3 May 2012—Increasingly concerned about counterfeit electronics in its supply chain, the U.S. Department of Defense is attacking the problem on two fronts: It’s cracking down on defense contractors to increase their vigilance, and it’s looking for new technologies to fight the counterfeiters.

A leading new technology in the struggle against counterfeiters comes from an odd source: plants. The Defense Logistics Agency (DLA), which procures materials and parts for the U.S. military, is working with Applied DNA Sciences, in Stony Brook, N.Y., which has developed a technique that uses plant DNA to authenticate chips and other components. Other industries currently use the technology to authenticate luxury goods, textiles, and currency.

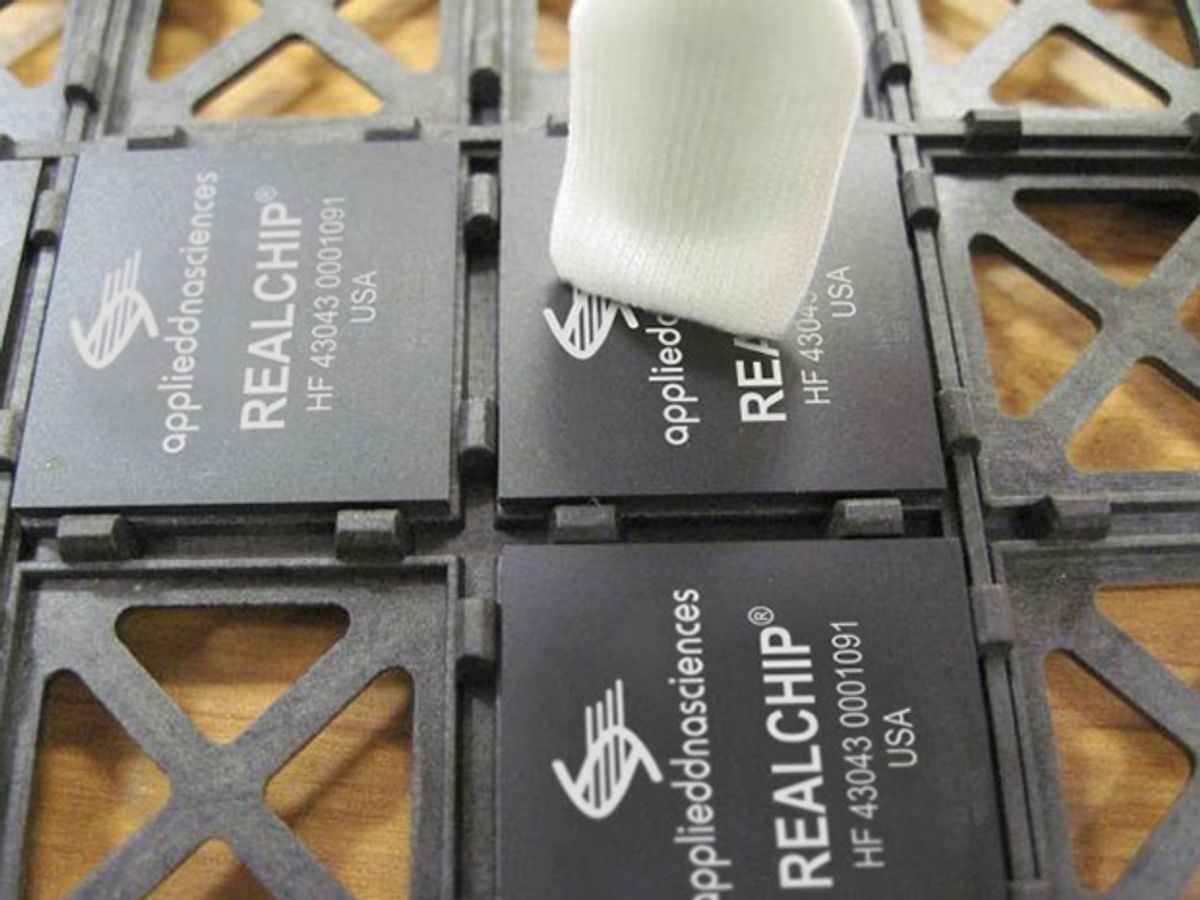

Applied DNA starts with botanical genomic sequences, then scrambles the genetic code using a proprietary technique. It then synthesizes DNA with the scrambled code and incorporates that into a product or its packaging—say, by mixing it with ink and stamping it on a package. Once the DNA mark is applied to a product, users can detect it because it fluoresces under certain light. Products can also be checked by swabbing the DNA mark and sending the sample to Applied DNA, which authenticates the mark using standard genetic-sequencing techniques. Only those with knowledge of the scrambled sequence can verify the mark, making it impossible to fake.

“Everyone along the supply chain is guaranteed authenticity—the manufacturer, the distributor, the board builders,” says Janice Meraglia, vice president of military and government programs at Applied DNA.

In tests for the DLA, Applied DNA demonstrated that its DNA marks could survive the heat and other stresses of the semiconductor production process. A second round of tests, now under way, will determine the functional, technical, and business viability of using the technology throughout the semiconductor supply chain. Programmable-logic firm Altera and electronics component distributor SMT Corp. are participating in that round.

It is this phase of testing that addresses today’s primary counterfeit problem—obsolete parts. Since the 1990s, the U.S. military has increasingly relied on commercial off-the-shelf components. However, military systems are designed for the long haul—20 or 30 years. Commercial manufacturers typically don’t manufacture specific part numbers for that long, which means defense contractors and their suppliers often must turn to the “gray market” to find them. Unlike authorized distributors—who resell parts directly from the manufacturers—brokers and independent distributors buy parts on the open market and resell them. This is often how counterfeit parts enter the supply chain.

SMT finds and authenticates obsolete components for use by military and aerospace customers. The company uses expensive, sophisticated instruments, like US $250 000 scanning electron microscopes, to inspect a sample of the parts it gets on the open market before reselling them, says Tom Sharpe, vice president at the company. He likens the fight against counterfeits to an arms race, saying his company is constantly trying to stay one step ahead of the bad guys. According to Sharpe, the company has discovered four new counterfeiting methods in the past 18 months or so. “When it gets to a point where we have to have a piece of equipment that costs $250 000 to determine whether the part is real, it really says a lot for the counterfeit methods they have developed and how far this has come.”

In the tests, packaged chips have been marked with DNA at Altera’s production plant and then moved to SMT, which succeeded in scanning the chips for the DNA marking. Now SMT is applying the DNA markings to parts that it has sourced on the open market and that have passed its inspection process, essentially giving them a stamp of approval that authenticates the part from that point in the supply chain.

The effectiveness of this technology could depend on the stage at which the mark is incorporated and where it is placed. That’s because the production of electronics is so multifaceted and global. A chip may be manufactured at a foundry in Taiwan, packaged by another company in Vietnam, tested by a third company in Thailand, and placed on a motherboard in China, all before it ever reaches a customer in the United States.

A separate research program at the College of Nanoscale Science and Engineering (CNSE) of the University at Albany is addressing those complexities; the program has just launched a partnership with Applied DNA to develop nanotechnology-based methods to combat counterfeiting.

It’s one thing to mark the component package but quite another to mark the silicon die itself. The college and company are developing ways to deposit DNA onto processed silicon wafers. “This is an opportunity to start to verify if the DNA could be attached to the wafer during processing rather than at the point of packaging,” says Michael Fancher, CNSE’s vice president for business development and economic outreach.

The project will develop authentication protocols and procedures in semiconductor processes, including CMOS, MEMS, photonics, and advanced packaging technologies like 3-D wafer-to-wafer and die-on-wafer techniques.

Among the goals of the research is to identify how to attach a DNA mark to the wafer, where on the wafer to put it, and the best time during the manufacturing process to apply it.

About the Author

Tam Harbert is an award-winning journalist based in Washington, D.C., covering business, government, and technology.