Silicon Valley start-up Solar Junction has raised the bar for solar efficiency to 44 percent, and even higher values are in the cards: The company has a road map for reaching 50 percent efficiency and beyond.

To break the efficiency record, Solar Junction built a cell with three regions, known as junctions, that are stacked on top of one another; each absorbs a different spectral region of the sun’s rays. The result is a device that delivers far more energy than conventional cells do. Ordinary photovoltaics have just a single junction. Each junction in the triple-junction cell operates at a different output voltage, and they are connected in series, so the total power produced gets a boost.

Manufacturing a triple junction is not a first, but the type of material that Solar Junction uses for the bottom cell, known as dilute nitride, is new. In this case, the material is made up of gallium indium arsenide antimonide with a splash of nitrogen.

Dilute nitrides have a checkered history. In the middle of the last decade, they were the key ingredient in a new generation of telecom-wavelength lasers that failed to win significant sales. “It wasn’t for yield or lack of performance. It was because the telecom industry crashed, and that choked off any new products,” explains Homan Yuen, Solar Junction’s vice president of research and development.

In triple-junction cells, dilute nitrides are destined to make a big impact because they offer unprecedented versatility, says Yuen. This material’s composition can be tuned to optimize the power that the cell harnesses from the sun’s infrared energy. But what’s really important is that engineers can make those tweaks while independently controlling the spacing of the atoms in the dilute nitride’s crystal. Even tiny mismatches between this nitride’s crystal lattice and that of the layers below and above can crush efficiency.

The 44 percent figure is remarkable on its own, but what’s going to keep Solar Junction’s new cell from just being another one for the record books is that the process can be extended to produce four-, five-, or even six-junction cells. This will increase the output voltage of photovoltaics and ultimately let them yield more power (the product of current and voltage).

The upshot of all this optimization is that the company will be able to boost efficiency past the coveted 50 percent mark, according to Solar Junction engineers, who’ve already mapped out a path to that goal. They will begin by inserting a bottom germanium junction to form a four-junction cell with better performance in the infrared. Further gains will then result from replacing the single dilute nitride layer with a pair of dilute nitride layers, before a sixth junction is added at the top of the structure, which will improve the cell’s ultraviolet efficiency.

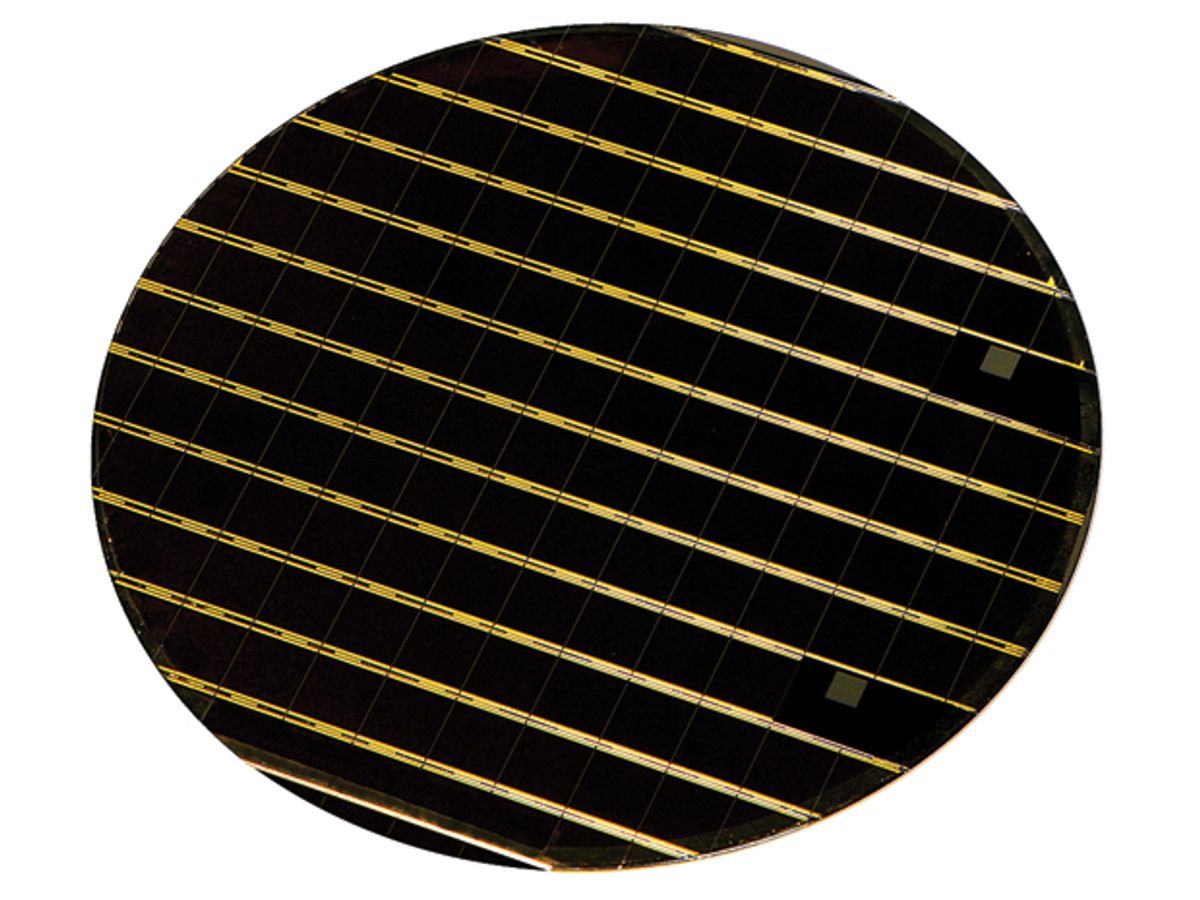

Multijunction cells are very expensive to produce because their structure is formed using painfully slow deposition techniques on small, costly substrates. So to make the photovoltaic systems that use them cost-competitive with those based on silicon, you need mirrors and lenses to focus sunlight, concentrating it by a factor of several hundred onto cells no bigger than a fingernail.

Concentrating sunlight not only trims costs, it also boosts cell efficiency, because it increases the output voltages at each junction. In Solar Junction’s case, the record-breaking efficiency resulted from concentrating sunlight by a factor of 947 on a cell from a production run.

Installations of photovoltaic systems based on this technology must swivel and tilt from dawn to dusk to ensure that sunlight always hits an array of cells head-on. Despite that complexity, such PV systems are quickly becoming more popular in dry, sunny climes. According to IMS Research, in Wellingborough, England, 90 megawatts will be deployed in 2012, rising to 1.2 gigawatts by 2016. This rapid growth is spurred by the low cost of the energy that these systems generate over their lifetime. The multijunction PV systems can undercut silicon cells by 12 percent in some locations, and at the efficiencies Solar Junction is now seeing, this gap could widen.

“Cells are one of the main contributors to the total system costs,” explains Jemma Davies of IMS. “By increasing efficiency and concentration, the output per cell is increased, and the cost per watt decreases.”

Contributing Editor Richard Stevenson specializes in the reporting of advances in compound semiconductor devices, such as LEDs, lasers, high-efficiency solar cells and next-generation power electronics. In the early 2000s he gained valuable experience in the compound semiconductor industry, working as a process engineer for IQE. During a three-year stint at this company he oversaw the growth and characterization of a vast range of thin films of compound semiconductor materials. In 2005 he changed tack, embarking on a career in journalism. He began with the role of Features Editor of Compound Semiconductor magazine, and took over as the Editor of this publication in 2009. Stevenson holds a Ph.D. in optolectronics from the University of Cambridge, and a Master of Physics degree from the University of Southampton.