In big cities, sometimes buildings that don’t have a lot of roof space for solar cells still have large windows that could harness light for electricity. Researchers at the Los Alamos National Laboratory, in New Mexico, reported yesterday in Nature Energy that a thin film of quantum dots on everyday glass could be the key to achieving acceptable efficiency in window photovoltaic systems at low cost.

Mostly, engineers have tried using modules of connected solar cells to capture sunlight falling on windows. Some wondered if it would be possible to do it with less cells. Taking advantage of a mechanism for capturing the light falling on a window and then directing it to a single solar cell “simplifies the device; it makes it less expensive,” says Victor Klimov, a nanotechnology engineer at Los Alamos.

At first, engineers tried using organic dyes as a way to concentrate the light. The problem with that, Klimov says, is that the dyes absorb the light they produce because it appears very similar to the incoming rays from the sun. In 2013, engineers instead started investigating nanometer-scale semiconductors called quantum dots because they allow customizing properties such as what kinds of light they absorb and which ones they don’t.

In the new research, Klimov and his team found that a thin layer of quantum dots on normal glass could have a lifetime of up to 14 years and about 1.9 percent overall energy conversion efficiency. To make these devices practical they’ll have to reach 6 percent, he says, so they’re getting close.

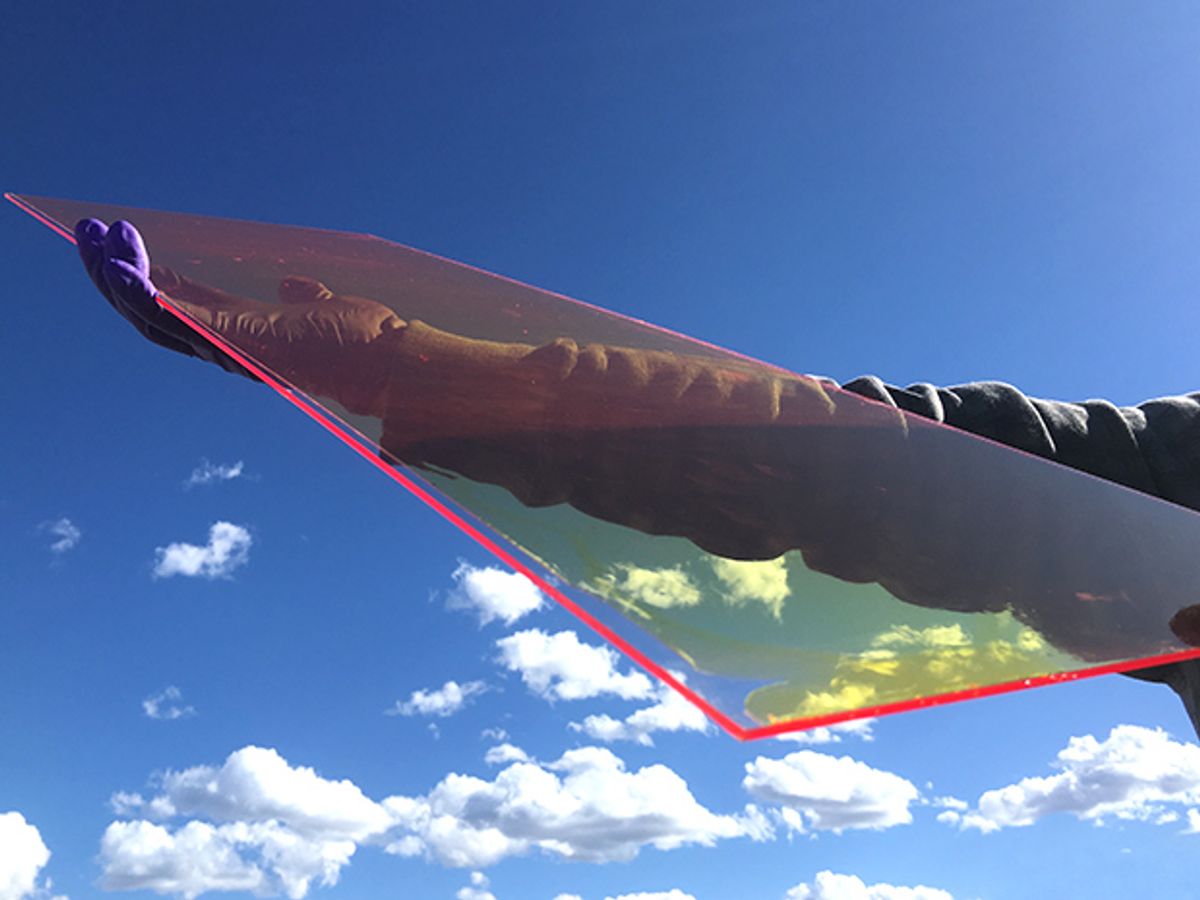

What’s more, adding quantum dots to window glass is surprisingly easy: A machine pours a slurry of quantum dots and PVP polymer onto the glass and a blade spreads it out to form a thin sheet.

The quantum dots consist of a CdSe inner core, a Cd1−xZnxS outer shell, and are coated in silica for protection from oxidation—with the outer shell acting like an absorber. When a photon hits a dot, an electron in the shell is kicked out of its valence band into the conduction band, leaving a hole. The rogue electron and hole jump to the core, where they recombine to produce a new photon with lower energy.

By design, the shell only absorbs high energy photons, and the new photon from the core is free to propagate throughout the glass and quantum dot layers via internal reflections. Eventually, the propagating photons would arrive at the glass edges—where one or more solar cells could pick them up.

In 2015 research, members of the team had tried dispersing quantum dots directly inside a polymer. However, in polymer materials such as this, many of these photons would scatter and escape the material. The optical properties of the new thin quantum-dot layer on glass are such that there’s minimal scattering and the light tends to propagate much longer, Klimov says.

“This is important for showing that these nanocrystals may be used to make large-area and cost-effective diffuse light concentrators,” Vivian Ferry, an energy and electronics researcher at the University of Minnesota who was not involved in the study, but has worked with solar cells and quantum dots, writes in an email.

When the researchers tested absorption and stability properties, they also found the manufactured device held its own.

“If you’re serious about applications,” Klimov says, “Stability must be comparable to the stability of the solar cell.”

He believes the application technique is inexpensive and accessible enough for the glass industry to use. A coating could even be scraped off and re-used.

Still, there’s plenty of work to do before reaching the break-even point on energy conversion, he says. To meet the efficiency goal, he’s now tinkering with the concentrations of quantum dots used and their absorption properties.

For comparable light concentrators of a similar size, color, and transparency, the Los Alamos system is “pretty good,” writes David Patrick, an energy researcher at Western Washington University who was not involved in the study but has worked on solar light conversion.

A correction to this article was made on 11 October 2016. The inner core and outer shell materials were inadvertently reversed.