Portable devices are helping maintenance and operations professionals throughout the process industry sector work more efficiently by monitoring multiple systems, lowering costs, and improving product quality.

For example, portable hygrometers can quickly monitor a plant’s compressed air supply system and verify air dryer performance by accurately measuring dewpoint.

Uncontrolled moisture in your air supplies may damage pneumatic controls, tooling, and finished products. To combat this, regenerative desiccant dryers such as pressure swing and heater type, as well as refrigerant dryers are often used to remove or reduce moisture from compressed air supplies.

For spot-check measurements, a hand-held, battery-operated, portable hygrometer can be specified. These devices enable technicians to verify air dryer performance on the factory floor, as well as check the accuracy of the dewpoint sensor installed on the dryer. The devices can also measure moisture at any point throughout the plant’s compressed air system.

In addition to its on-line (stationary) dewpoint measurement instruments, Kahn Instruments offers two portable hygrometer models that not only monitor your air dryer, but also spot-check your air system throughout the plant. This means that you can observe – not guess – your facility’s air system performance. Better dewpoints result in:

Improved system efficiency

Less dryer usage

Lower energy costs

Using either an on-line or portable hygrometer to measure moisture content at the dryer outlet offers a way to track dryer performance.

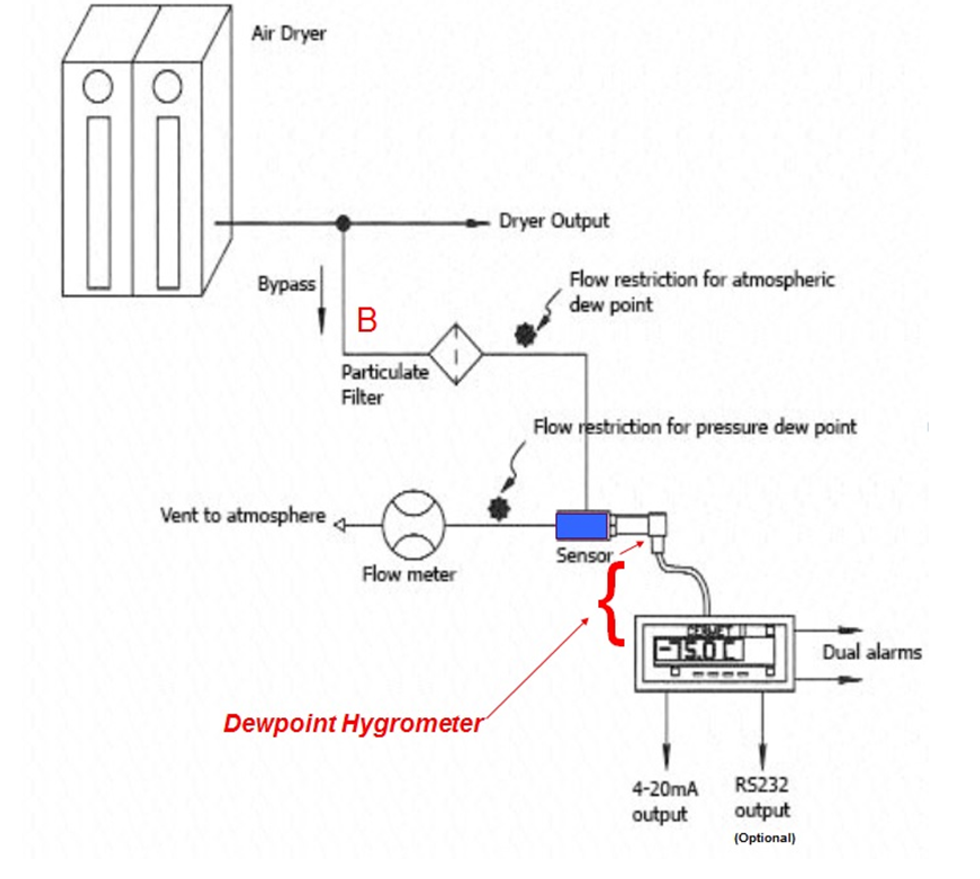

Two primary compressed air sampling methods, Direct Insertion or a Sampling System, are used in moisture measurement. The preferred sampling method for either an on-line or a portable hygrometer is the Sampling System. In this method (shown in the accompanying diagram with an on-line hygrometer), measurements may be made either at full line pressure or at atmospheric pressure, depending on preferred working practice. In certain cases, properly positioning the flowmeter and pressure regulator will facilitate measurement. An appropriately scaled flowmeter after the sensor continuously indicates that an adequate flow rate is achieved across the sensor. Sampling arrangements for a portable hygrometer would be much the same, and Kahn Instruments can provide ready-made solutions with its portable hygrometers.

Figure 1: Compressed air dryer dewpoint measurement location. (Source: Kahn Instruments, Inc.)

Kahn’s Easidew Plus Portable Hygrometer measures a dewpoint range from -58F to +68F in a compact NEMA 6 enclosure. Kahn’s HygroPort Portable Hygrometer measures dewpoint from -148F to +68F with an accuracy of +/-2C, is Bluetooth wireless enabled, and can log more than 300,000 data points. Two versions are available, a HygroPort (standard) and a HygroPort IS (intrinsically safe) for measurements in natural gas and other hazardous gases or hazardous locations.

These portable devices—plus Kahn’s range of quality stationary hygrometers—enable professionals in industries from semiconductors to electric power generation combat moisture and improve efficiency.