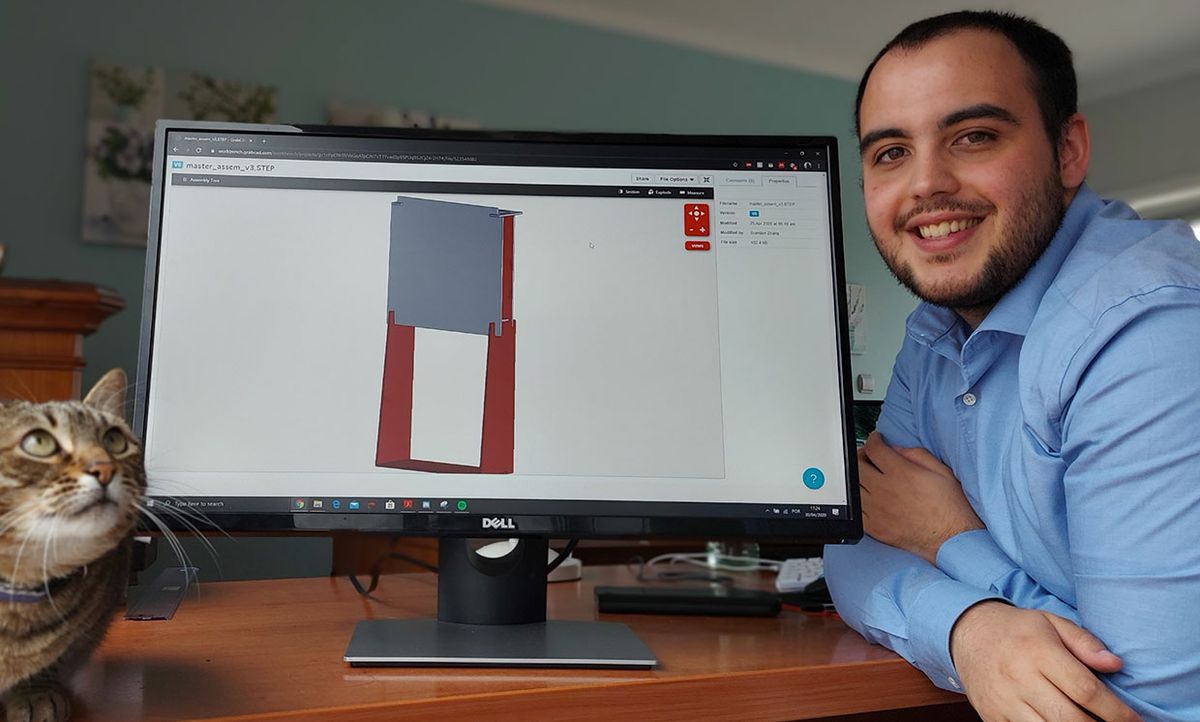

THE INSTITUTE IEEE Student Member Pedro Brandao is part of a team of engineering students at the University of Porto in Portugal, that has built a device to screen people for fever before they enter facilities such as airports, office buildings, schools, and stores.

Brandao is pursuing a Ph.D. in mechanical engineering at the university.

The Instituteasked him about the project.

This interview has been edited and condensed for clarity.

What problem are you trying to solve?

We are trying to help stop the spread of COVID-19 and reduce the risk of infection by developing an affordable device that can perform non-contact temperature measurement.

What technologies are you using?

The station contains a medical-grade infrared temperature sensor and ultrasonic distance sensors held up by two metal rods that sit on a base. We used a 3D printer and laser cutting to make the base, case, and rods.

A person would stand in front of the station. The ultrasonic distance sensors— which measure the distance to an object using ultrasonic sound waves—alerts the system that a person is present. The temperature sensor, obtained from open-source electronics platform Arduino, reads the person’s temperature.

Explain how your device works.

The device is mounted on a wall outside of a building or public space. There will be markings on the ground that direct people where to stand—about 20 centimeters away from the station.

The infrared temperature sensor measures the person’s temperature and the reading is displayed on a screen that is mounted next to the device. If the reading is high, a message instructs the person to get a COVID-19 test. The entire process takes under 20 seconds.

What challenges have you faced and how did you overcome them?

Designing a machine that is easy and affordable to build.

We found a local community workshop where we could build our device. These public places allow people free access to tools such as 3D printers, laser cutters, and lathes. We used its tools, and the low-cost electronics that we purchased.

How close are you to the final product?

We are planning to begin testing the prototype soon.

Testing will include verifying the accuracy of the temperature sensor and assuring that each device can be easily made by other engineers.

To help us ensure accuracy, we are working to find a manufacturer or government lab that can provide us with blackbody infrared temperature sensors. Blackbody infrared temperature sensors measure the thermal electromagnetic radiation within or surrounding a body at room temperature and are more accurate than other sensors.

How many people are involved?

The team consists of more than 20 people who work in a variety of disciplines such as electronic engineering, optical engineering, and healthcare.

How can other IEEE members get involved?

The team communicates mainly on our slack channel. IEEE members can join by searching: #project-temperature-detection. Members can also emailme.

Attention IEEE members: are you part of a team responding to the COVID-19 crisis? We want to hear from you! Wherever you are and whatever you are doing, if you are helping deal with the outbreak in some way, let us know. Send us accounts of anywhere from 200 to 800 words, or simply give us a rough idea of what you are doing and your contact information. Write to: k.pretz@ieee.org