motor home and that would be ready to roll when it arrived on the battlefield. John Wachs, chief of the directed-energy division at the Army Space and Missile Defense Command, in Huntsville, Ala., explains the ultimate result of that conclusion: “The Army decided they would prefer solid-state, all-electric devices.”

Solid-state lasers are far simpler than their flowing-gas cousins. Small versions have been in the U.S. arsenal since the Vietnam War, but they are just glorified laser pointers: The low-power beams mark targets with invisible infrared spots, which allow smart bombs to home in. Such lasers could probably kill a fly, but nothing bigger.

The first laser ever built was also solid state. It used bright pulses from a flashlamp (which creates an intense white light) to illuminate a stubby ruby rod. The flashes excited chromium atoms in the ruby, which prompted the atoms to release their energy as red photons in a laser beam.

Modern solid-state lasers are powered in the same general way—light from an external source transfers energy to the atoms in a crystal, and these emit laser light. But instead of ruby rods, engineers have developed lasers that use more sophisticated crystals doped with a rare-earth element called neodymium. These simple, durable lasers are used widely in industry and the military.

Despite the advances with materials, at most just a few percent of the electrical energy from a flashlamp makes it into a laser beam. Solid-state laser materials don’t dissipate heat well, so trying to crank up the laser output too much will warm the crystal rod. Exceeding the strict heat limits of this material even by a negligible amount causes internal stress and degrades the beam quality, which means it won’t focus tightly on the target. Add even more heat and the rod can crack or shatter. For decades, this combination of low efficiency and poor heat dissipation made attempts to develop high-energy solid-state lasers seem like a waste of time.

But by the 1980s, the industry began replacing the old flashlamps with semiconductor diode lasers. Both tools for powering solid-state lasers use two-stage processes, with electrical input first converted into light and the light powering the laser. But the diode laser is far more efficient. Like light-emitting diodes, diode lasers generate light when mobile electrons become attached to atoms at the border of two different semiconductor materials. Thanks to strategically placed mirrors, diode lasers convert much more input electricity into light—light that’s limited to a narrow range of desirable wavelengths. Contrast that with flashlamps, which give off energy across the entire visible spectrum, the main reason why so much of their light is never absorbed and converted into laser energy.

A diode laser can transform roughly half the input electricity into light, and a solid-state laser can, in turn, convert about half of the energy in that diode laser’s output into a high-quality laser beam. So less than a quarter of the input energy emerges in the beam. That’s 25 times as much as what you get with a flashlamp. And the improved efficiency lessens the heat-dissipation problem, which should make it easier to construct a battlefield laser.

Thel had established that destroying a moving target at a distance of a kilometer or two requires around 100 kW of laser power. That oomph is needed mostly because of the spreading of the laser beam.

Although people often think of laser beams as being pencil thin, beyond a certain distance from the source the beam spreads out conically, like a searchlight. If the beam starts with a diameter of one centimeter, it might well expand to something like 10 centimeters at 200 meters’ distance. By the time it hits a target 2 km away, the beam could be a meter across. Extending the target distance from 200 meters for stationary objectives to 2 km for rockets and mortars reduces the laser power per unit area—the critical factor in igniting the explosives in a bomb or rocket—by a factor of 100. And to counter that reduction, you need to boost the power, in turn, by a factor of 100.

Although THEL had gone nowhere, the Army had been hedging its bets all along. In 1997, not long after work started on THEL, the Army tapped Sparta, a defense contractor headquartered in Lake Forest, Calif., to build a Humvee with a turret-mounted solid-state laser to destroy unexploded ordnance exposed on the ground. They named the test system Zeus, after the thunderbolt-wielding king of the Greek gods.

A soldier operating Zeus would use the turret to train a green laser pointer on the target. With the unarmored Humvee parked between 25 and 250 meters away—far enough to keep out of danger—the soldier would then switch on the high-energy laser beam, invisible to the human eye because of its 1-micrometer infrared wavelength. The laser Sparta installed at its Huntsville location, before shipping Zeus to Afghanistan in 2003 for field tests, emitted only a kilowatt—small potatoes by laser-weapon standards. Although the beam Zeus uses can burn exposed skin, it is nowhere near as deadly as an ordinary bullet. But the targets were easy ones, stationary and clearly in the line of sight. Other than the sparkles of dust particles ignited by the heat, the only trace of the beam was the zone it heated on the target, as if it were sunlight focused onto paper. If you were viewing the target with an infrared camera, you’d see a small spot begin to glow as Zeus heated the casing. The steadily brightening spot would grow in size as the laser’s heat penetrated deeper, through the case and finally into the explosive payload. The show would end with, well, a bang.

Zeus went on to field trials. At Bagram Air Base in Afghanistan, Zeus destroyed more than 200 rounds of ordnance in six months of field trials, including 51 rounds in one particularly successful 100¿¿¿minute span. The Army was impressed: Zeus wasn’t powerful enough to destroy buried mines or munitions, but it was small enough to be mobile, and it could take on improvised explosive devices—Iraq’s famously deadly IEDs—if they were not buried under sand.

Illustrations: Steve Stankiewicz; Photo: Lawrence Livermore National Lab

To tackle the problem of scaling up the power of a solid-state laser to compensate for distance, in December 2002 the U.S. military launched a grand challenge called the Joint High Power Solid State Laser (JHPSSL). The Army’s goal was a 100-kW electrically powered laser that it could use for distant battlefield targets. The Air Force wanted a similar laser for its F-35 Joint Strike Fighter, and the Navy hoped such a laser could fend off small-boat attacks like the 2000 suicide bombing that killed 17 sailors and seriously damaged the USS Cole. Field commanders insisted that the laser not require any special power systems, so it had to run on electricity from the diesel generators that run other front-line equipment.

The first step was a competition to reach 25 kW by late 2005 between four entrants: Northrop Grumman, Textron, Raytheon, and Lawrence Livermore National Laboratory. The 25-kW output beam needed to remain tightly focused for 300 seconds while ensuring that the laser didn’t self-destruct. The basic approach was clear—use diode lasers (here acting as what laser physicists call pump diodes) to inject light into thin slabs of laser material containing neodymium atoms, which in turn emit light at 1.06 µm in the near infrared. The pump beam passes through the slab and excites the atoms to produce high-output energy, and the heat can dissipate through the wide top and bottom.

Cooling is a critical issue, because solid-state lasers convert only about 20 percent of their electrical input energy into light output. Again, that may be good by laser standards, but it still means that 80 percent of the input energy winds up as heat—four watts of heat for every watt in the output beam. Much of that heat goes into the laser slab. The results of sending a laser beam through a hot slab are similar to what happens when you park your car in an open lot on a summer day. Just as the rising air currents bend the light over the hood, making it ripple and waver, uneven heating in a slab will break up or spread a laser beam. The farther the beam has to travel in these conditions, the more it will spread and the less damage it can do. And while rocket-engine lasers can blow away their waste heat as exhaust, solid-state lasers need another way to keep from frying.

Lawrence Livermore had already developed a clever but elaborate way to deal with the problem, resulting in what’s known as a solid-state heat-capacity laser. Several ceramic laser slabs, 10 cm square and 2 cm thick, are mounted on four rotating wheels. For 10-second intervals, arrays of pump diodes fire 200 pulses per second into the edges of the slabs. During those 10 seconds, the slabs heat from room temperature to 130 C, at which point the pumping stops for a quarter of a second as fresh slabs are rotated into place and the hot ones are pressed between heat sinks to cool. Then the cycle repeats.

This design was an ingenious solution to the cooling problem, and the Lawrence Livermore laser reached 25 kW. But the lab didn’t make the cut for the 100-kW round of JHPSSL. Instead, the Army chose two other designs, from Northrop Grumman and from Textron Systems. Rather than moving the slabs, both designs used liquid coolant and heat exchangers to keep the slab temperatures uniform. The big difference between the Northrop Grumman and Textron systems was in the optical layout.

To appreciate how different these designs were, you need to understand that a laser is an oscillator with photons bouncing back and forth between a pair of mirrors. Those photons stimulate the laser crystal to emit more photons of the same wavelength and phase, which is to say that their electric and magnetic fields oscillate in lockstep. There are two ways to boost laser power: The first is just to build a bigger oscillator with more laser material. The second is to amplify the beam by passing it through a more-excited laser material without mirrors.

Northrop Grumman chose the latter method—amplification. The output of a single oscillator was split between two amplifiers to generate a total of 27 kW for 350 seconds, longer than JHPSSL’s stated 300-second goal. For the 100-kW demonstration, Northrop redesigned the amplifiers so that each generated 15 kW and fit onto a table 1 meter square. Reaching 100 kW required splitting the oscillator output among seven amplifiers, then carefully matching the phases of the waves coming out of each in the final beam.

In March of this year Northrop Grumman crossed the finish line, generating a single 105-kW beam for more than 5 minutes and turning 19.3 percent of the input electrical power into output photons. The company’s JHPSSL test bed weighed in at 7 metric tons and measured 2 by 2 by 2.7 meters, but Northrop Grumman engineers have also developed a compact version called Firestrike. Its 15-kW amplifier modules fit into field-ready boxes measuring 30.5 by 58.4 by 101.6 cm, and seven of them stack to make a 100-kW weapon that will weigh only a quarter as much as the test bed. That includes power supply and cooling equipment but not the electronics that adjust the output phases and direct the combined beam toward the target.

Textron avoids the problem of combining beams by building one big oscillator. “We have a single beam running through six slab modules in series,” says Textron’s John Boness, who oversees the company’s laser program. The light follows a zigzag path through the water-cooled slabs, passing through more laser material and collecting more light than if it had traveled in a straight line.

Meanwhile, DARPA has its own program for a slab-laser weapon, called the High Energy Liquid Laser Area Defense System (HELLADS). Using an arcane design from General Atomics in which some of the light passes through the coolant, developers are gunning for a 150-kW laser weapon weighing only 750 kilograms. At only 5 kilograms per kilowatt, the HELLADS laser module would require only 40 percent of the weight of Northrop Grumman’s Firestrike for each kilowatt of output, meaning that HELLADS could actually work aboard a fighter jet.

Illustrations: Steve Stankiewicz

Yet it’s a long way from there to delivering a weapon that can blow enemy rockets out of the sky. The Army must test a 100-kW beam against realistic targets, and developers must build compact versions for field use.

Why didn’t Zeus make the cut for JHPSSL? In Zeus, and in many industrial lasers, the light-emitting material is a special type of optical fiber in which a central core containing light-emitting atoms is surrounded by a layer that guides the pump light along the fiber. This design can convert up to 30 percent of the input power to laser output. Fiber lasers are able to run 24/7 on production lines.

For these reasons, fiber lasers have been getting a lot of attention. Their higher efficiency promises smaller and more portable lasers, and perhaps most important, fibers have larger surface areas than do slabs, making them easier to cool.

Part of the efficiency advantage comes from the fiber structure itself, which increases the fraction of the pump light absorbed. Fiber lasers are more rugged than slabs because they don’t have to send their light through discrete optical components, which can drift out of alignment. Their toughness has made them a winner in industry and piqued the interest of DARPA.

But fiber lasers have their own limits. A single fiber laser can’t combine high power and high beam quality, and no single-fiber laser can reach 100 kW. The light-guiding cores that transmit the light are small and can carry only a limited amount of light before photon interactions steal energy from the beam. By spreading the power over a wide range of wavelengths, an industrial fiber manufacturer, IPG Photonics Corp., in Oxford, Mass., has reached 6.5 kW with a 10-µm-wide core. Fiber lasers with larger cores can reach higher powers—50 kW—but with poorer beam quality.

However, some experts question whether 100 kW is essential. “It’s an urban legend that if you can’t get to 100 kilowatts, you won’t have utility,” says Mike Booen, vice president of advanced missile defense and directed-energy weapons for Raytheon Missile Systems. Even a single industrial fiber laser delivering tens of kilowatts can be of some military use. “In 2006 we blew up two 60-millimeter mortars at a little over 500 meters” with a 20¿¿¿kilowatt commercial laser, he says.

Indeed, Raytheon has integrated a 50¿¿¿kW commercial fiber laser into a customized version of its Phalanx Gatling gun. It’s a brute-force laser with a lot of power and a mediocre beam. But it’s also rugged. Raytheon wanted a laser reliable and robust enough to put in a real war-fighting environment, Booen says, “and not have guys in white coats running around and coaxing it to work.” So far, Booen is happy with this laser’s operation: “You push a button and it comes on.”

Boeing has also tested a kilowatt-class industrial laser in its own multirole weapon system, the Humvee-mounted Avenger. Lee Gutheinz, who directs the high-energy laser program at Boeing Missile Defense Systems, believes that the compact size and inherent ruggedness of fiber lasers makes them attractive for small mobile platforms like a Humvee. But he can’t see how to reach the 100-kW level. “Extending the capability of fiber lasers at reasonable performance above tens of kilowatts hurts my head,” he says. “I don’t want to say it can’t be done, but it’s very hard.”

Will solid-state laser weapons be like flying cars that never get off the ground? On one hand, grim headlines continually point out the need for a defense against rockets, artillery, and mortars. And tests have shown that such targets are vulnerable to laser heating. Solid-state lasers are far more practical for battlefield use than scaled-down versions of ABL.

On the other hand, a panel of experts convened by the National Research Council warned the Army last September that high-energy solid-state lasers were not yet ready for battle. And these experts also urged the Army to push beyond 100 kW to demonstrate a 400-kW laser, which they expect to be a more potent weapon, by 2018.

THEL showed that a laser beam can destroy rockets, missiles, and artillery, but success depends on atmospheric effects and target interactions as well as raw power, and those factors depend on wavelength. With solid-state lasers emitting at 1 µm, far from the proven 3.8-µm wavelength of THEL, the Army’s upcoming test shots with a 100-kW solid-state laser are therefore essential. But controlled tests alone won’t demonstrate military effectiveness. The battlefield is a harsh environment, says Philip Coyle, senior advisor at the Center for Defense Information and a former director of testing for the Pentagon, and no laser systems “are ready for realistic operational testing.”

Missile defense may be an appealing idea, but “it is virtually impossible to build defensive laser systems that are cost-effective,” says Coyle. He says the key question is whether it is cheaper for the Army to improve its defenses or for the enemy to overwhelm them with more missiles.

Nonetheless, the Pentagon thinks solid-state lasers have a better shot at short-range missiles on the battlefield than the Airborne Laser has for long-range missile defense. In early April U.S. Secretary of Defense Robert Gates announced plans to downshift development of ABL, saying that its “affordability and technology problems” made the program’s operational role “highly questionable.” ABL will likely not be scrapped entirely but will stay in an indefinite R&D phase. So for that laser weapon at least, the flying-car question seems destined to remain open for a long time.

To Probe Further

Read the military fact sheet for the Airborne Laser at https://www.mda.mil/mdalink/pdf/laser.pdf.

An IEEE Spectrum feature in 2005 outlined the government’s proposed plans for space-based missile defense using directed energy. The article is available at /energy/nuclear/starcrossed. An abbreviated version of the National Research Council’s report, “Directed Energy Technology for Countering Rockets, Artillery, and Mortars (RAM)” is available at https://books.nap.edu/catalog.php?record_id=12008.