Of the 20 countries with the lowest supplies of electricity in the world, 19 are in sub-Saharan Africa, where on average fewer than one in three people have electricity. Instead, for light, they use candles and kerosene lamps, which are harmful to their health. And once the wax or fuel runs out, they sit in darkness. According to a 2014 report from the International Energy Agency, growing the energy sector in that region would be the key to its prosperity.

IEEE Smart Village—formerly the IEEE Community Solutions Initiative—has some bold ideas on how to bring electricity to millions while also providing jobs to the community. It is a signature program of the IEEE Foundation, which provides funds for projects that can yield an immediate, and broad, impact and are sustainable over the long term.

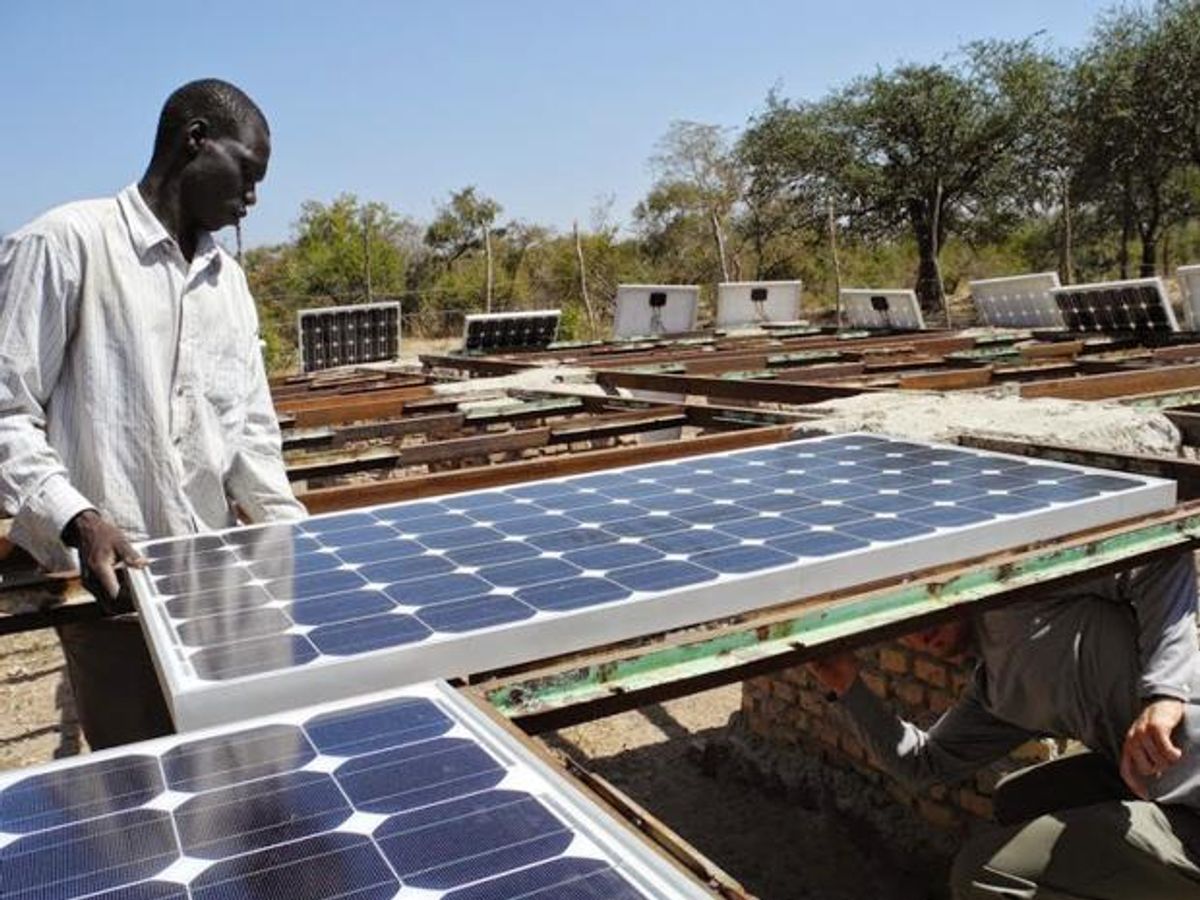

Smart Village members work with local entrepreneurs in several countries, including Cameroon and Nigeria, to help them set up micro-utilities, using renewable energy technology like solar panels to power nearby homes, businesses, and schools. Depending on resources, they could serve dozens of customers or up to tens of thousands, charging them a monthly fee comparable to the cost of kerosene and candles.

IEEE grants the initial investment for buying the equipment, as well as providing mentoring and training. So far, since development of the micro-utilities began in 2011, the program has supplied electricity to some 15,000 people.

“Our goal is to provide electricity for 50 million people in 10 years, and that’s conservative,” says IEEE Fellow Robin Podmore, cofounder of IEEE Smart Village. He believes it’s doable because the right entrepreneurs and partners are out there. He adds that in the last few years, philanthropists and investors have realized that helping locals form their own businesses is the key to lifting them out of poverty, and is far more sustainable and effective than donations alone.

A SUSTAINABLE MODEL

The earthquake that struck Haiti in 2010 was the genesis for what was then IEEE’s Community Solutions Initiative. IEEE volunteers, moved by the disaster, worked to develop a reliable source of low-cost electricity there. They came up with the SunBlazer community charging stations.

Using six silicon photovoltaic 250-watt solar panels, the trailer can collect more than 4 kilowatt-hours of energy per day, enough to charge 80 portable battery packs. These packs can then be used to power LED light bulbs and are equipped with USB ports to charge cellphones—which many in remote regions now depend on for exchanging money as well as for education and health services. Locals pay US $6.50 a month for unlimited charging.

Since then, community charging stations have been set up not only in Haiti but also in Cameroon, Kenya, Nigeria, and South Sudan. IEEE volunteers help train operators to install the technology and mentor them on how to run a profitable business, including managing payments from their customers. In Cameroon, for example, IEEE Smart Village formed a partnership with the Torchbearers Foundation, which provides electric systems to their communities. It is starting a school to train entrepreneurs on assembling the SunBlazer systems locally.

And in Nigeria, entrepreneurs have built microgrids, lighting up nearby homes and businesses from a single solar energy source. To accomplish this, they used traditional electrical wiring to connect multiple customers within a limited geographic area. They are all able to power their homes at the same time.

Another innovation being tested through IEEE Smart Village includes LightCycle, a pedal-powered generator that connects a bicycle to a 12-V DC generator. One hour of pedaling can produce 40 watt-hours of power and can be stored in portable battery packs for customers to use.

Currently, IEEE Smart Village is helping to support efforts in South Sudan with entrepreneur Mou Riiny, a former refugee from that war-torn country. Riiny was brought to the United States as a child and was raised by foster families. He earned an electrical engineering degree from the University of San Diego. He recently returned to his village, Thiou, where he is installing 13 community charging stations powered by solar panels. Each station will serve 100 portable battery kits. They will be up and running later this year.

THE NEXT ROUND

Local entrepreneurs will be able to apply to get funding through the IEEE Smart Village website in late 2015. Applicants must submit a detailed business plan, which includes how they will make their utilities sustainable after IEEE’s initial contribution. They also must describe how their profits will be reinvested in the local communities and create jobs.

“Providing electricity can help others in the community to form businesses and allow existing ones to stay open longer, which will help shopkeepers and farmers sell goods into the evening,” Podmore says. “By creating jobs, we’re preventing people from having to leave their families and villages to make money.”

The tide is turning, he adds. Instead of leaving, people are now moving to remote regions in Africa to start businesses, particularly in the power and energy sector. “There is just far less competition and a lot of opportunity,” he says. “By changing people’s lives, it’s not unfair for entrepreneurs to make some profit.”

This article is part of our February 2015 special report on Global Development, which highlights IEEE’s efforts in using technology to help advance developing and underserved regions.

This article is also part of our September 2015 special report on startups, which highlights IEEE’s efforts to attract more entrepreneurial types to the organization.

Monica Rozenfeld is a freelance writer and an executive communications strategist for Fortune 100 companies.