13 June 2012—Liquid crystal displays dominate today’s big, bright world of color TVs. They are inefficient, though, and don’t produce the vibrant, richly hued images of organic light-emitting diode (OLED) screens, which are expensive to make in large sizes.

But a handful of start-up companies have been plugging away at another display technology that could enhance LCDs and unseat OLEDs: quantum dots. These light-emitting semiconductor nanocrystals shine pure colors when excited by electric current or light and promise rich, beautiful displays that would be inexpensive and easy to manufacture.

At Display Week, an industry meeting run by the Society for Information Display, quantum-dot developer Nanosys announced that it is working with 3M to commercialize a quantum-dot film that could be integrated into the back of today’s LCD panels. The film could cut the display’s power consumption by half and enable LCDs to generate 50 percent more colors within the range set by the National Television System Committee. Nanosys’s CEO, Jason Hartlove, says that major LCD manufacturers are now testing the film, and a 17-inch notebook incorporating the technology should be on shelves within six months. “We’ve designed this technology to give LCD manufacturers a competitive counterweight to OLEDs,” he says.

New LCD TVs typically have a strip of white LED backlights along the panel’s edge. Light guides spread the illumination evenly across the panel; the light then passes through a series of optical films that colorize, polarize, and diffuse it. The resulting red, green, and blue hues are mixed at different intensities to produce the display’s color gamut. More pure, saturated red, green, and blue yield a wider range, rendering more-lifelike images. But with today’s technology, “the broad-spectrum white has a bunch of pinks, yellows, and oranges,” Hartlove says. “So when you create a red from a color filter, you let in a bunch of different reddish colors.”

The process is also extremely inefficient: More than 90 percent of the light from the white LEDs (which are really blue LEDs coated in yellow phosphor) is wasted as it passes through the optical film stack.

Nanosys’s quantum-dot film effectively acts as the phosphor that converts some of the light from highly efficient blue LEDs to spectrally pure red and green, resulting in a broad color gamut. And it shouldn’t add extra cost. “This technology just drops in and is compatible with existing LCD manufacturing methods,” Hartlove says. “And we only use blue LEDs, which are half the cost of white.”

Lexington, Mass.–based QD Vision, an MIT spin-off and the first to market a quantum-dot consumer product, is developing its own LCD backlight technology. Its technology, literally and figuratively, has an edge over Nanosys’s, says CTO Seth Coe-Sullivan. Instead of using a large film of quantum dots, its product would integrate the quantum dots into the LED array on the panel’s edge. “The efficiency and stability of quantum dots degrades at higher temperatures. We’ve made ours to handle the higher temperature at the backlight. So we use 1/100 of the material, which is not inexpensive.”

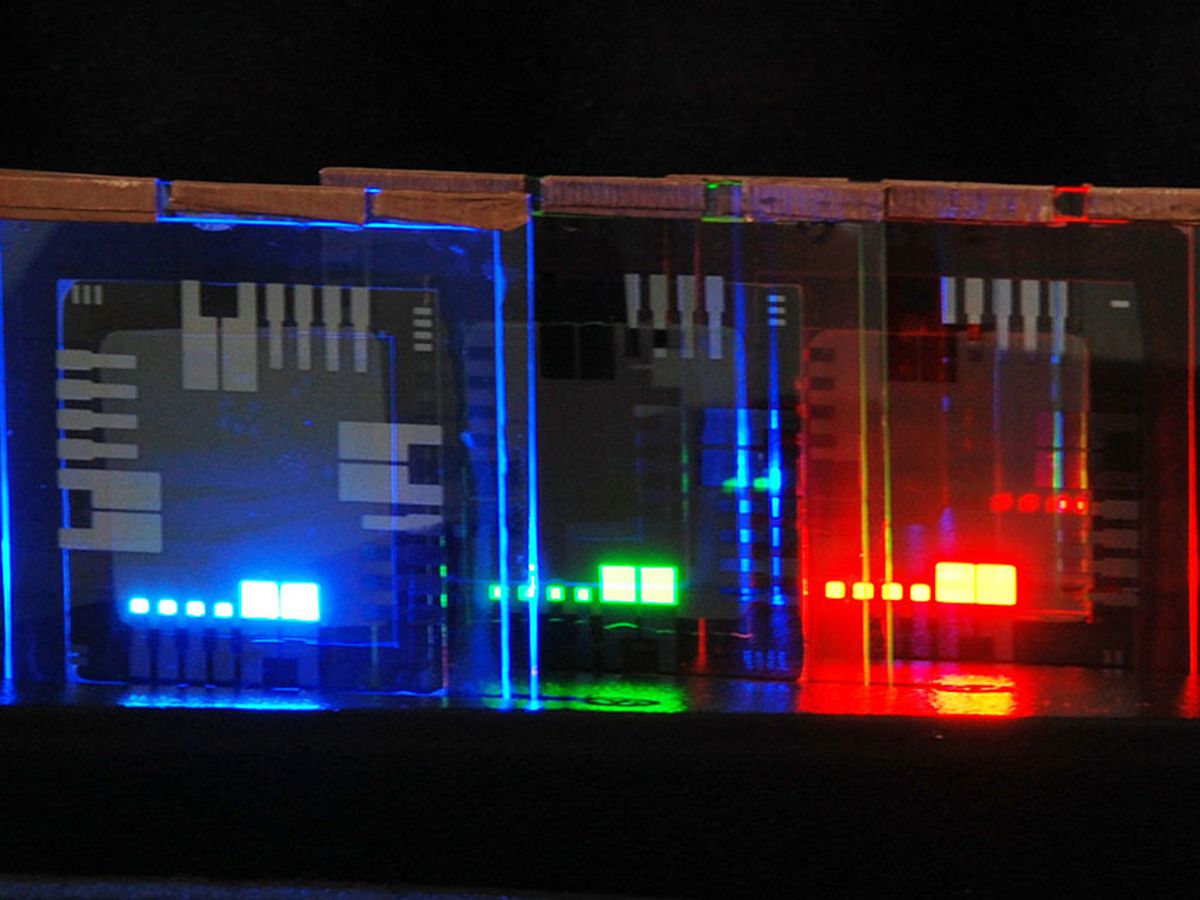

QD Vision is also working on another exciting product: a quantum-dot LED display that works exactly like an OLED display but at a lower cost. OLED displays contain a thin layer of light-emitting organic semiconductor sandwiched between two electrodes. QD Vision replaces the organic material with quantum dots.

Manufacturing OLED displays typically requires depositing organic molecules on the substrate using expensive evaporation techniques. There are cheaper ways to deposit the materials, such as inkjet printing, but those methods compromise the quality of the molecules. Quantum dots, on the other hand, can be easily suspended in solvents to make inks that can be stamped or printed without losing their glowing prowess. Quantum dots are also intrinsically better than organic semiconductors at converting electricity to light, so they use less energy to shine just as brightly.

QD Vision demonstrated the first full-color, 4-inch-diagonal quantum-dot LED display prototype at Display Week last year. The company has teamed up with LG Display to commercialize the technology, and Coe-Sullivan expects the first products in three to five years. Samsung, meanwhile, is also pursuing quantum-dot LED displays. Last year, researchers at the Samsung Advanced Institute of Technology reported a 4-inch-diagonal color display made on glass and plastic.

Quantum dots, both in LCD backlight films and as light emitters, might still face tough competition from OLEDs. So far, OLED displays have been relegated to small smartphone screens, but this year LG and Samsung unveiled the first 55-inch OLED TV-screen prototypes. Samsung claims that it will launch a commercial version later in 2012 in South Korea, at a price of US $9000—10 times as expensive as LCD sets—but the cost could drop as the technology improves. “There [have] been decades of work on organic emissive material, and there have been a lot of improvements,” says Paul Semenza, a senior analyst at research firm DisplaySearch. “It’s not like quantum dots are competing against a new thing.”

Semenza says that the success of quantum-dot display technology will depend in part on developments in OLEDs and LEDs over the next few years. The LCD backlight approach shows promise because it’s easy and shows visible improvements, but “as white LED backlights improve, the benefit from doing this might diminish,” he says. OLEDs, meanwhile, are already beautiful but costly to manufacture. “If quantum-dot displays are easy to manufacture [and] have a lower cost process and better efficiency, they could be big.”

This article was updated on 17 July 2012.

About the Author

Prachi Patel is a contributing editor to IEEE Spectrum and a freelance journalist in Pittsburgh. In the June 2012 issue she laid out the case for engineers getting an MBA in Europe.