Researchers at the U.S. Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab) have demonstrated that a free-standing single layer of molybdenum disulfide (MoS2) can exhibit the piezoelectric effect. The result could make possible new nanoscale low-power switches for sensors and other electronics.

The piezoelectric effect, in which compressing or stretching a material produces a voltage or where a voltage can cause a material to expand or contract, has been a mainstay for a range of electronic devices. But it has been limited to bulk crystals. This latest demonstration of the effect in a two-dimensional material promises to expand those applications.

“The discovery of piezoelectricity at the molecular level not only is fundamentally interesting, but also could lead to tunable piezo-materials and devices for extremely small force generation and sensing,” said Xiang Zhang, director of Berkeley Lab’s Materials Sciences Division, in a press release.

In October 2014, joint research out of Columbia University and Georgia Tech also demonstrated that MoS2 exhibits piezoelectricity and the piezotronic effect, which is the use of the piezoelectric effect as the gate voltage in transistor or similar device.

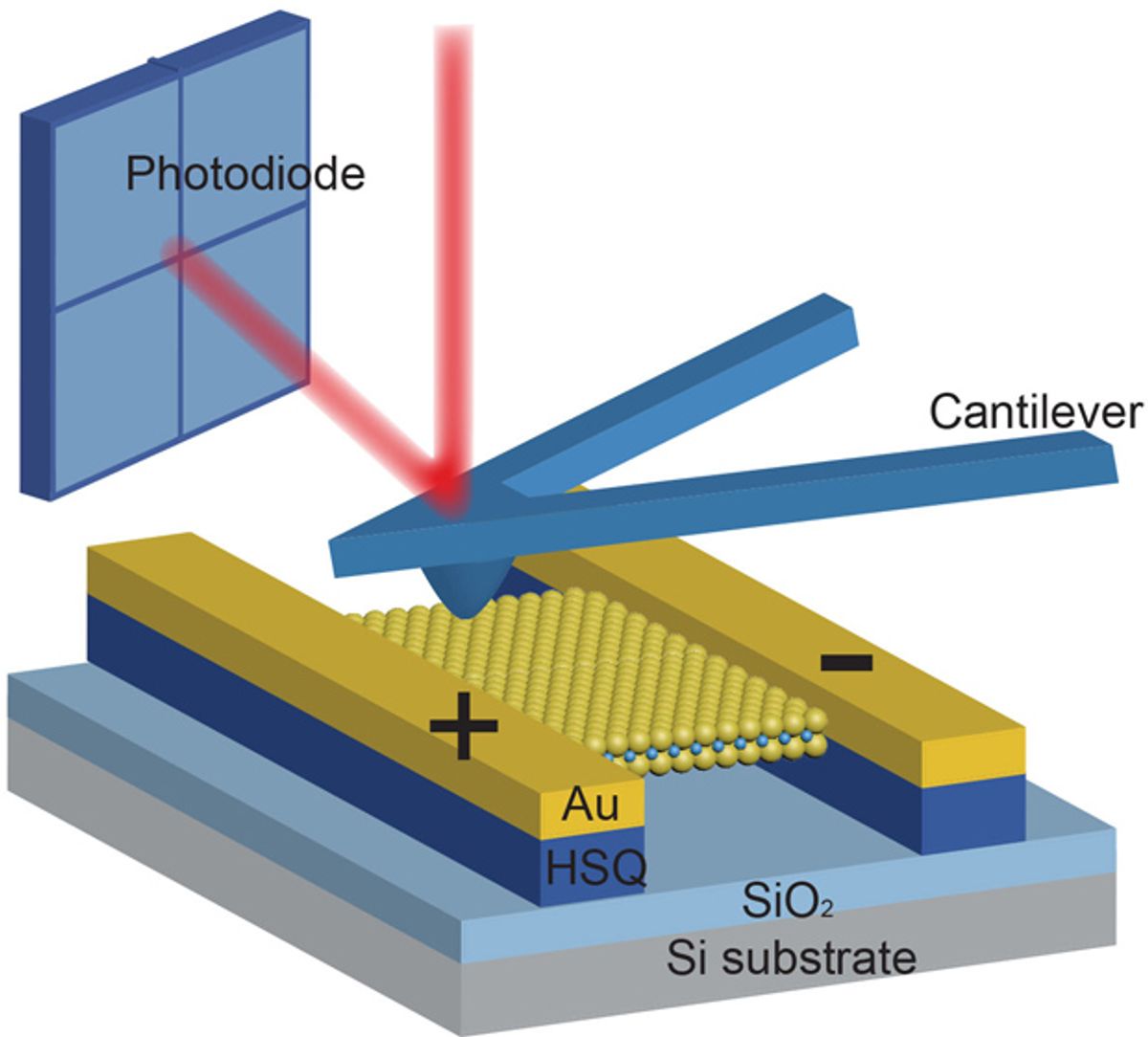

But in that research, the team at Columbia positioned thin flakes of MoS2 on flexible plastic substrates. In the new work out of Berkeley Lab, however, no substrate was used, and the researchers showed that free-standing MoS2 could demonstrate a piezoelectric effect.

In both efforts, the piezoelectric effect in MoS2 only appeared when an odd number of layers were used (1,3,5, etc.).

“This discovery is interesting from a physics perspective since no other material has shown similar layer-number sensitivity,” Hanyu Zhu, one of the co-authors of the research published in the journal Nature Nanotechnology, said in a press release. “The phenomenon might also prove useful for applications in which we want devices consisting of as few as possible material types, where some areas of the device need to be non-piezoelectric.”

In addition to logic switches and bio-sensors, the researchers believe that piezoelectricity in MoS2 could have an impact on the development of so-called “valleytronics.” Valleytronics essentially moves us away from the use of charge as a means for storing information and toward a scheme where we instead we encode data in the wave “quantum number” of an electron in a crystalline material. The term valleytronics refers to the fact that if you plotted the energy of electrons relative to their momentum on a graph, the resulting curve would feature two deep valleys.

The researchers are investigating the possibility of using piezoelectricity to directly control valleytronic properties in molybdenum disulfide.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.