Few people have seen their handiwork influence the world more than Bill Mensch. He helped create the legendary 8-bit 6502 microprocessor, launched in 1975, which was the heart of groundbreaking systems including the Atari 2600,Apple II, and Commodore 64. Mensch also created the VIA 65C22 input/output chip—noted for its rich features and which was crucial to the 6502's overall popularity—and the second-generation 65C816, a 16-bit processor that powered machines such as the Apple IIGS, and theSuper Nintendo console.

Many of the 65x series of chips are still in production. The processors and their variants are used as microcontrollers in commercial products, and they remain popular among hobbyists who build home-brewed computers. The surge of interest inretrocomputing has led to folks once again swapping tips on how to write polished games using the 6502 assembly code, with new titles being released for the Atari, BBC Micro, and other machines.

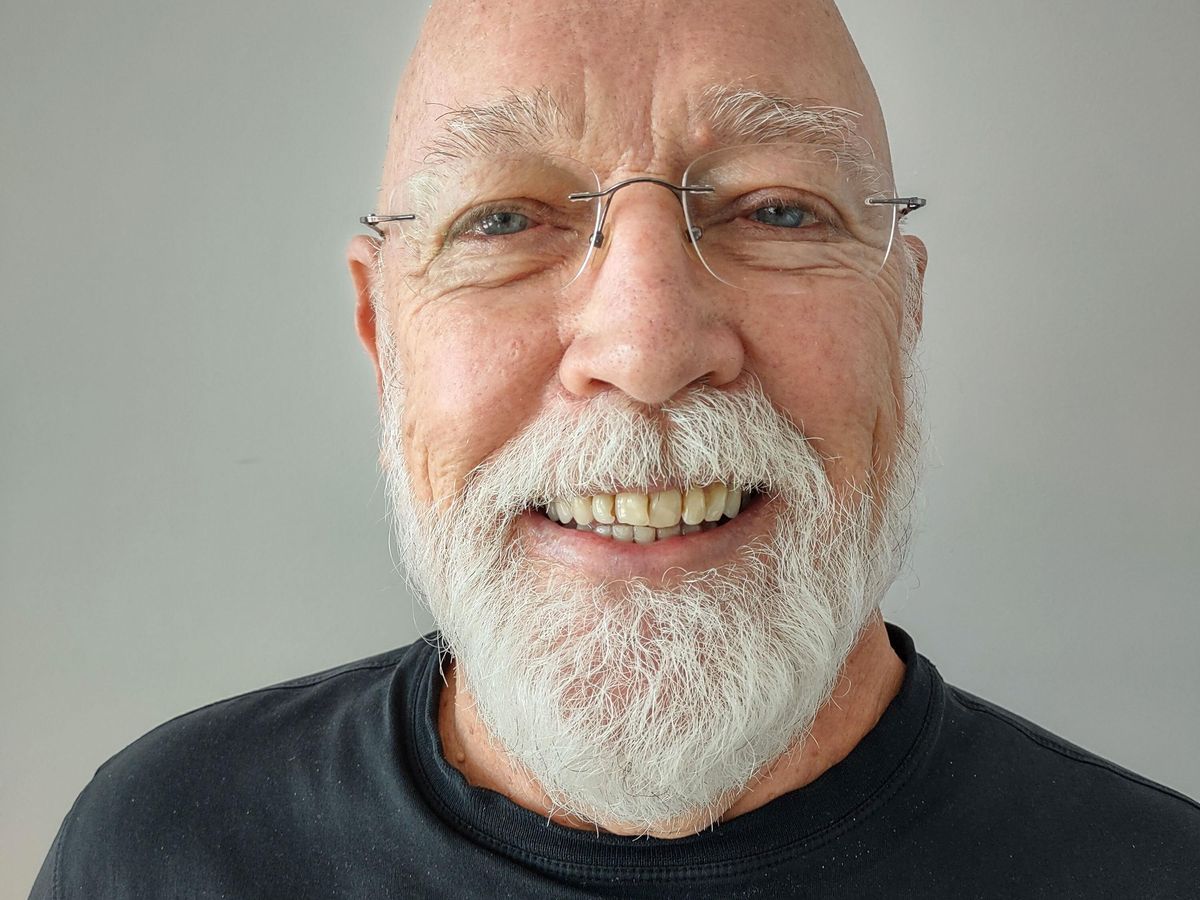

Mensch, an IEEE senior life member, splits his time between Arizona and Colorado, but folks in the Northeast of the United States will have the opportunity to see him as a keynote speaker at the Vintage Computer Festival in Wall, N.J., on the weekend of 8 October. In advance of Mensch's appearance, The Institute caught up with him via Zoom to talk about his career.

This interview had been condensed and edited for clarity.

The Institute: What drew you into engineering?

Bill Mensch: I went to Temple University [in Philadelphia] on the recommendation of a guidance counselor. When I got there I found they only had an associate degree in engineering technology. But I didn't know what I was doing, so I thought: Let's finish up that associate degree. Then I got a job [in 1967] as a technician at [Pennsylvania TV maker] Philco-Ford and noticed that the engineers were making about twice as much money. I also noticed I was helping the engineers figure out what Motorola was doing in high-voltage circuits—which meant that Motorola was the leader and Philco was the follower. So I went to the University of Arizona, close to where Motorola was, got my engineering degree [in 1971] and went to work for Motorola.

TI: How did you end up developing the 6502?

BM:Chuck Peddle approached me. He arrived at Motorola two years after I started. Now, this has not been written up anywhere that I'm aware of, but I think his intention was to raid Motorola for engineers. He worked with me on the peripheral interface chip (PIA) and got to see me in action. He decided I was a young, egotistical engineer who was just the right kind to go with his ego. So Chuck and I formed a partnership of sorts. He was the system engineer, and I was the semiconductor engineer. We tried to start our own company [with some other Motorola engineers] and when that didn't happen, we joined an existing [semiconductor design] company, called MOS Technology, in Pennsylvania in 1974. That's where we created the 6501 and 6502 [in 1975], and I designed the input/output chips that went with it. The intention was to [develop a US $20 microprocessor to] compete with the Intel 4040 microcontroller chipset, which sold for about $29 at the time. We weren't trying to compete with the 6800 or the 8080 [chips designed for more complex microcomputer systems].

TI: The 6502 did become the basis of a lot of microcomputer systems, and if you look at contemporary programmer books, they often talk about the quirks of the 6502's architecture and instruction set compared with other processors. What drove those design decisions?

BM:Rod Orgill and I had completed the designs of a few microprocessors before the 6501/6502. In other words, Rod and I already knew what was successful in an instruction set. And lower cost was key. So we looked at what instructions we really needed. And we figured out how to have addressable registers by using zero page [the first 256 bytes in RAM]. So you can have one byte for the op code and one byte for the address, and [the code is compact and fast]. There are limitations, but compared to other processors, zero page was a big deal.

There is a love for this little processor that's undeniable.

TI: A lot of pages in those programming books are devoted to explaining how to use the versatile interface adapter (VIA) chip and its two I/O ports, on-board timers, a serial shift register, and so on. Why so many features?

BM: I had worked on the earlier PIA chip at Motorola. That meant I understood the needs of real systems in real-world implementations. [While working at MOS] Chuck, Wil Mathis, our applications guy, and I were eating at an Arby's one day, and we talked about doing something beyond the PIA. And they were saying, "We'd like to put a couple of timers on it. We'd like a serial port," and I said, "Okay, we're going to need more register select lines." And our notes are on an Arby's napkin. And I went off and designed it. Then I had to redesign it to make it more compatible with the PIA. I also made a few changes at Apple's request. What's interesting about the VIA is that it's the most popular chip we sell today. I'm finding out more and more about how it was used in different applications.

TI: After MOS Technology, in 1978 you founded The Western Design Center, where you created the 65C816 CPU. The creators of the ARM processor credit a visit to WDC as giving them the confidence to design their own chip. Do you remember that visit?

BM: Vividly! Sophie Wilson and Steve Furber visited me and talked to me about developing a 32-bit chip. They wanted to leapfrog what Apple was rumored to be up to. But I was just finishing up the '816, and I didn't want to change horses. So when they [had success with the ARM] I was cheering them on because it wasn't something I wanted to do. But I did leave them with the idea of, "Look, if I can do it here … there are two of you; there's one of me."

TI: The 6502 and '816 are often found today in other forms, either as the physical core of a system-on-a-chip, or running on an FPGA. What are some of the latest developments?

BM: I'm excited about what's going on right now. It's more exciting than ever. I was just given these flexible 6502s printed with thin films by PragmatIC! Our chips are in IoT devices, and we have new educational boards coming out.

TI: Why do you think the original 65x series is still popular, especially among people building their own personal computers?

BM: There is a love for this little processor that's undeniable. And the reason is we packed it with love while we were designing it. We knew what we were doing. Rod and I knew from our previous experience with the Olivetti CPU and other chips. And from my work with I/O chips, I knew [how computers were used] in the real world. People want to work with the 65x chips because they are accessible. You can trust the technology.

- 25 Microchips That Shook the World - IEEE Spectrum ›

- The Truth About Bender's Brain - IEEE Spectrum ›

- 10 Gifts For Retrocomputing Fans ›

- Creating the Commodore 64: The Engineers’ Story - IEEE Spectrum ›

- Two C64s Plus a Pile of Floppy Disks Equals One Accordion - IEEE Spectrum ›

Stephen Cass is the special projects editor at IEEE Spectrum. He currently helms Spectrum's Hands On column, and is also responsible for interactive projects such as the Top Programming Languages app. He has a bachelor's degree in experimental physics from Trinity College Dublin.